Melt-blown polypropylene as well as preparation method and application thereof

A polypropylene and polypropylene resin technology, applied in the field of melt-blown polypropylene and its preparation, can solve the problems of adverse effects on human health and high gas resistance of melt-blown non-woven fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

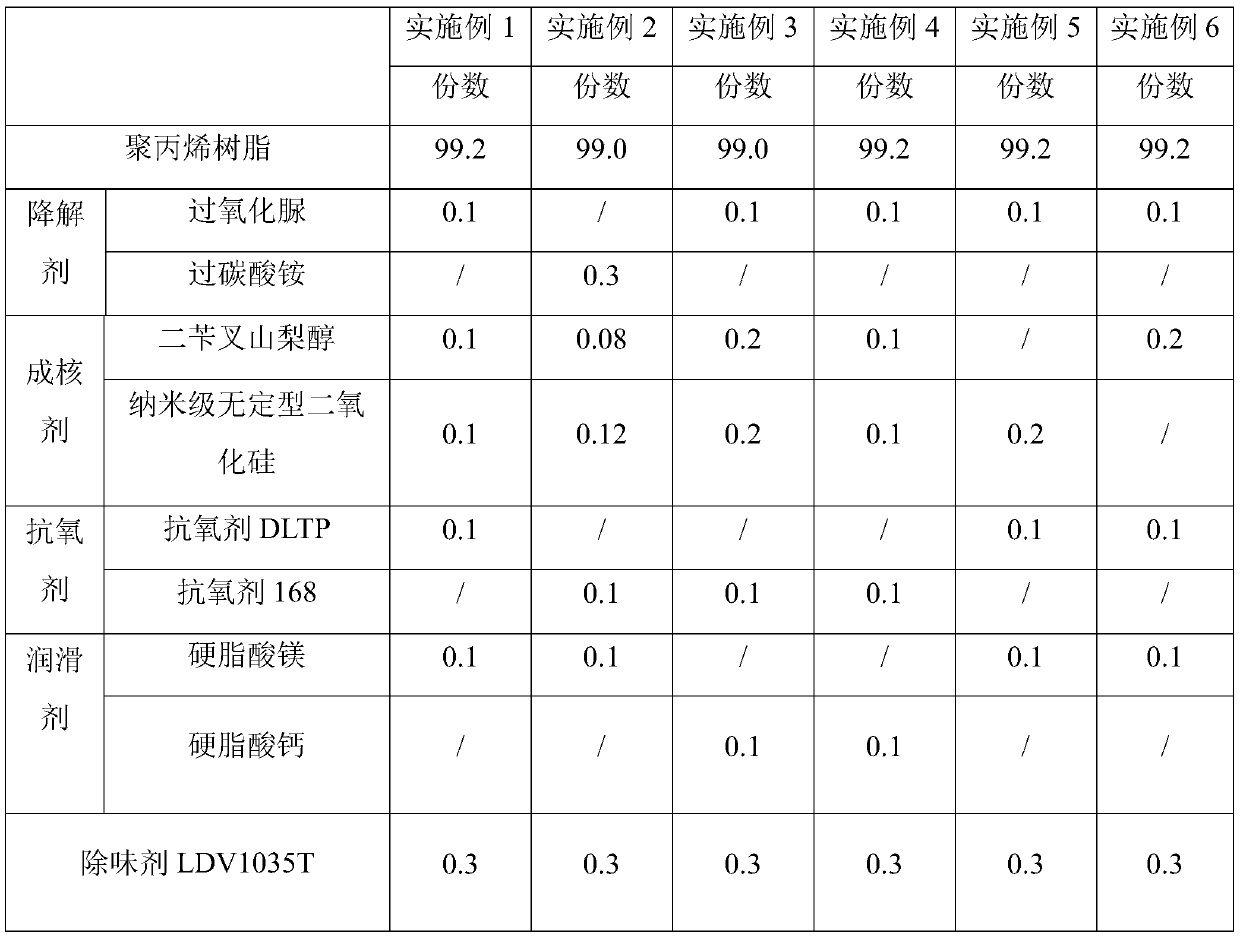

[0034] These examples provide a melt-blown grade polypropylene, and the specific raw materials and dosage are shown in Table 1 below.

[0035] Table 1

[0036]

[0037] The preparation method of the above-mentioned melt-blown polypropylene is as follows: weigh each raw material according to the formula, add the weighed polypropylene resin, degradation agent, nucleating agent, antioxidant and lubricant into the mixer for pre-mixing, and stir for 2 minutes , and then add deodorant; through twin-screw extruder melt blending reaction extrusion, feed rate 200kg / h, barrel temperature set 200-230 ℃, screw speed 350rpm, granulation, 80 ℃ hot air drying, production into the melt-blown grade polypropylene; wherein, the length-to-diameter ratio of the extruder is 50, and the homogenization section of the extruder is equipped with a vacuum devolatilization device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com