Limestone-gypsum wet flue gas desulfurization synergist and preparation method thereof

A technology of wet flue gas desulfurization and synergist, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. Major and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

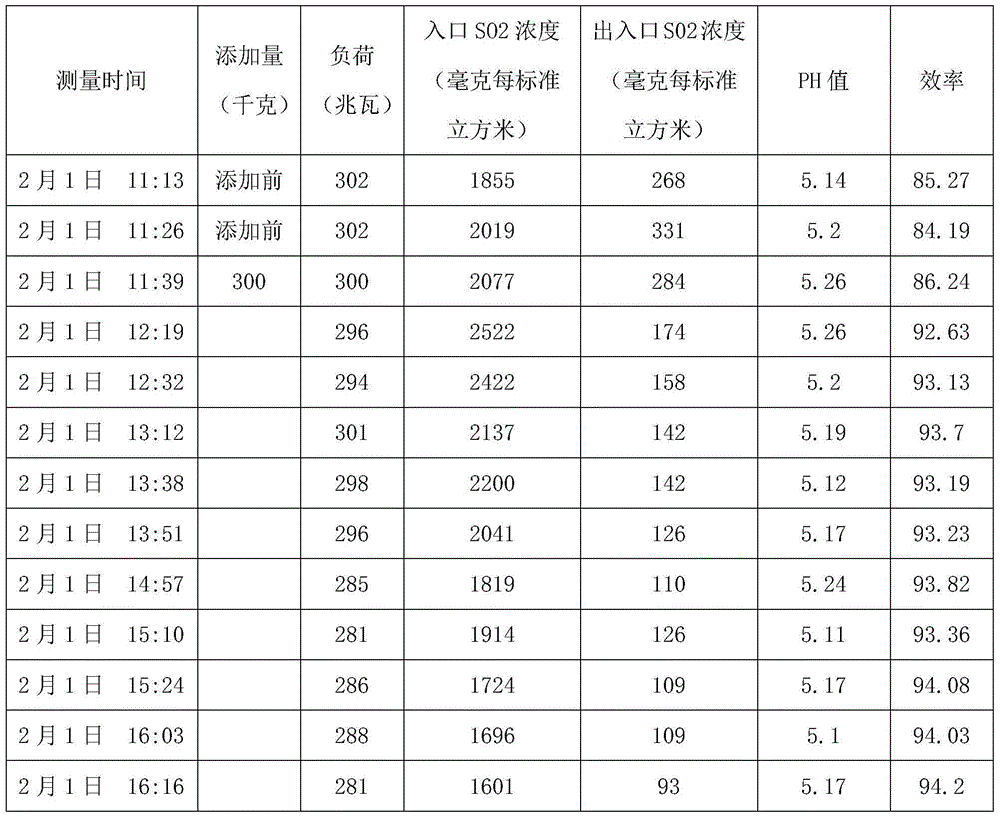

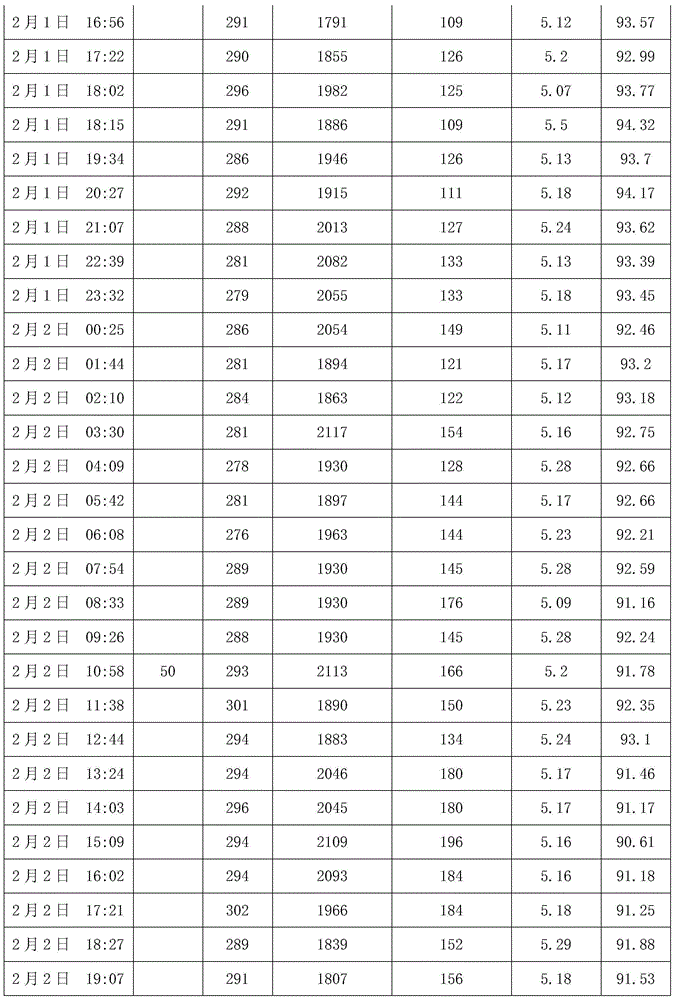

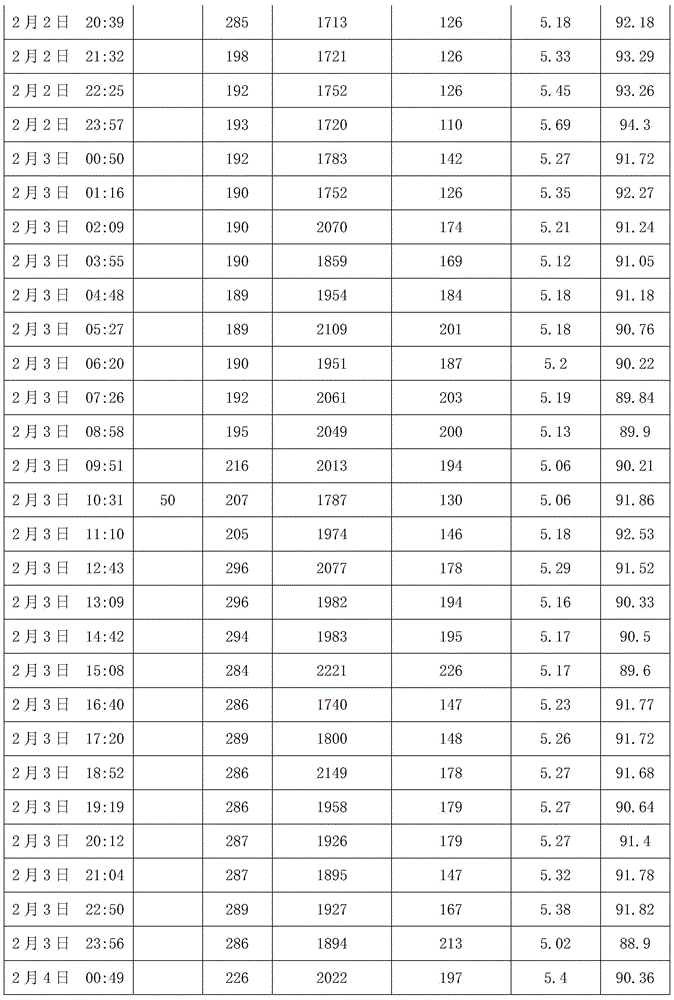

Image

Examples

Embodiment 1

[0021] Example 1, at normal temperature and pressure, weigh organic acid salt (70 kg of sodium diacetate), organic acid anhydride (5 kg of maleic anhydride) and surfactant (5 kg of polysiloxane) into the reactor Stir in the middle until uniform, that is, a limestone-gypsum wet-process flue gas desulfurization synergist of the present invention is obtained. During the production process, due to the large amount of powder, attention should be paid to the protection of flying powder. At the same time, when the limestone-gypsum wet-process flue gas desulfurization synergist is stored and transported, it should be placed in a cool and ventilated place, avoiding high temperature and prohibiting open storage.

[0022] The desulfurization synergist contains sodium diacetate, maleic anhydride and polysiloxane. Optimize the desulfurization process with the most simple, effective, economical and safe methods to improve the desulfurization performance of the FGD (fluegas desulphuration, ...

Embodiment 2

[0027] Example 2, under normal temperature and pressure, weigh 90 kilograms of sodium diacetate, 20 kilograms of maleic anhydride and 15 kilograms of polysiloxane and add it to the reactor and stir until uniform, so as to obtain a limestone- Gypsum wet flue gas desulfurization synergist.

Embodiment 3

[0028] Example 3, under normal temperature and pressure, weigh 80 kilograms of sodium diacetate, 15 kilograms of maleic anhydride and 10 kilograms of polysiloxane and add it to the reactor and stir until uniform, so as to obtain a limestone- Gypsum wet flue gas desulfurization synergist.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com