Device capable of realizing zero discharge of desulfurization wastewater

A desulfurization wastewater and zero-discharge technology, which is applied in general water supply conservation, gaseous effluent wastewater treatment, dehydration/drying/concentrated sludge treatment, etc., can solve problems such as environmental hazards, high design costs, and unfavorable industrialization promotion. Protect the ecological environment and achieve zero emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

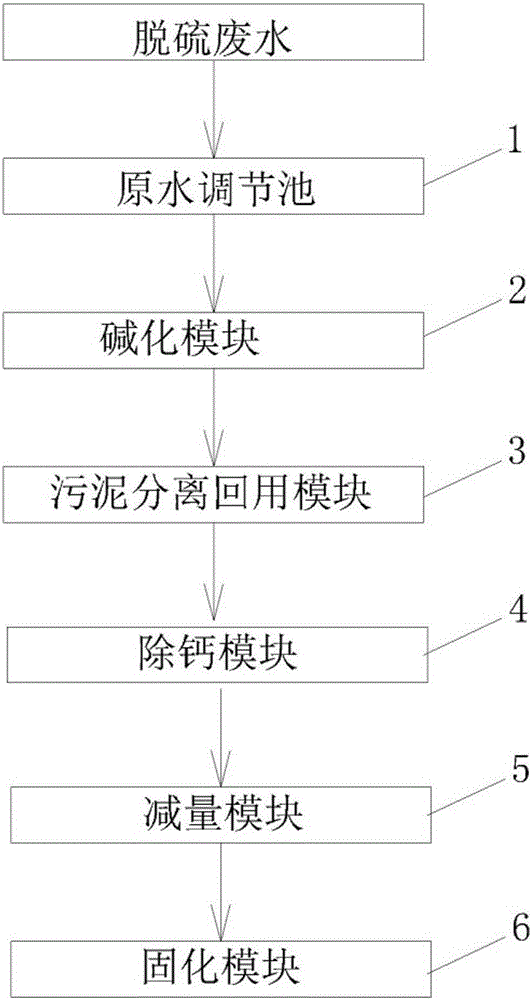

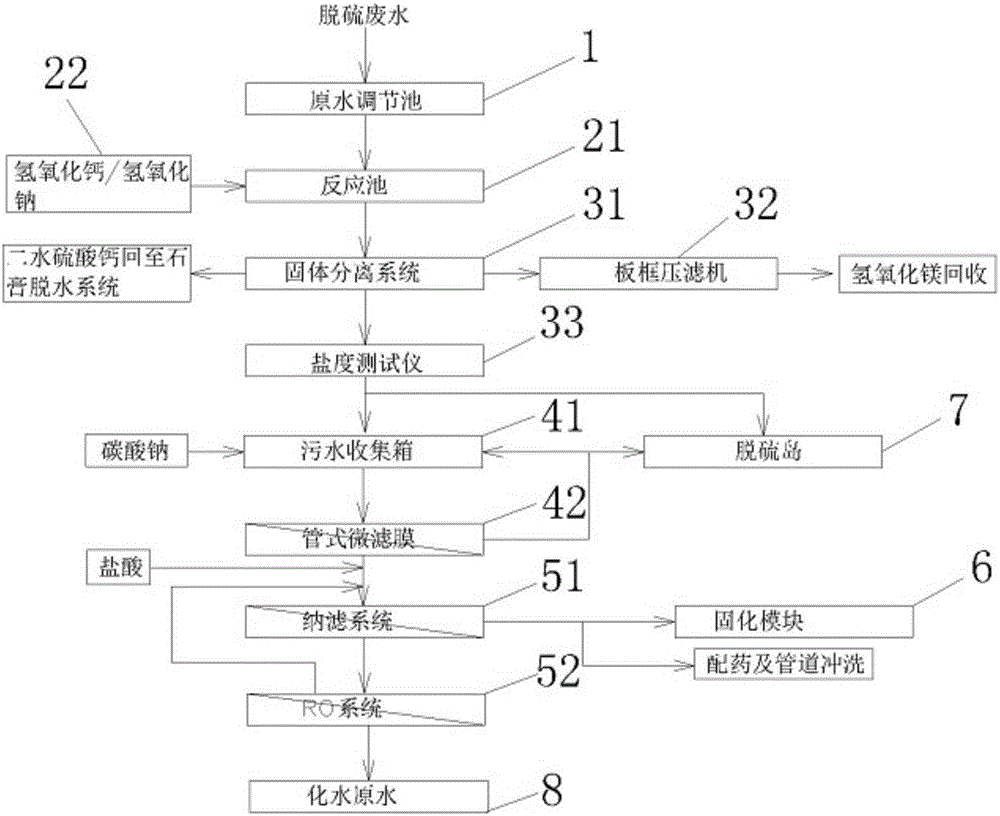

[0028] see figure 1 and figure 2 , a zero-discharge device for desulfurization wastewater in the present embodiment 1, comprising a raw water regulating tank 1, an alkalization module 2, a sludge separation and recovery module 3, a decalcification module 4, a reduction module 5 and a solidification module 6,

[0029] After the desulfurization wastewater passes through the raw water adjustment tank 1 to adjust the water volume, it enters the alkalization module 2, in which lime milk and / or sodium hydroxide are added to adjust the pH value of the water, and the flocculation reaction is carried out to remove the magnesium and sulfuric acid in the desulfurization wastewater The root ion precipitates to form flocs, and the alkalization module 2 includes a reaction tank 21. During the flocculation reaction, calcium hydroxide and sodium hydroxide 22 are added to the reaction tank 21 to adjust the pH value in the reaction tank to be greater than 10, and the flocculation reaction form...

Embodiment 2

[0037] refer to figure 1 and figure 2 As shown, the basic structure of this embodiment is roughly the same as that of Embodiment 1, the difference is that the decalcification module 4 in this embodiment includes a sewage collection box and a tubular microfiltration membrane system, and the desulfurization wastewater enters the sewage collection box, The desulfurized flue gas is extracted in the sewage collection box for aeration, and the carbon dioxide in the flue gas reacts with the calcium ions in the waste water. At the same time, sodium hydroxide is added to maintain the pH value of the waste water above 10.0. The effluent from the sewage collection box enters the tubular microfiltration membrane system for Solid-liquid separation, the wastewater from the clear water side of the tubular microfiltration membrane system enters the back-end reduction module 5, and the wastewater from the concentrated water side of the tubular microfiltration membrane system has a high solid ...

Embodiment 3

[0040] refer to figure 1 and figure 2 As shown, in the present embodiment 3, the salinity tester is an online salinity meter, and the desulfurization wastewater with a salinity lower than 10000mg / L is returned to the desulfurization island, and the salinity is higher than the high salinity wastewater of 20000mg / L The desulfurization waste water enters the waste water collection tank, and the salinity is 10000mg / L~30000mg / L, respectively enters the desulfurization island and the waste water collection tank according to the ratio. Wastewater collection tank.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com