Preparation process of cyclohexanone-oxime

A technology for the preparation of cyclohexanone oxime, which is applied in oxime preparation, chemical recovery, organic chemistry, etc., can solve the problems of increased energy consumption, and achieve the effects of reduced consumption, high quality, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

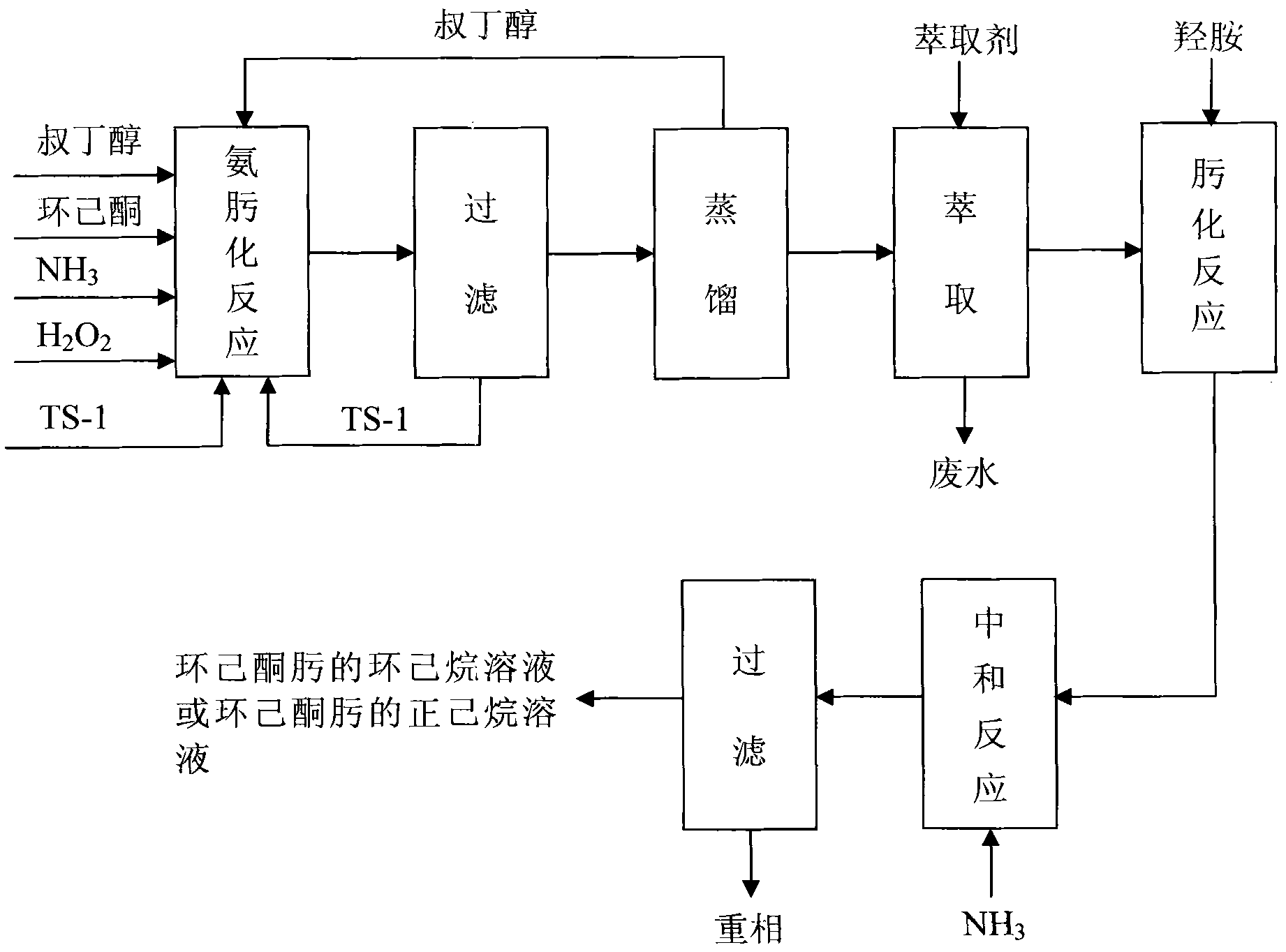

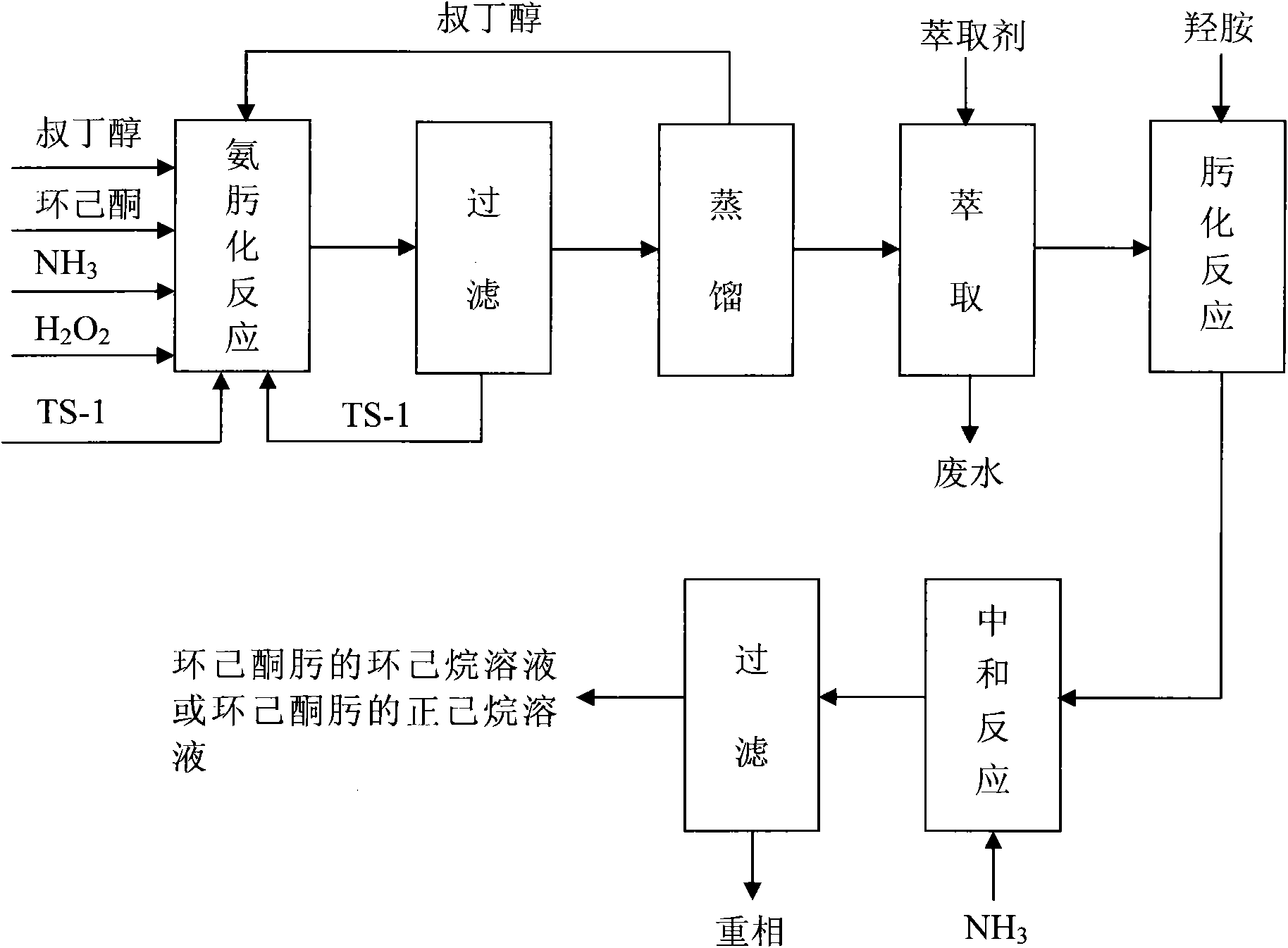

[0023] Embodiment 1: as figure 1 Shown, technological process of the present invention comprises the steps:

[0024] a.10920kg / h cyclohexanone, 2012kg / h ammonia, 15127kg / h 27.5% hydrogen peroxide enter the ammoximation reactor at the same time, in the presence of molecular sieve catalyst TS-1 and solvent tert-butanol (TBA) and 80~90℃ , Under the condition of 0.4~0.6Mpa, ammoximation reaction occurs;

[0025] b. When the conversion rate of cyclohexanone in the above reaction is 99.5%, it is separated by filtration, wherein the catalyst separated by filtration returns to the ammoximation reactor and continues to be used as catalyst recycling, and the filtrate separated by filtration goes to the tert-butanol distillation tower for distillation. The solvent tert-butanol that goes out is returned to the ammoximation reactor and continues to be used as a reaction solvent for recycling;

[0026] c. the mixed solution of cyclohexanone / cyclohexanone oxime / water coming out from the bo...

Embodiment 2

[0030] Embodiment 2: the difference between this embodiment and embodiment 1 is that the cyclohexane extractant is replaced by n-hexane extractant.

Embodiment 3

[0031] Embodiment 3: The difference between this embodiment and Example 1 is that the 13.8% hydroxylamine phosphate of 457kg / h is used to replace the 19.7% hydroxylammonium sulfate of 457kg / h during the second step oximation, obtained after ammonia neutralization and separation The salt-containing heavy phase is sent to hydroxylamine to prepare and recover phosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com