Method for preparing electronic ternary material precursor from Ni-Co residues

A ternary material, nickel-cobalt slag technology, applied in electrical components, circuits, battery electrodes, etc., can solve the problems of large new increments, large storage capacity, environmental impact, etc., and achieve the effect of reducing the purification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

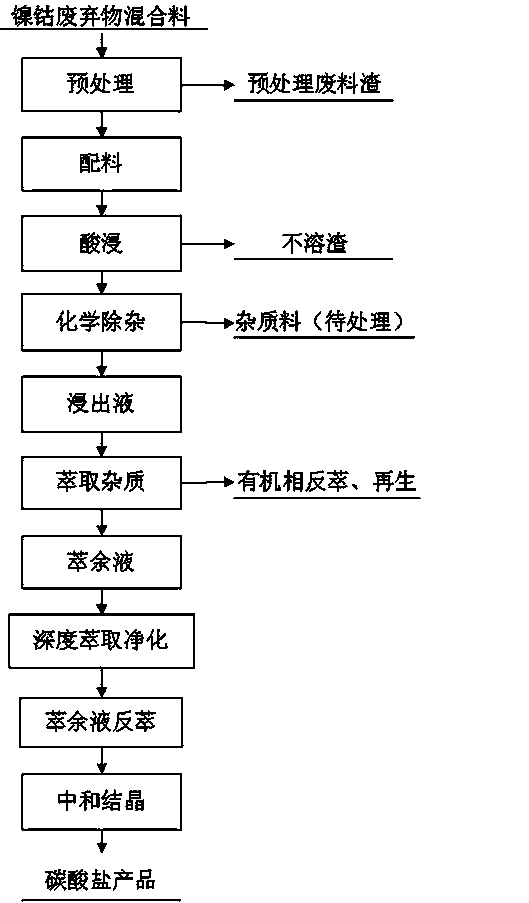

Method used

Image

Examples

example 2

[0054] A petrochemical enterprise’s catalyst waste, containing nickel, cobalt, aluminum, vanadium, molybdenum, etc., adopts the combined process of basic roasting method + water leaching method. The waste catalyst is mixed with a certain amount of caustic soda, the ingredient ratio is 1: 0.3, and the roasting temperature is 700 ℃, roasting time 1h, the produced calcine is leached in water with a liquid-to-solid ratio of 1:0.5. The aluminum, vanadium, and molybdenum are leached with water to enter the leaching solution, while nickel and cobalt are concentrated in the water leaching residue. The leaching temperature is 90℃, the leaching time is 5h, and the leaching residue is obtained by filtration, which is called 1# slag.

[0055] The waste nickel-hydrogen battery waste is separated by manual machinery to obtain nickel-cobalt slag, called 2# slag.

[0056] Nickel-cobalt slag produced by a metallurgical enterprise, containing nickel, cobalt, zinc, etc., was crushed to 250 mesh, and ...

example 1

[0066] According to the pretreated materials of various nickel and cobalt wastes, batching is carried out. For example, one of the batching processes can be used as follows:

[0067] Take 50 grams of 1# slag

[0068] Take 50 grams of 2# slag

[0069] Take 50 grams of 3# slag

[0070] Take 100 grams of 4# slag

[0071] Take 90 grams of 5# slag

[0072] 5. Ingredients example 2:

[0073] According to the needs of customers of ternary electronic materials for the ratio of nickel and cobalt, combined with the content of nickel and cobalt in various nickel and cobalt slags, the ratio between nickel and cobalt is adjusted. Two or three or four of the above 1# to 5# slag can be selected for batching, and the nickel-cobalt ratio can be adjusted appropriately. It can overcome the inconsistency of nickel and cobalt ratio in various slag types in nickel and cobalt waste. Through the design adjustment of the ingredients, the mol ratio between nickel and cobalt can reach 1:(0.2-1).

[0074] 6. Examp...

example 2

[0077] The mixed nickel-cobalt slag obtained after the above-mentioned ingredients is finely ground through a ball milling process, the particle size is <200 mesh. The fine abrasive is leached with sulfuric acid, the liquid-to-solid ratio is 7:1, the leaching temperature is 70°C, the leaching time is 1 hour, the amount of sulfuric acid is 1.6 times the theoretical amount, and the end point acidity pH=3.5-5 is maintained. Through sulfuric acid leaching, nickel and cobalt enter the sulfuric acid solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com