Method for recycling nickel-cobalt-manganese-lithium from waste power lithium ion battery black powder

A lithium-ion battery, nickel-cobalt-manganese-lithium technology, which is applied in the field of recycling waste lithium-ion power batteries, can solve problems such as low recovery rate and entrainment loss of lithium elements, so as to reduce recycling cost, improve recycling utilization rate, and scientific recycling process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

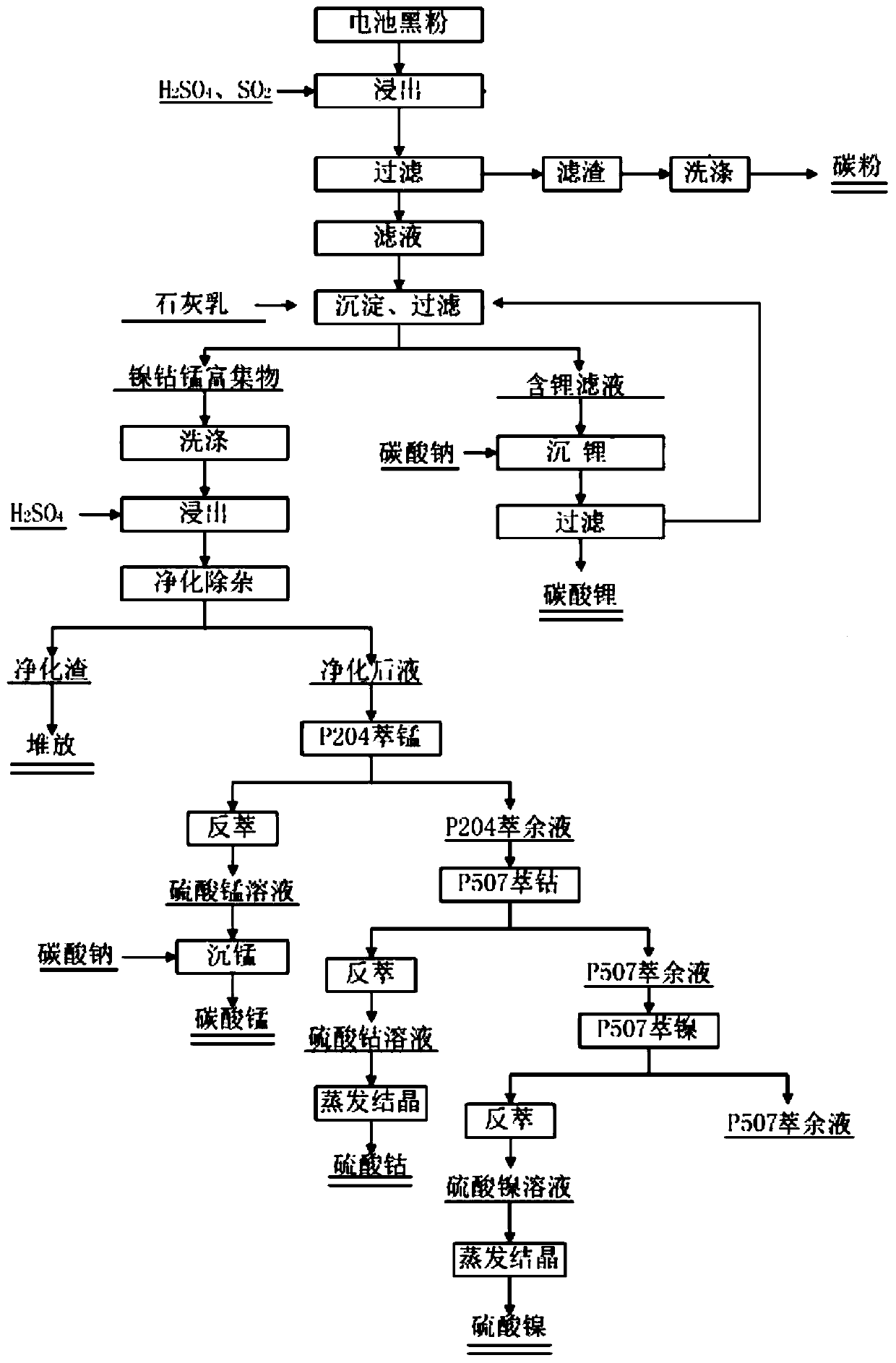

[0025] The power lithium-ion battery to be recycled is produced by Shenzhen BAK Battery Co., Ltd. The ternary positive electrode material is nickel-cobalt lithium manganese oxide. The recycling process is as follows: figure 1 As shown, the specific steps are as follows:

[0026] First, soak the power battery in a saturated sodium chloride solution to fully discharge it to remove residual electricity. After discharging, it is dried and disassembled in a fume hood, and then processed by crushing and sorting equipment to obtain a mixture of Battery black powder of positive and negative electrode materials, the black powder mainly includes positive electrode nickel, cobalt, manganese, lithium compounds and negative electrode carbon powder.

[0027] 1.H 2 SO 4 +SO 2 system leaching

[0028] Take 50g of black powder, place it in a wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com