Patents

Literature

100results about How to "No memory effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Implantable devices using rechargeable zero-volt technology lithium-ion batteries

InactiveUS7184836B1Assures safe and reliable operation of systemFirmly connectedElectrotherapyLoad circuitLow voltage

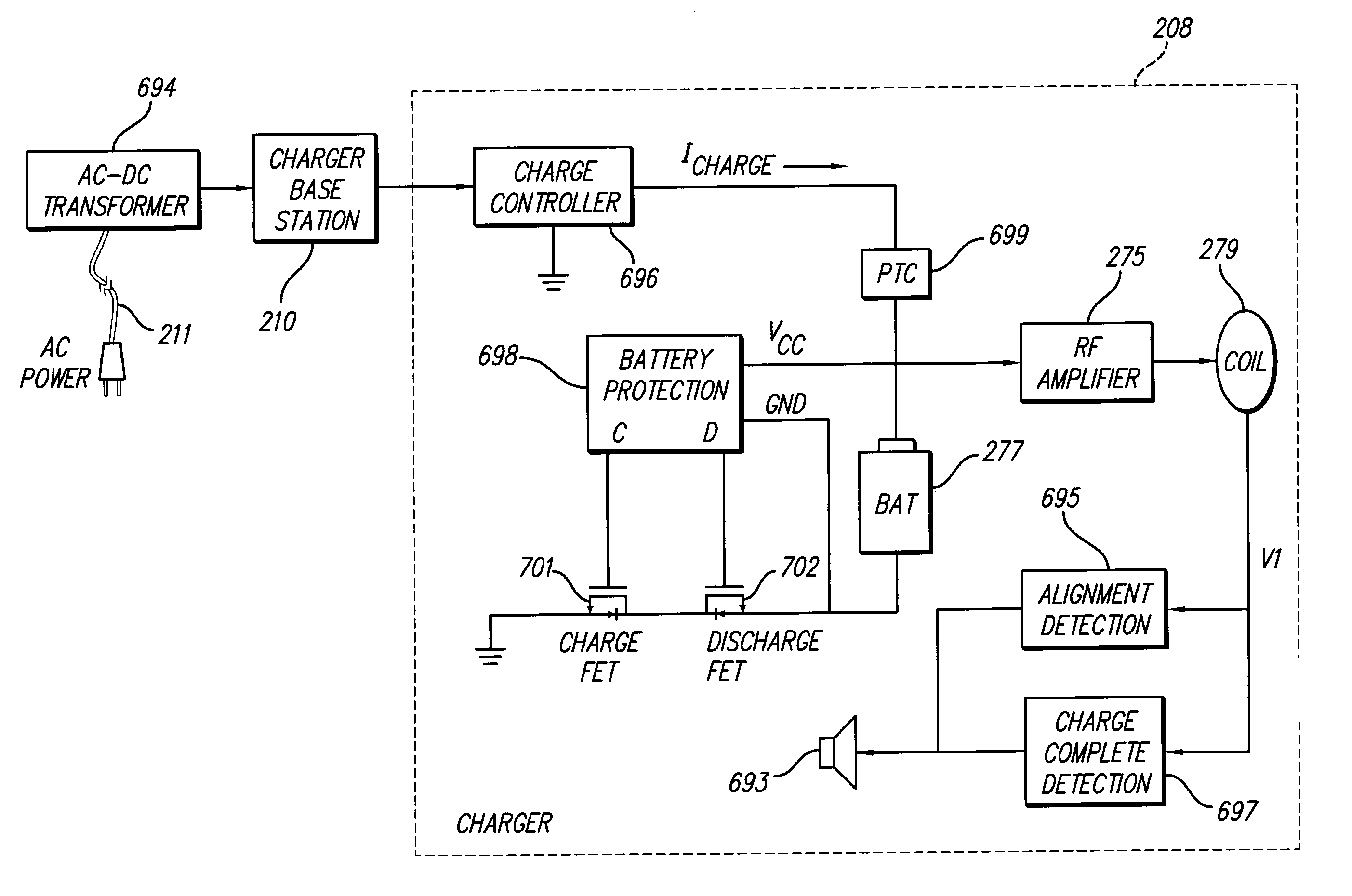

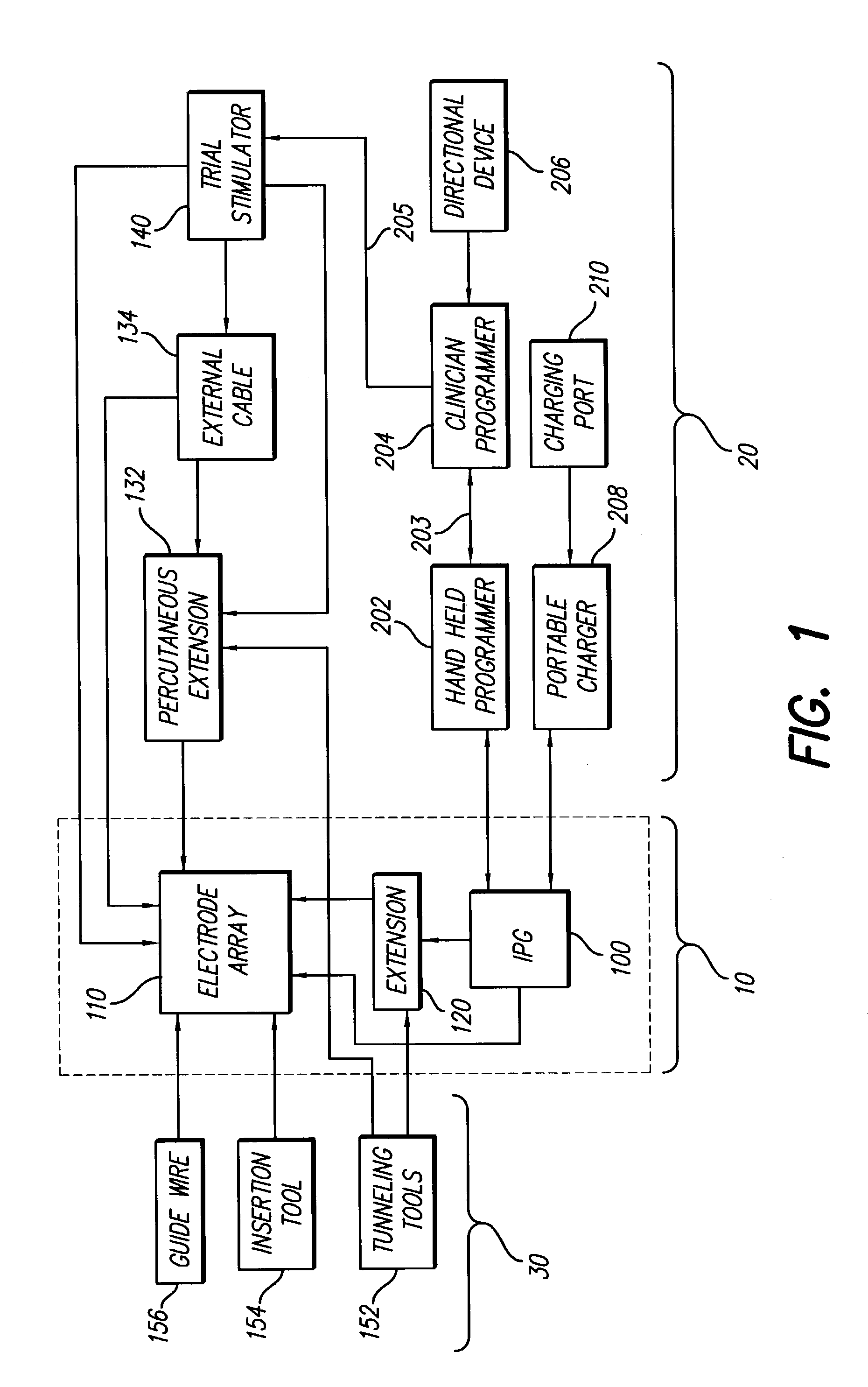

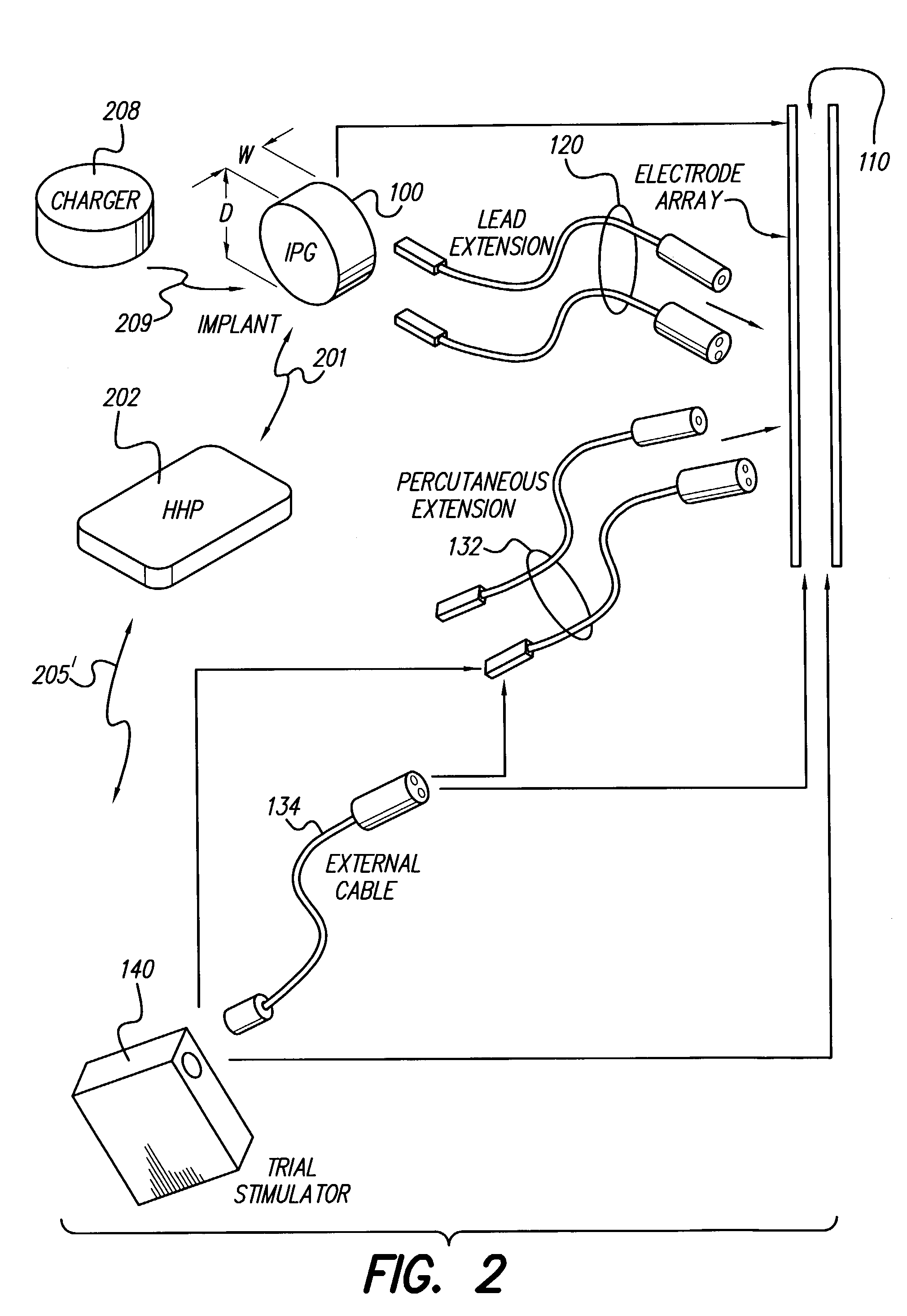

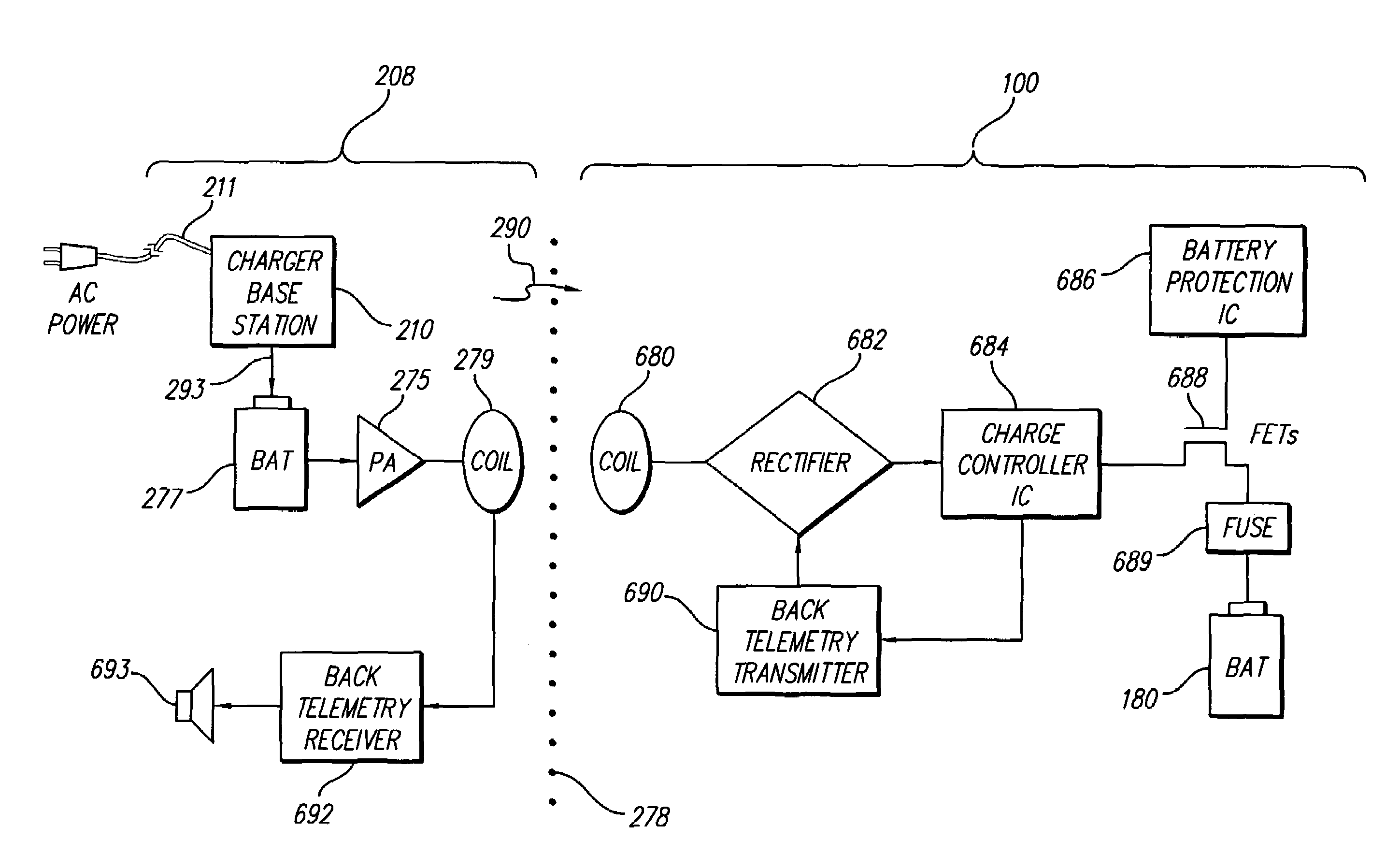

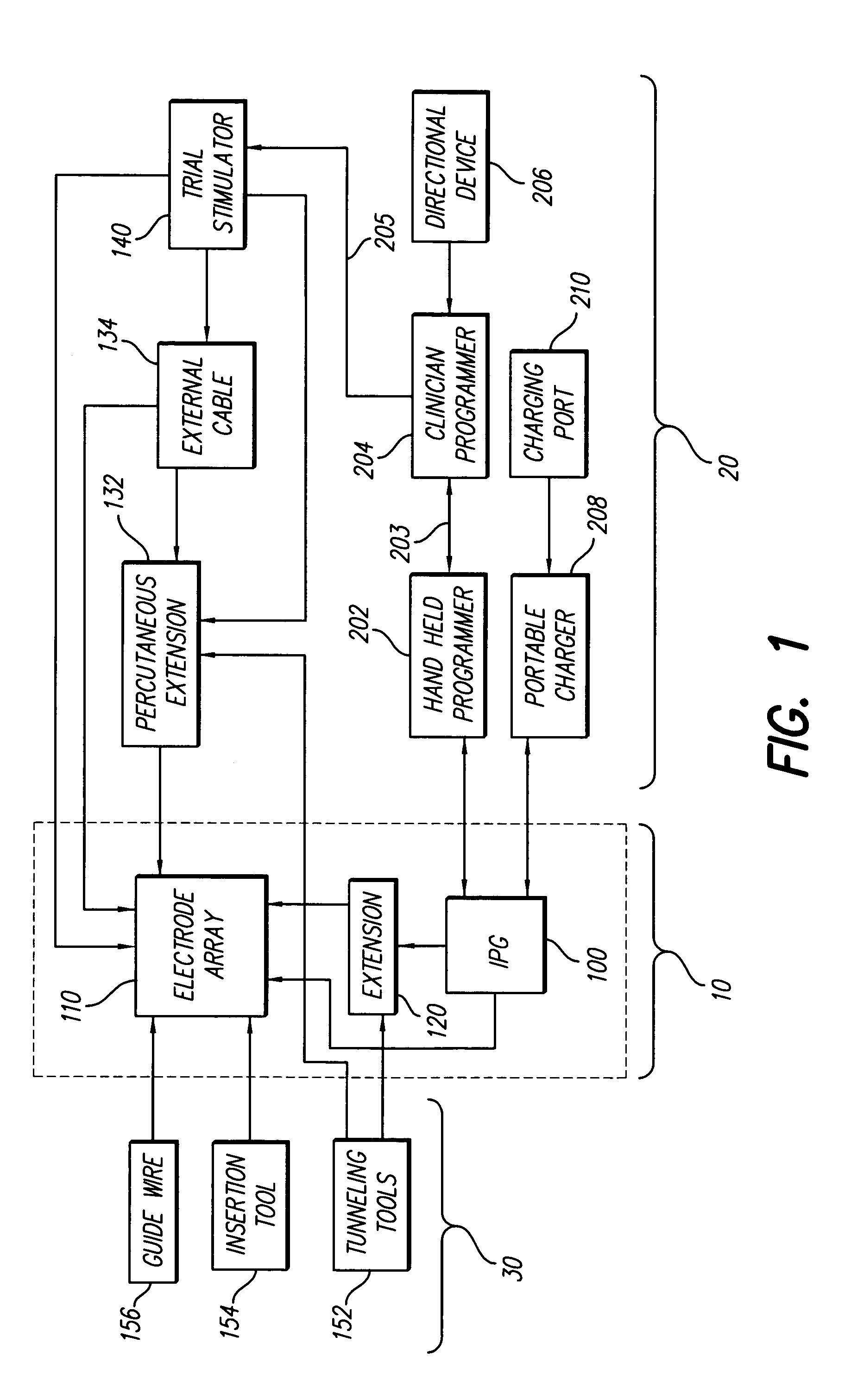

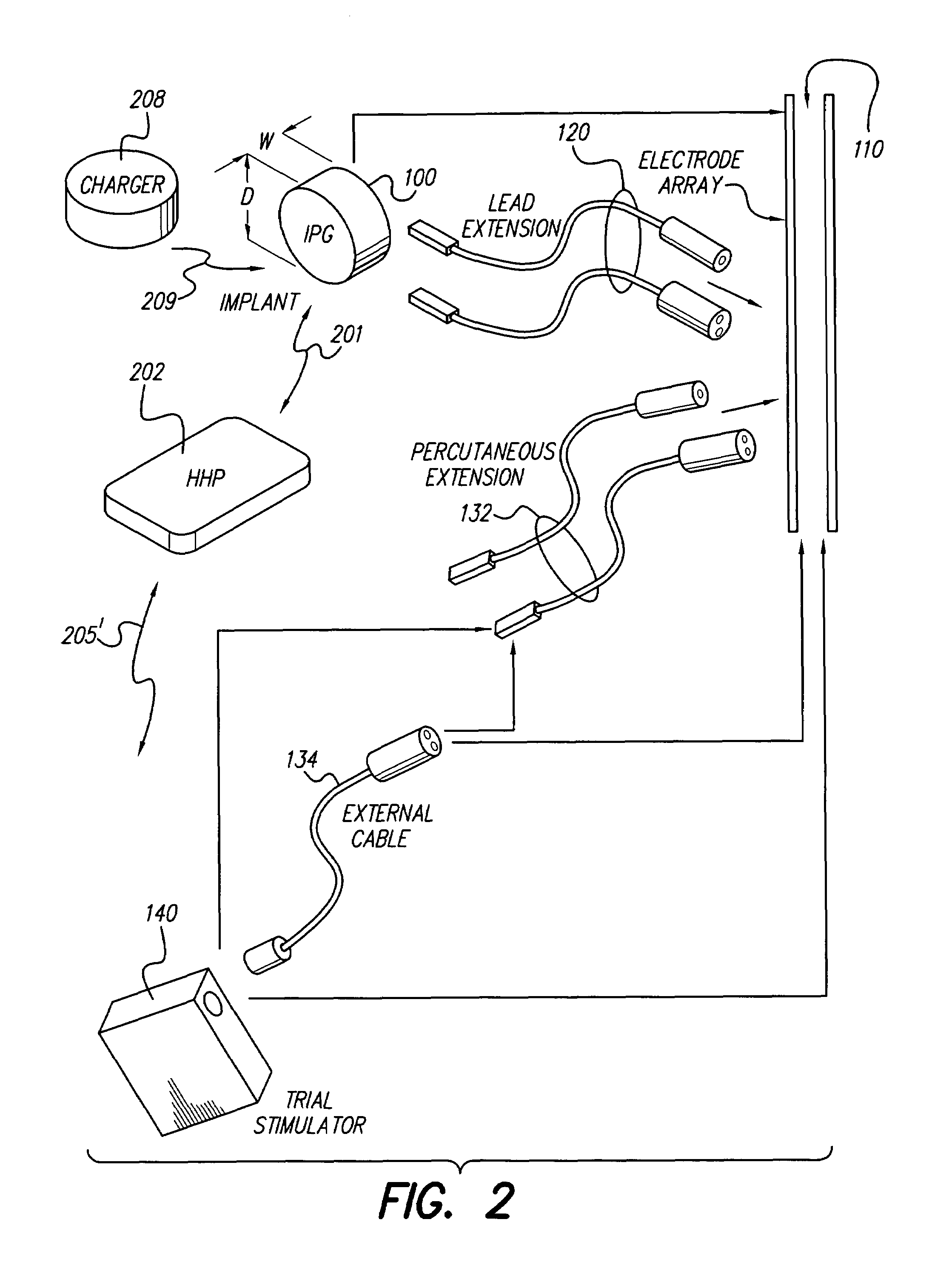

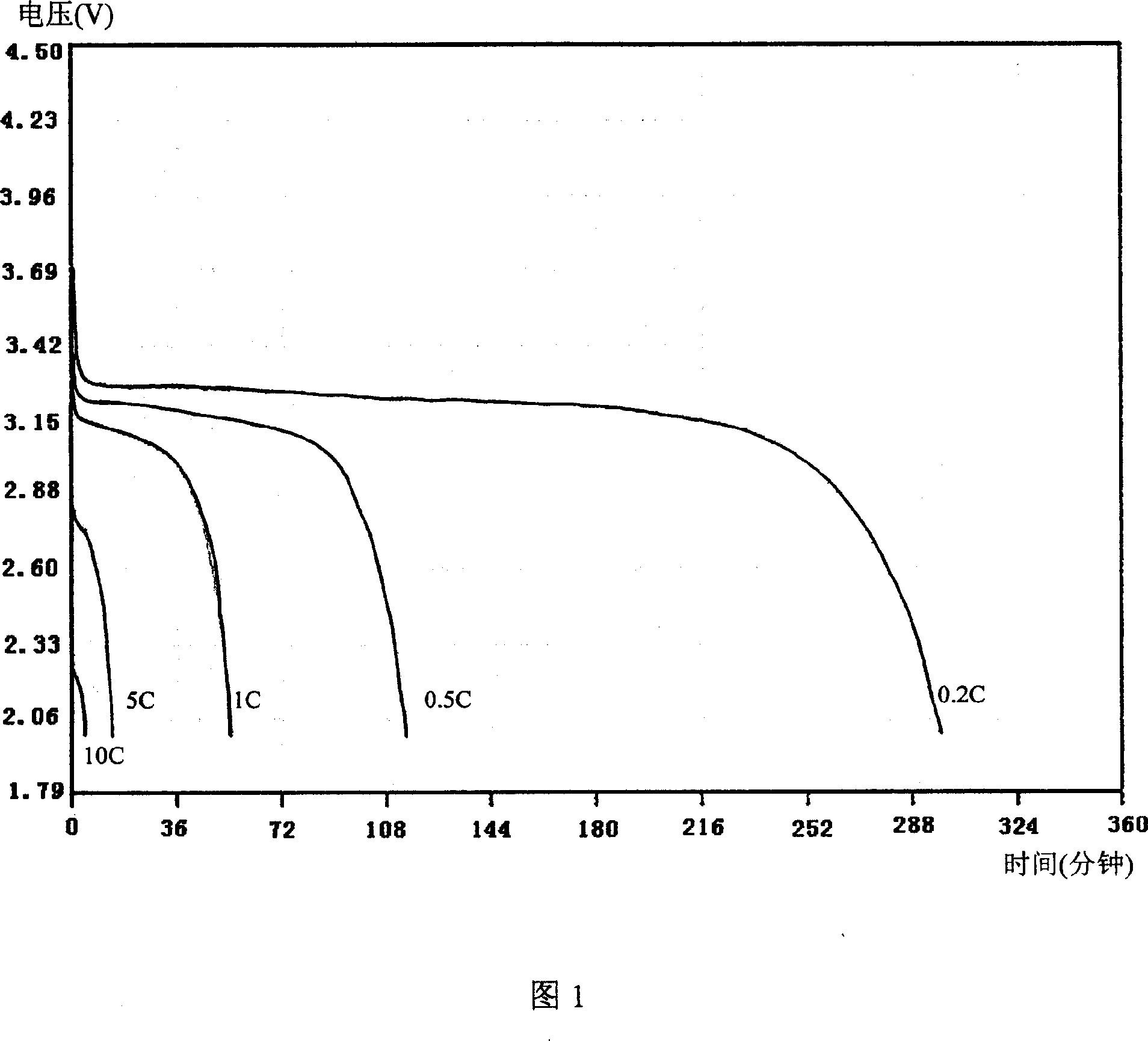

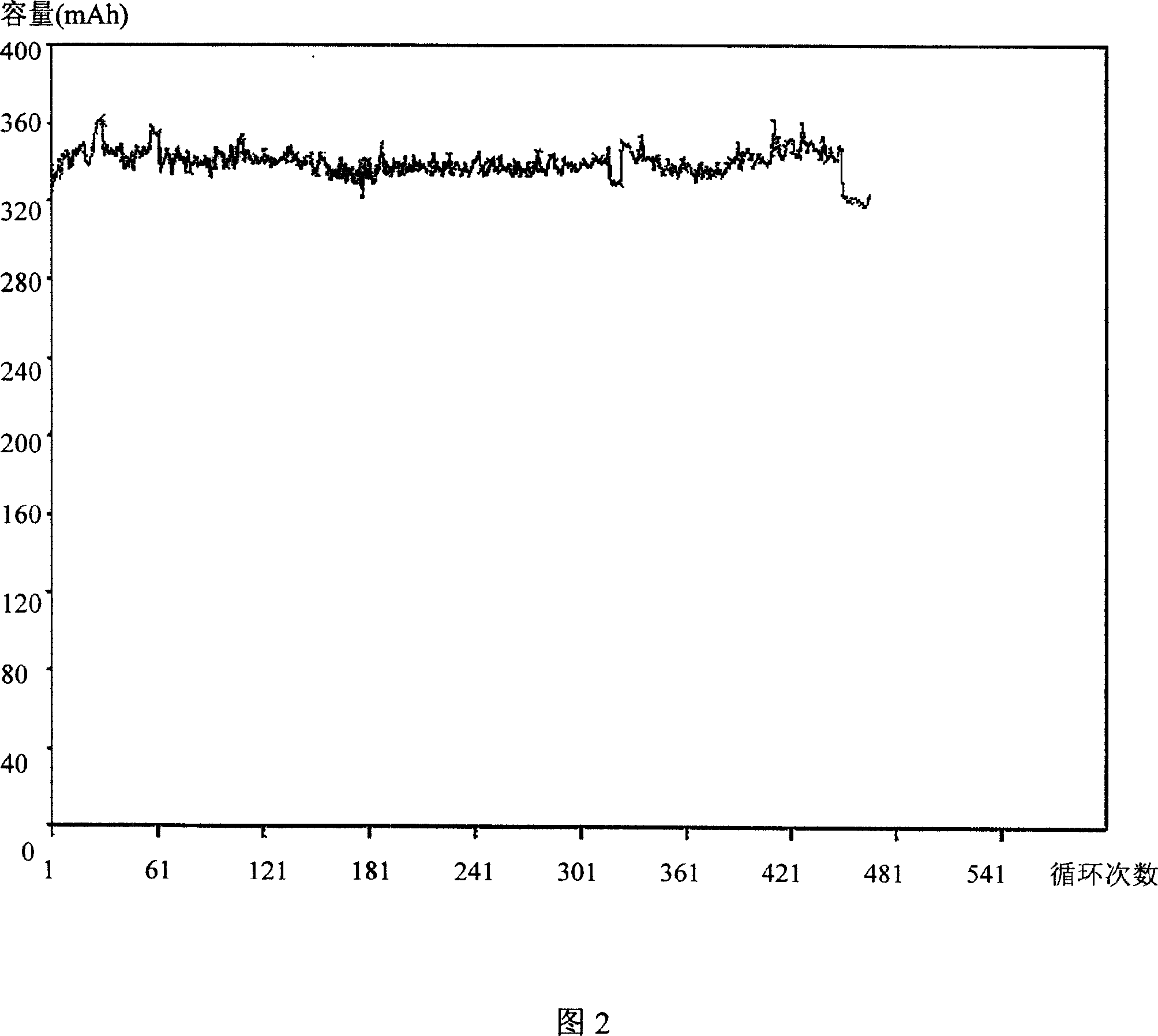

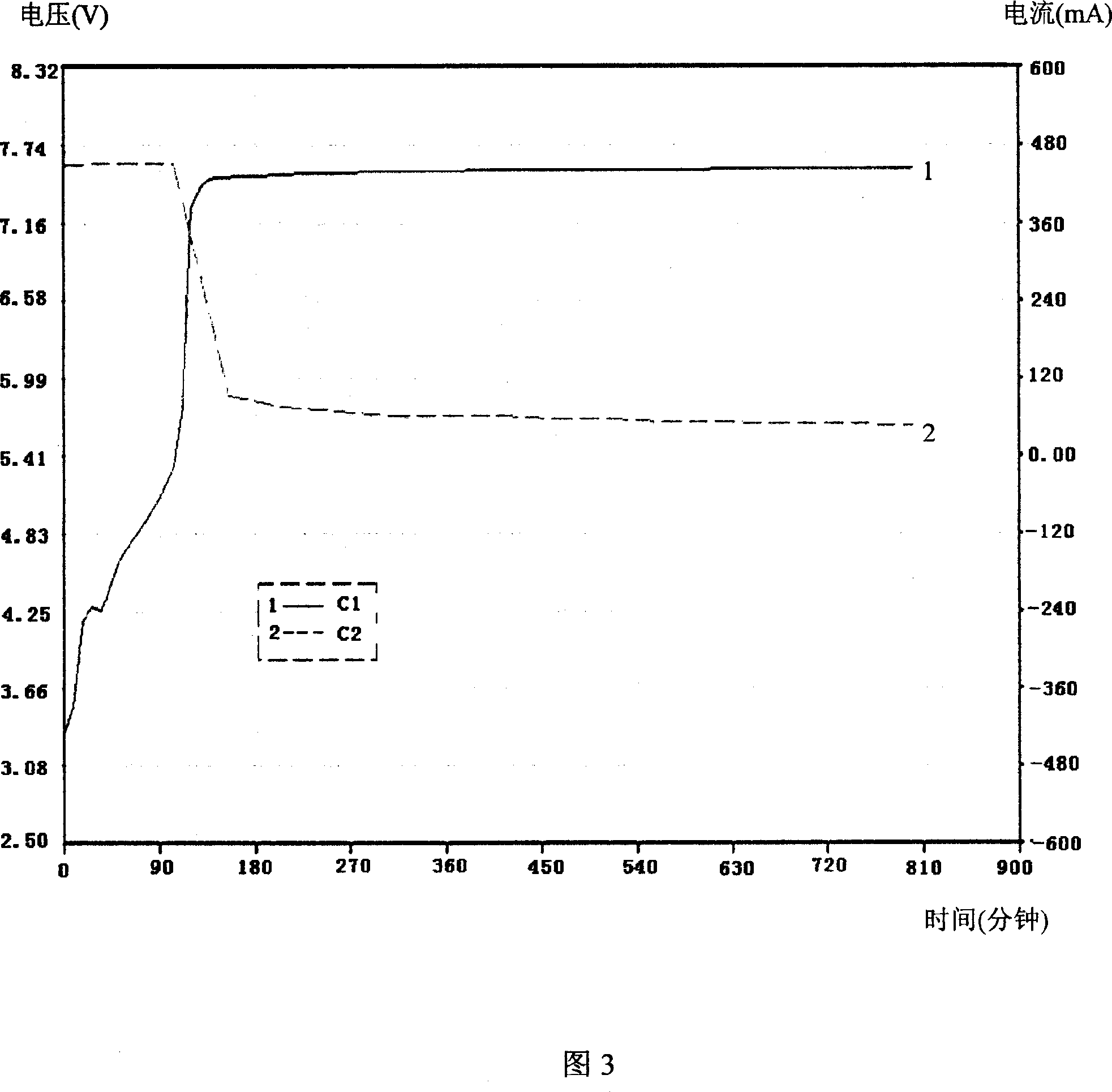

An implantable medical device, such as an implantable pulse generator (IPG) used with a spinal cord stimulation (SCS) system, includes a rechargeable lithium-ion battery having an anode electrode with a substrate made substantially from titanium. Such battery construction allows the rechargeable battery to be discharged down to zero volts without damage to the battery. The implantable medical device includes battery charging and protection circuitry that controls the charging of the battery so as to assure its reliable and safe operation. A multi-rate charge algorithm is employed that minimizes charging time while ensuring the battery cell is safely charged. Fast charging occurs at safer lower battery voltages (e.g., battery voltage above about 2.5 V), and slower charging occurs when the battery nears full charge higher battery voltages (e.g., above about 4.0 V). When potentially less-than-safe very low voltages are encountered (e.g., less than 2.5 V), then very slow (trickle) charging occurs to bring the battery voltage back up to the safer voltage levels where more rapid charging can safely occur. The battery charging and protection circuitry also continuously monitors the battery voltage and current. If the battery operates outside of a predetermined range of voltage or current, the battery protection circuitry disconnects the battery from the particular fault, i.e. charging circuitry or load circuits.

Owner:QUALLION +1

Implantable devices using rechargeable zero-volt technology lithium-ion batteries

InactiveUS7295878B1Assures safe and reliable operation of systemFirmly connectedImplantable neurostimulatorsLoad circuitLow voltage

An implantable medical device, such as an implantable pulse generator (IPG) used with a spinal cord stimulation (SCS) system, includes a rechargeable lithium-ion battery having an anode electrode with a substrate made substantially from titanium. Such battery construction allows the rechargeable battery to be discharged down to zero volts without damage to the battery. The implantable medical device includes battery charging and protection circuitry that controls the charging of the battery so as to assure its reliable and safe operation. A multi-rate charge algorithm is employed that minimizes charging time while ensuring the battery cell is safely charged. Slow charging occurs at lower battery voltages (e.g., battery voltage below about 2.5 V), and fast charging occurs when the battery voltage has reached a safe level (e.g., above about 2.5 V). When potentially less-than-safe very low voltages are encountered (e.g., less than 2.5 V), then very slow (trickle) charging occurs to bring the battery voltage back up to the safer voltage levels where more rapid charging can safely occur. The battery charging and protection circuitry also continuously monitors the battery voltage and current. If the battery operates outside of a predetermined range of voltage or current, the battery protection circuitry disconnects the battery from the particular fault, i.e. charging circuitry or load circuits.

Owner:QUALLION +1

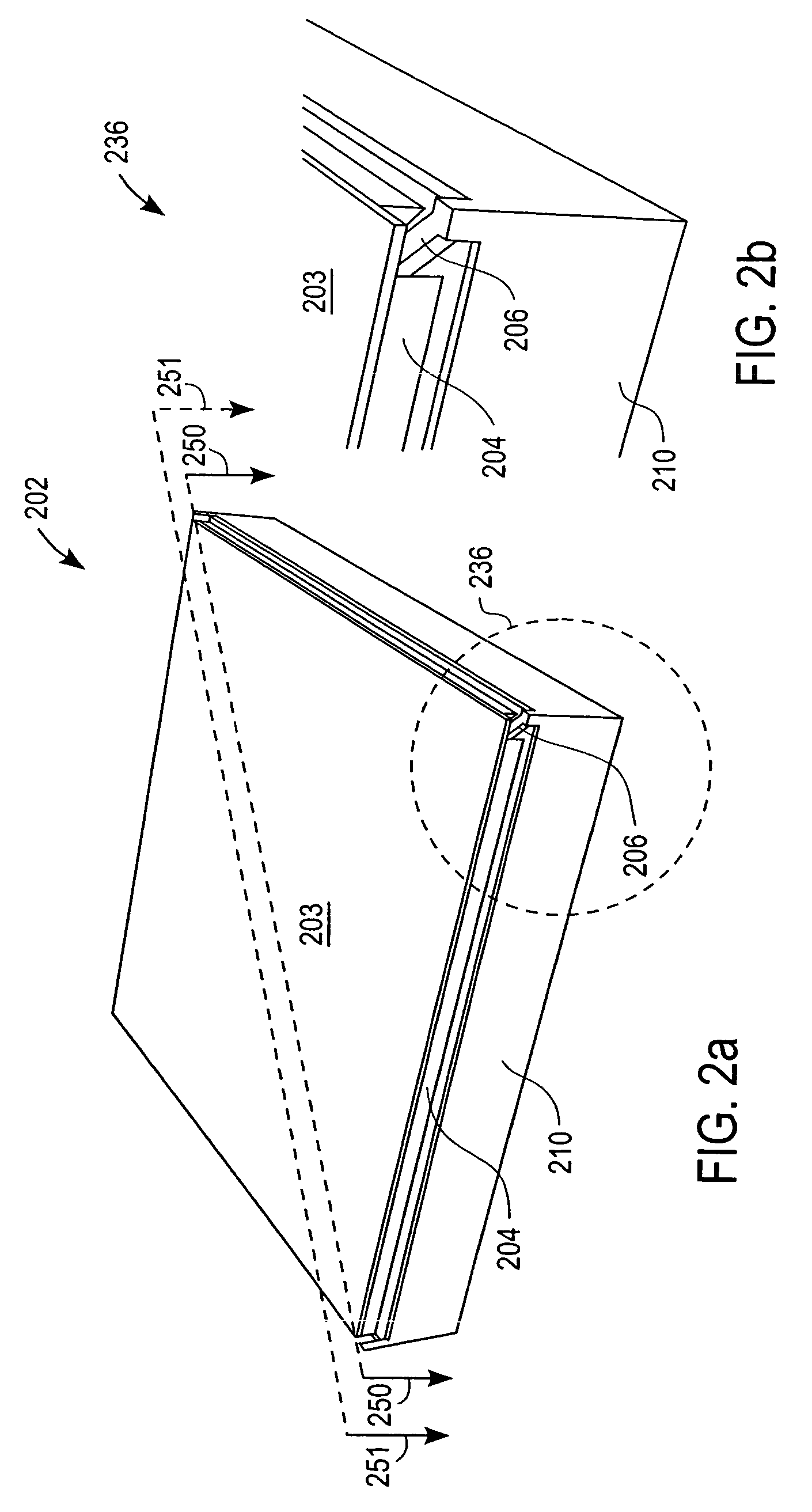

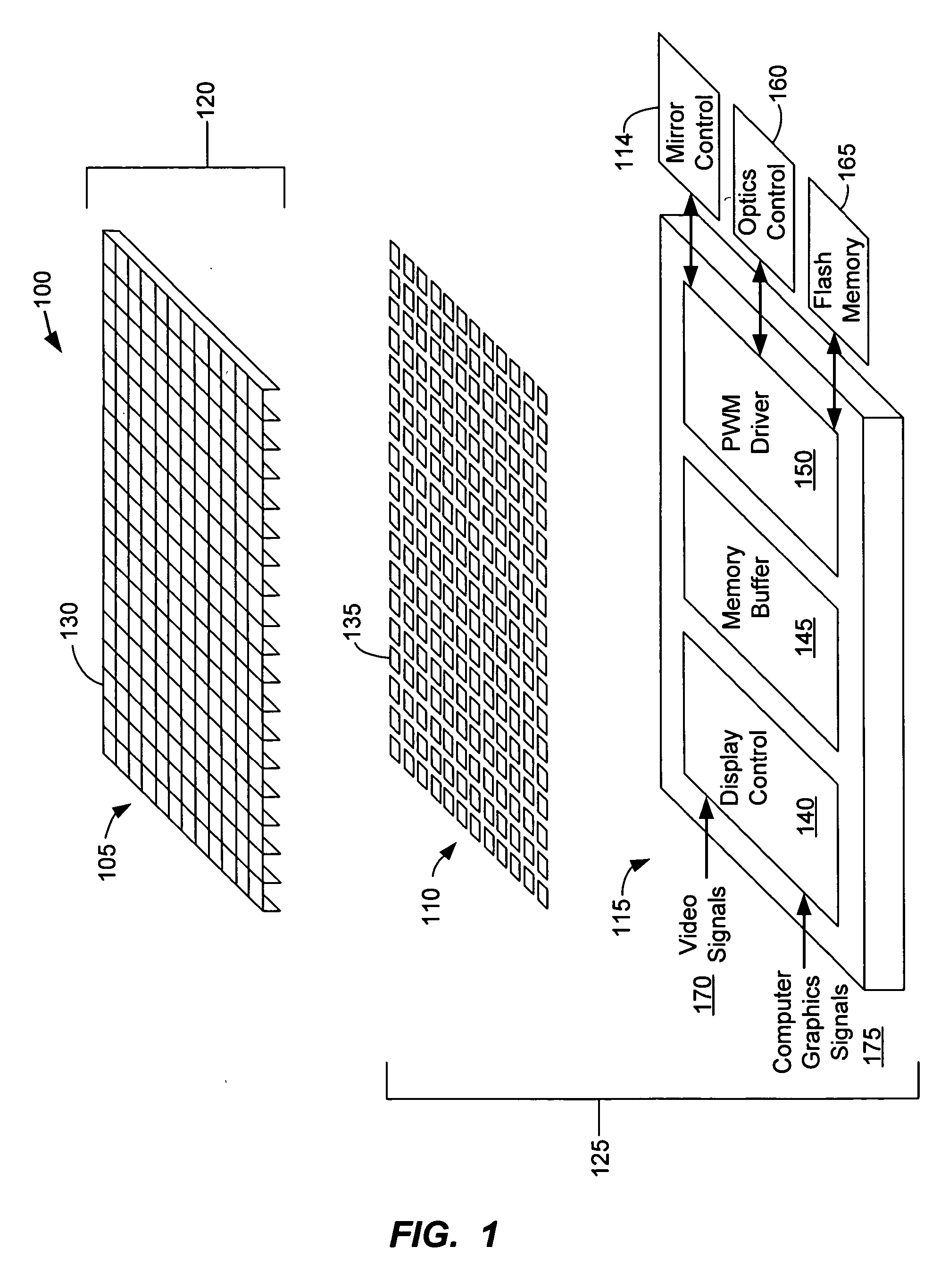

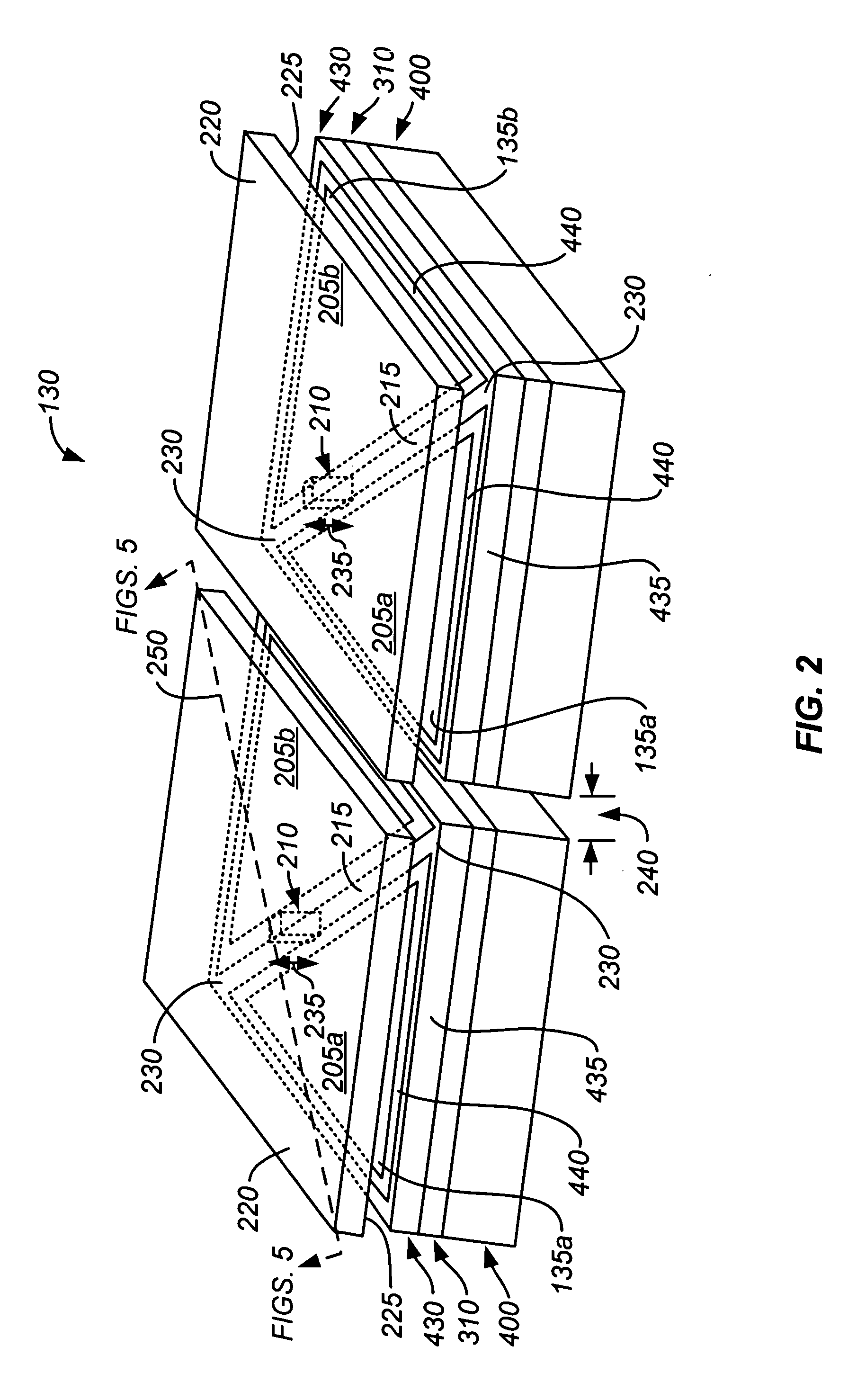

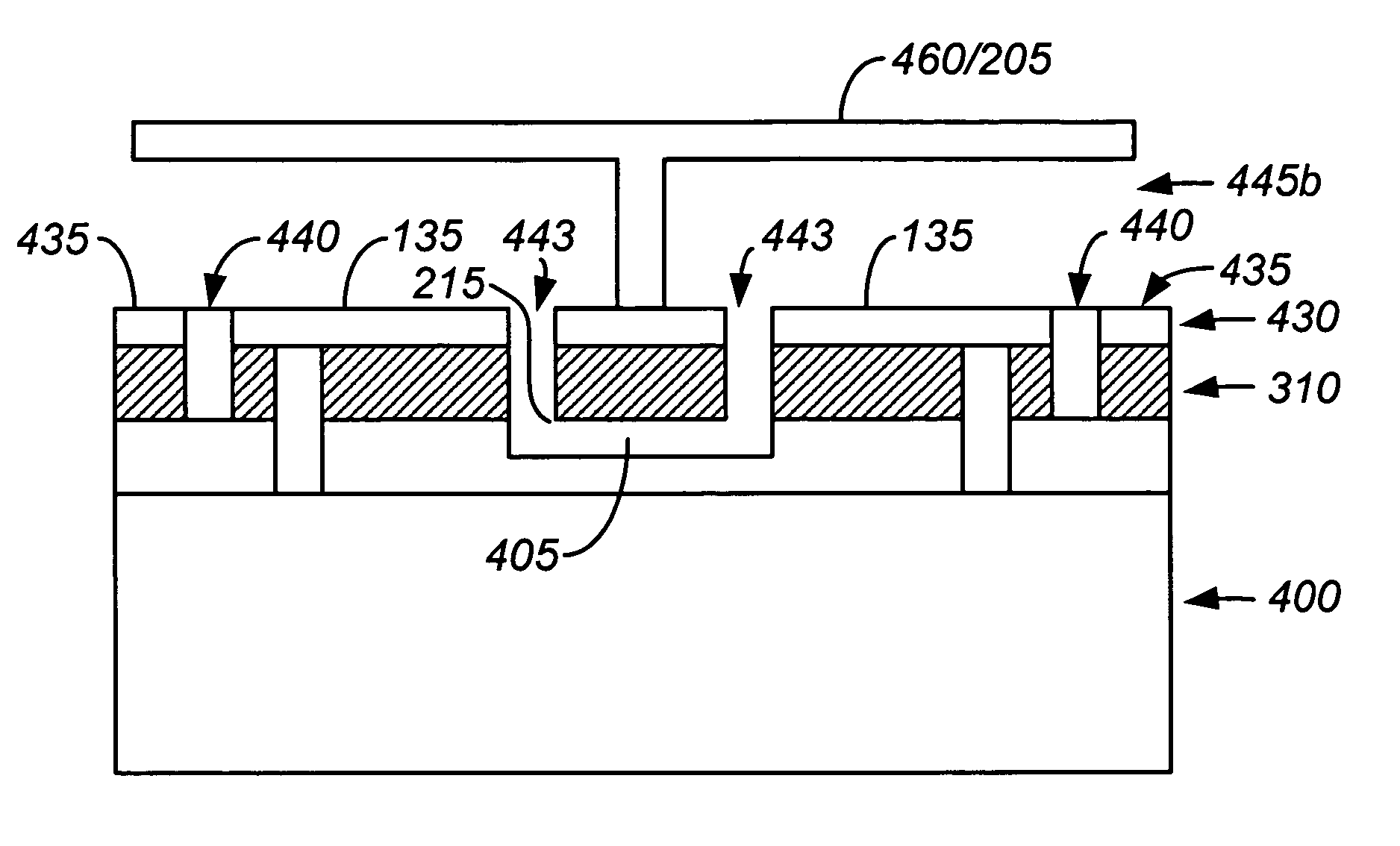

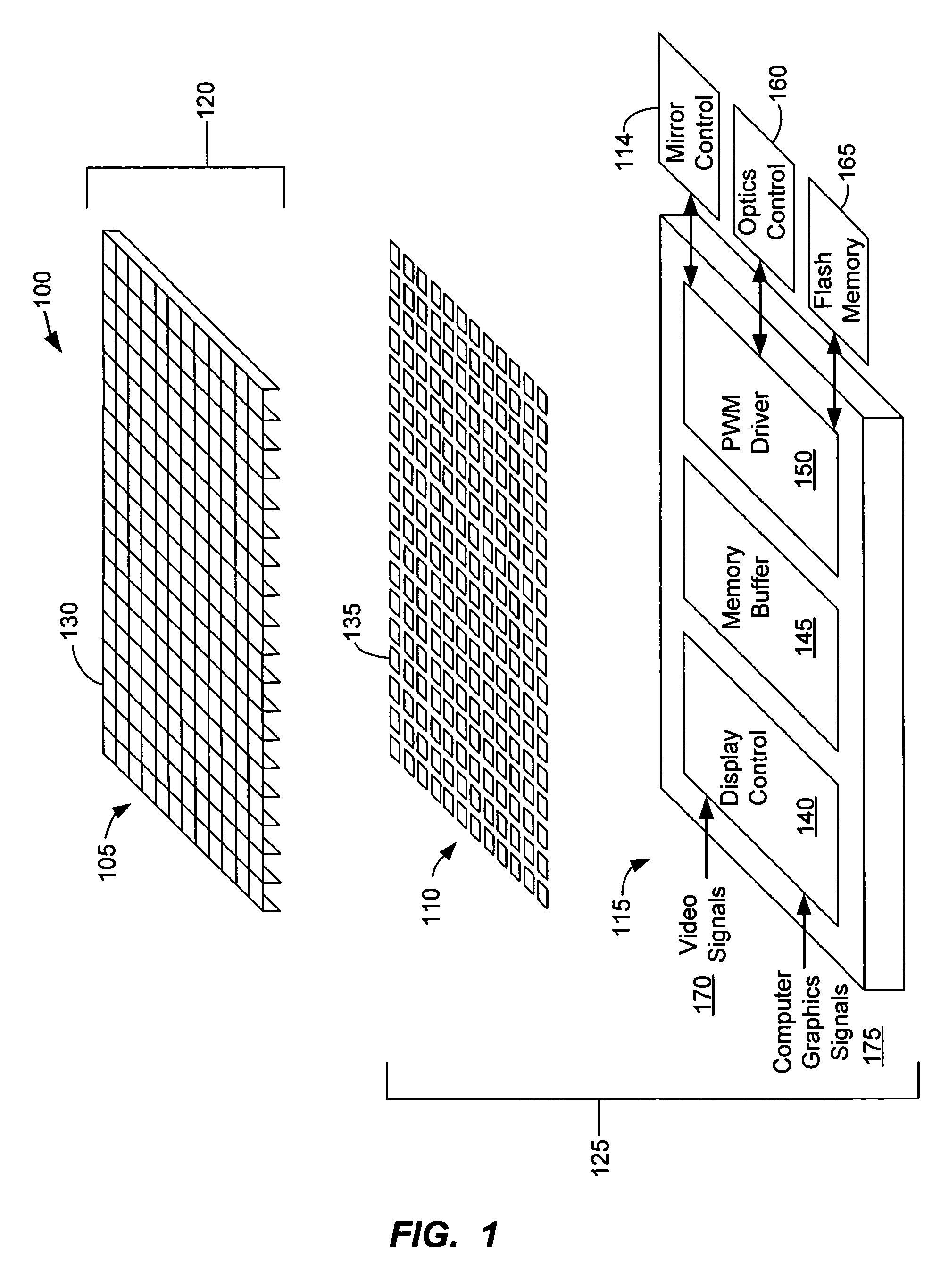

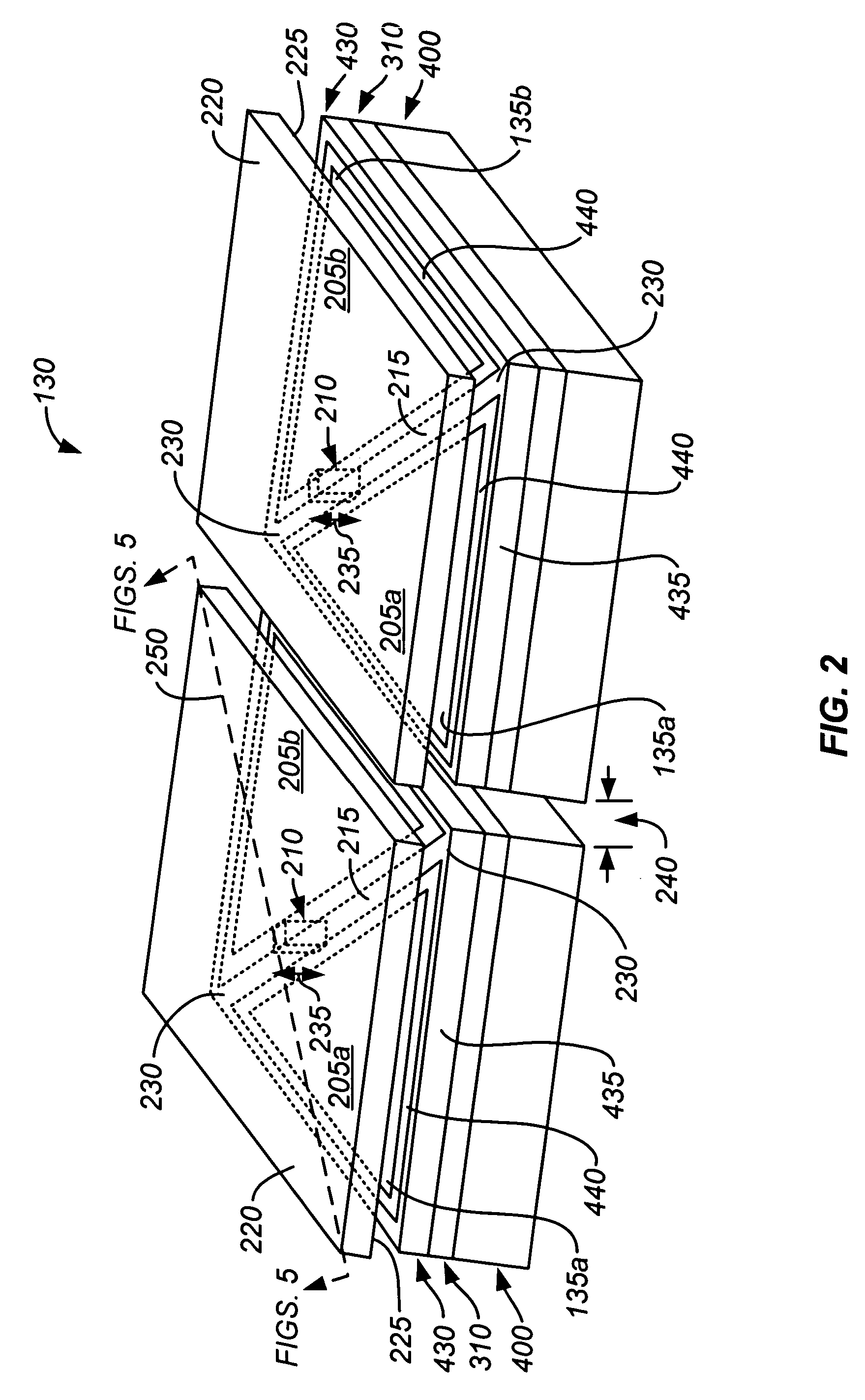

Fabrication of a high fill ratio reflective spatial light modulator with hidden hinge

InactiveUS7034984B2Easy to manufactureImprove optical efficiencySemiconductor/solid-state device manufacturingNon-linear opticsSpatial light modulatorSingle crystal

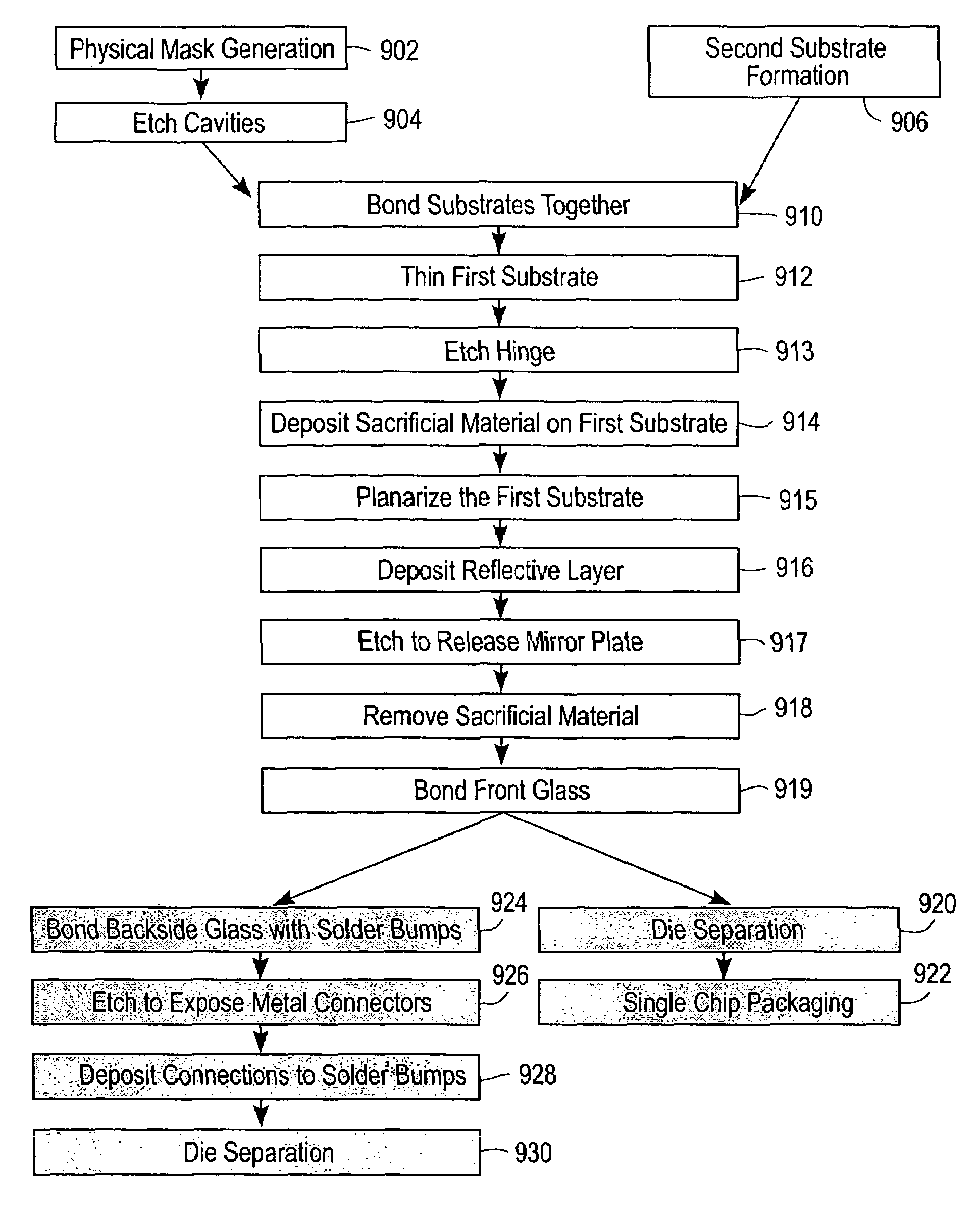

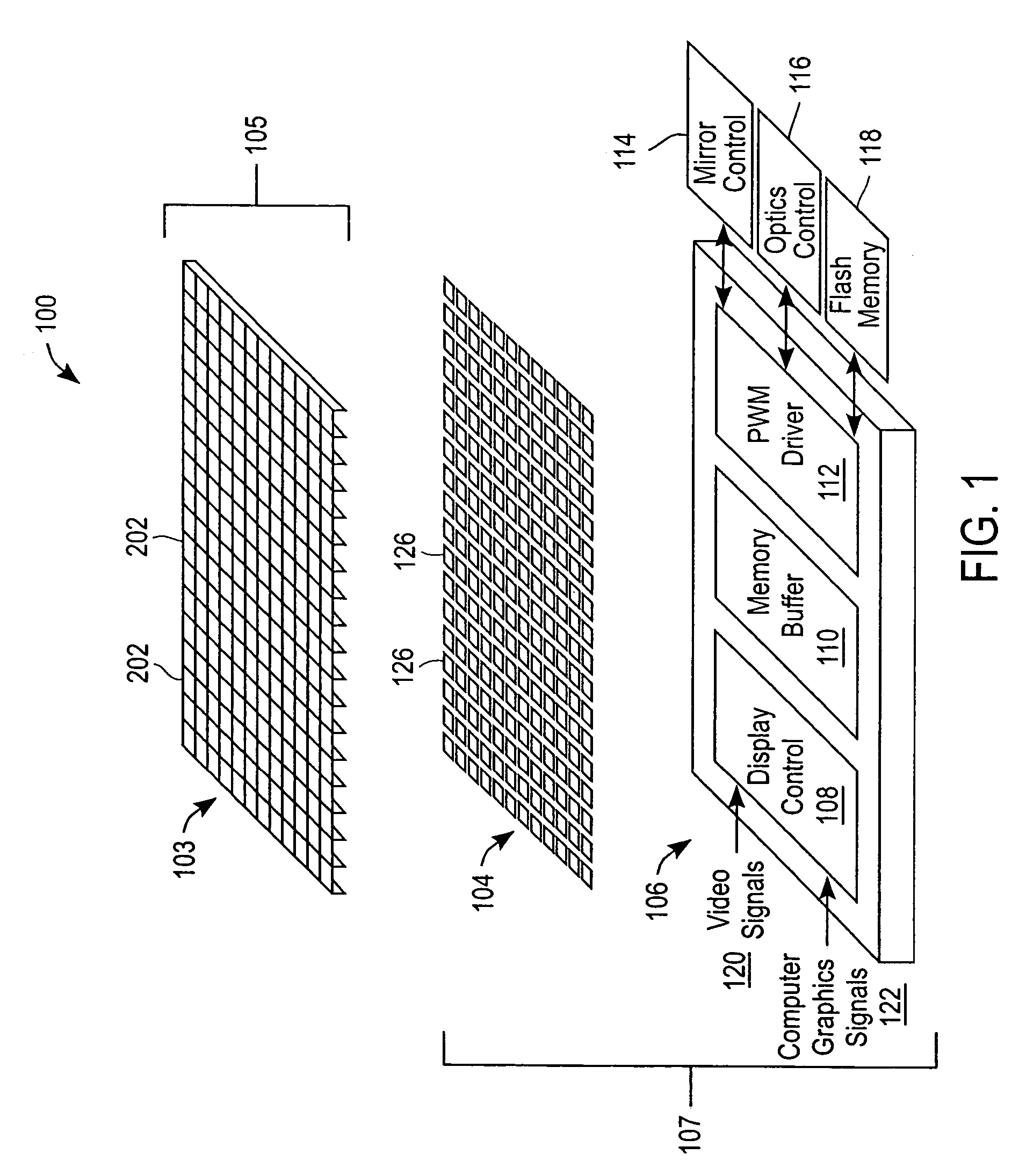

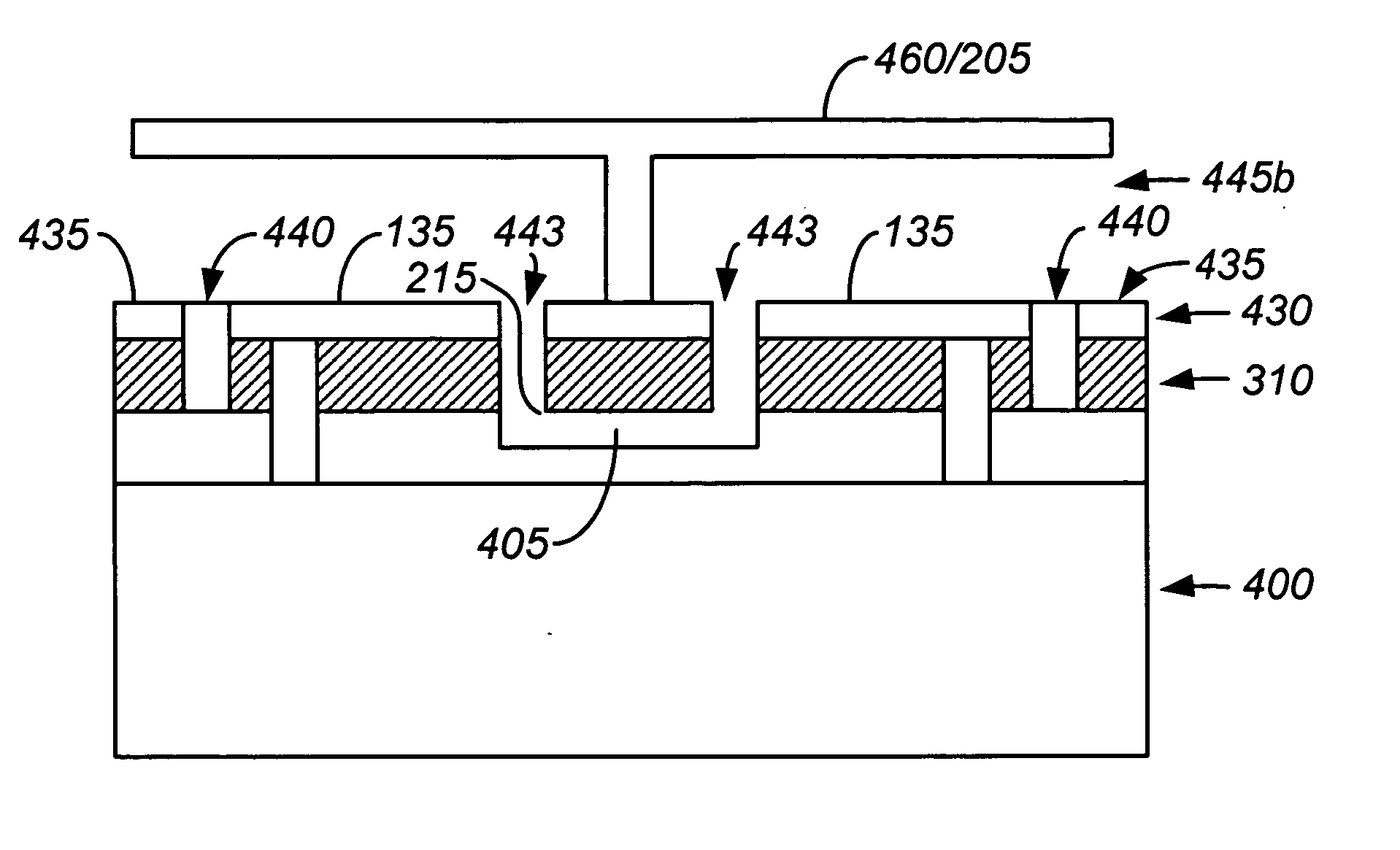

Fabrication of a micro mirror array having a hidden hinge that is useful, for example, in a reflective spatial light modulator. In one embodiment, the micro mirror array is fabricated from a substrate that is a first substrate of a single crystal material. Cavities are formed in a first side of the first substrate. Separately, electrodes and addressing and control circuitry are fabricated on a first side of a second substrate. The first side of the first substrate is bonded to the first side of the second substrate. The sides are aligned so the electrodes on the second substrate are in proper relation with the mirror plates that will be formed on the first substrate and that the electrodes will control. The first substrate is thinned to a pre-determined, desired thickness, a hinge is etched, a sacrificial material is deposited, the upper surface of the first substrate is planarized, a reflective surface is deposited to cover the hinge, a mirror is released by etching and the sacrificial layer around the hinge is removed to release the hinge so the hinge can rotate about an axis in line with the hinge.

Owner:MIRADIA INC

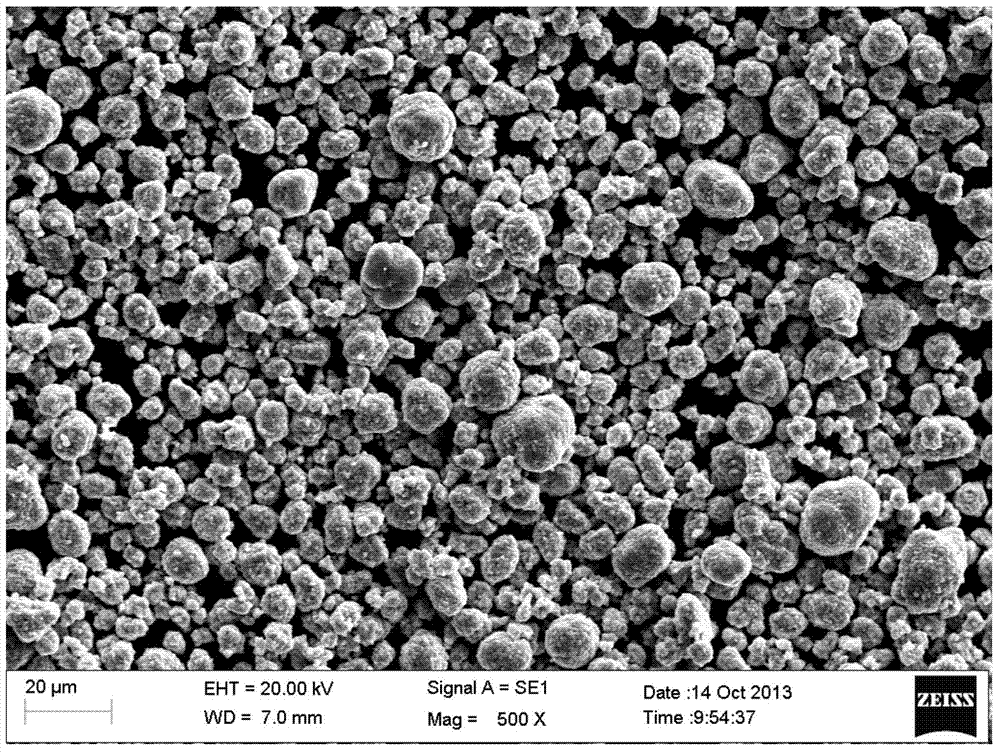

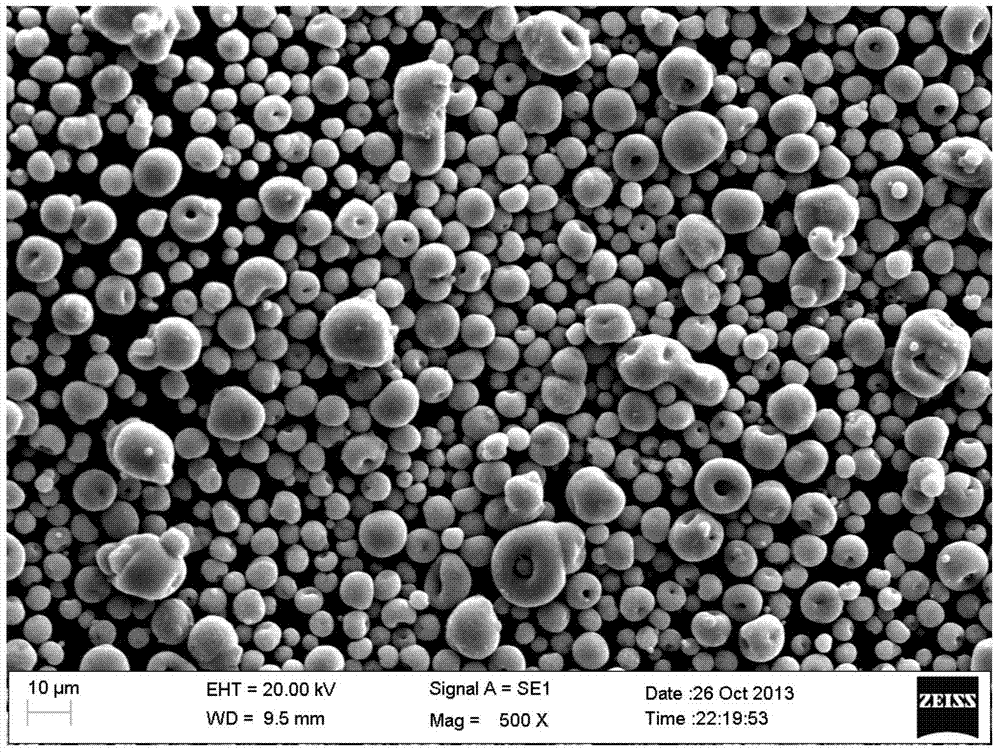

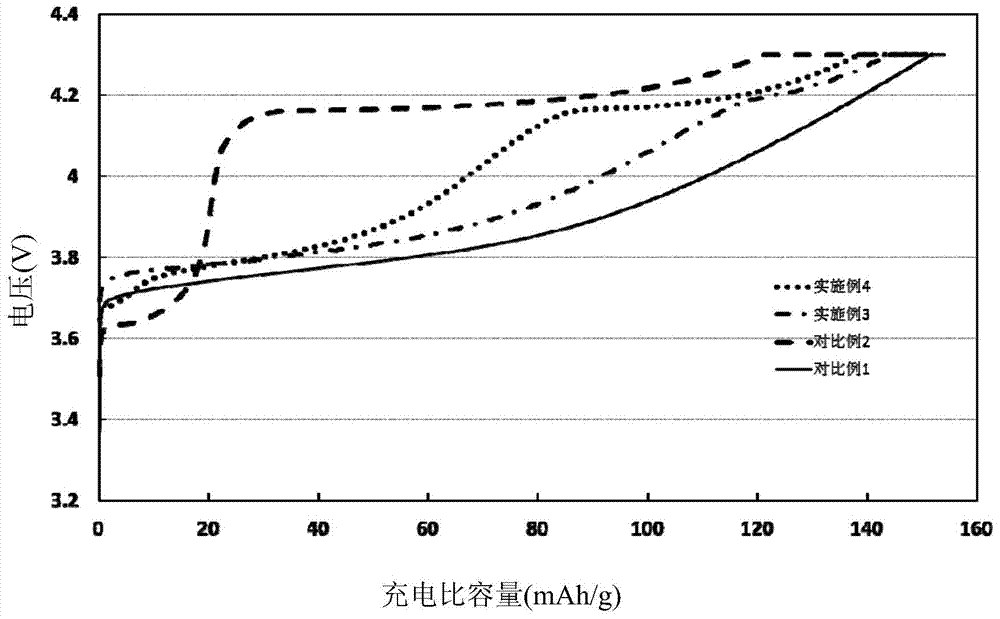

Mixed positive electrode material, positive plate using the same, and lithium ion battery

ActiveCN104300123AIncrease energy densityStable thermal decompositionCell electrodesSecondary cellsHigh energyManganese

The invention discloses a mixed positive electrode material, a positive plate using the same, and a lithium ion battery. The mixed positive electrode material comprises the following component by weight: 50-90 parts of a nickel-cobalt-manganese ternary material and 10-50 parts of lithium-manganese-iron phosphate. The mixed positive electrode material provided by the invention combines the nickel-cobalt-manganese ternary material with high energy density and lithium-manganese-iron phosphate with high safety performance, and plays complementary advantages of nickel-cobalt-manganese and lithium-manganese-iron phosphate, so that comprehensive performances of the positive electrode active material are improved. The positive plate prepared by using the mixed positive electrode material increases the safety performance and cycle performance of the lithium ion battery, increases average voltage of the lithium ion battery, and keeps relatively high energy density; and the lithium ion battery using the positive plate has excellent electrochemical performances, high energy density and high safety performances and long cycle life, and is suitable for popularization and application.

Owner:中创新航科技(江苏)有限公司

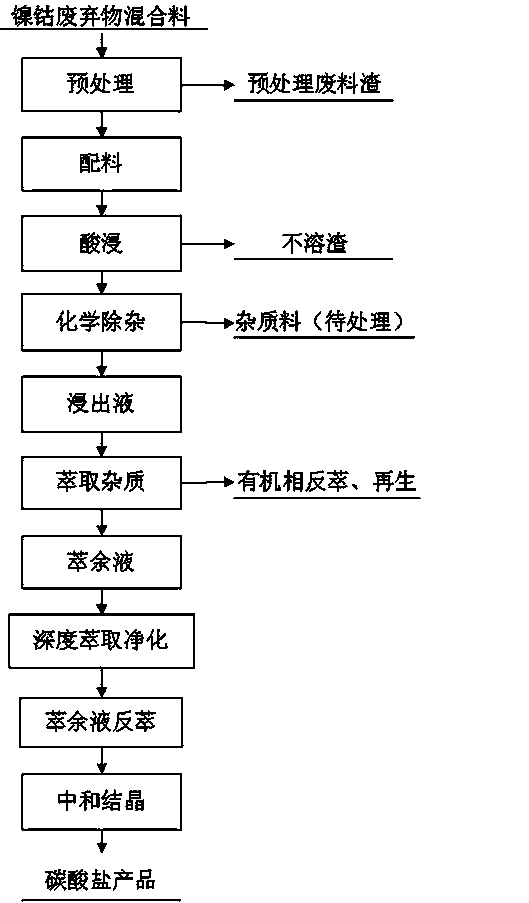

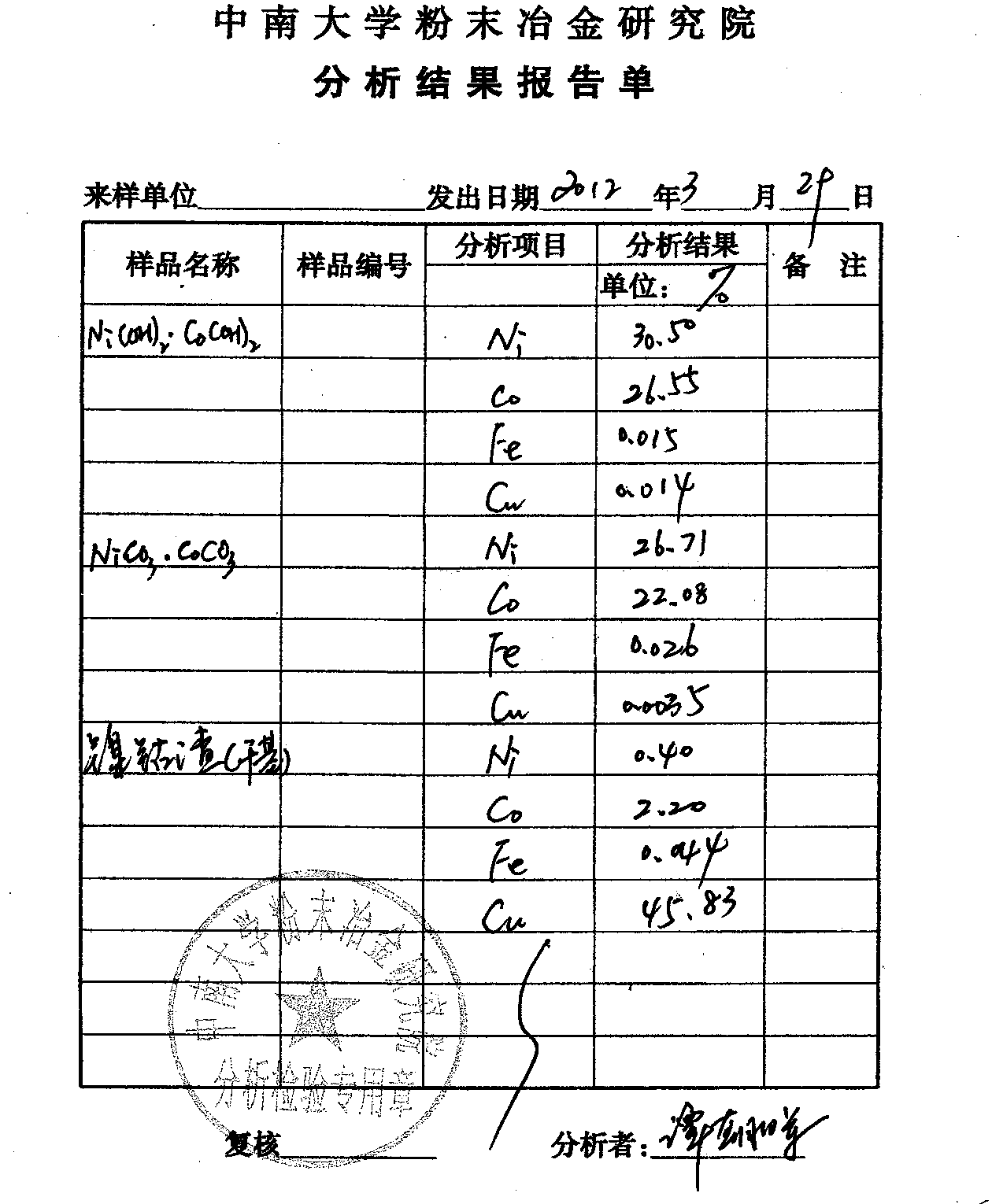

Method for preparing electronic ternary material precursor from Ni-Co residues

ActiveCN103384002AShorten the purification processConducive to hydrometallurgical processCell electrodesEngineeringElectronic materials

The invention discloses a method for preparing an electronic ternary material precursor from Ni-Co residues. The method realizes combination of one or more physical and chemical methods. The method comprises the following steps of pre-treating Ni-Co-containing waste or waste residues so that Ni and Co are preliminarily separated from other substances, adjusting a mole ratio of Ni to Co in the Ni-Co-containing waste or waste residues to 1: (1-0.2), carrying out deep purification of other elements except Ni and Co by an extraction method, treating an Ni-Co group, carrying out separation purification to remove other impurities, wherein Ni and Co is not separated, and directly preparing the Ni-Co oxide precursor of the electronic ternary material by a metallurgical technology, and adding sodium carbonate or sodium hydroxide into a Ni and Co sulfuric acid solution to directly produce an Ni-Co carbonate or an Ni-Co hydroxide. An important characteristic or an innovation point of the method comprises that Ni and Co are combined in an ion level. The method improves environment influence, can produce a novel Ni-Co product and is conducive to resource recycle and environment-friendly development.

Owner:HUNAN KEFEITE HIGH TECH CO LTD

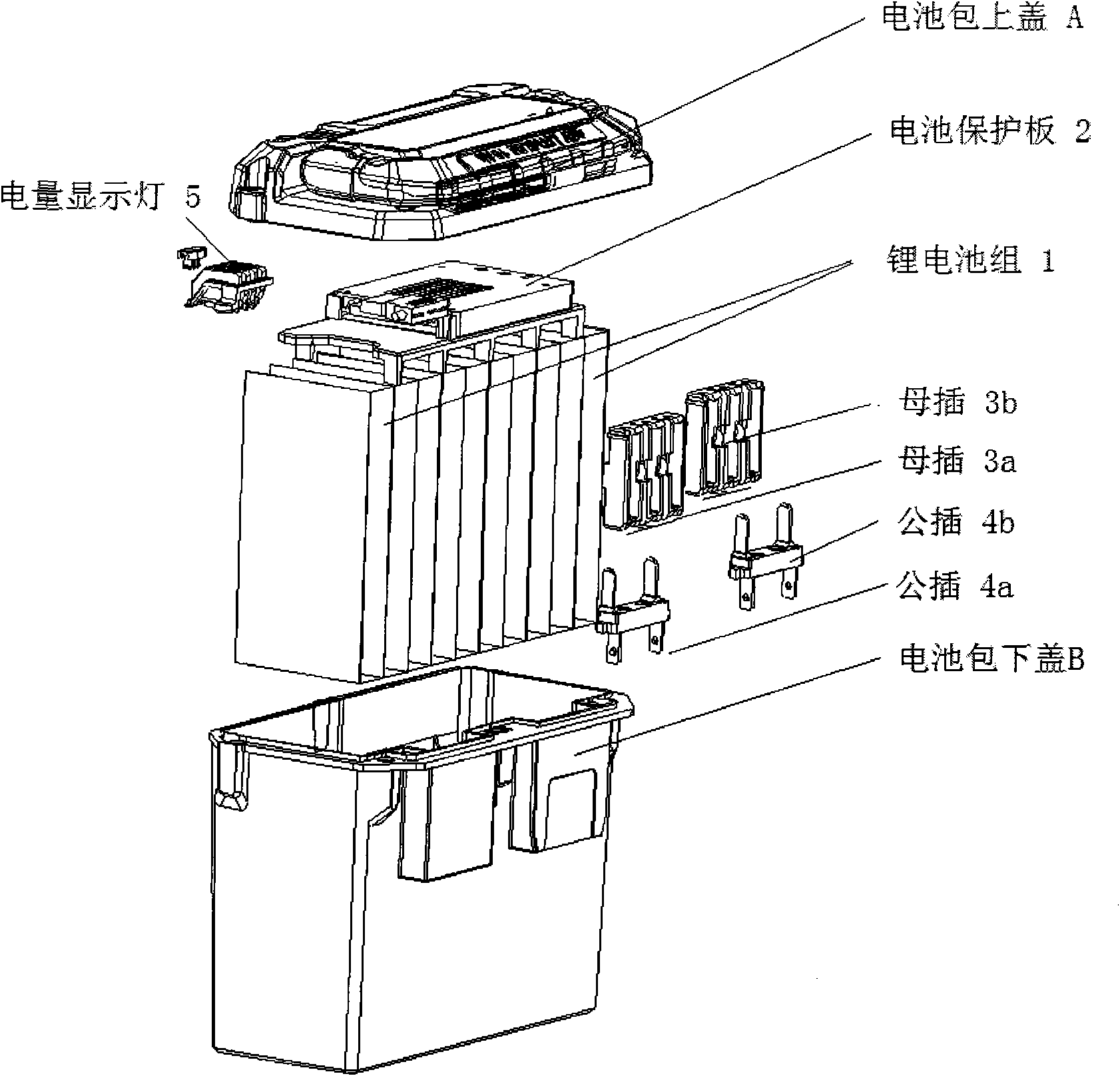

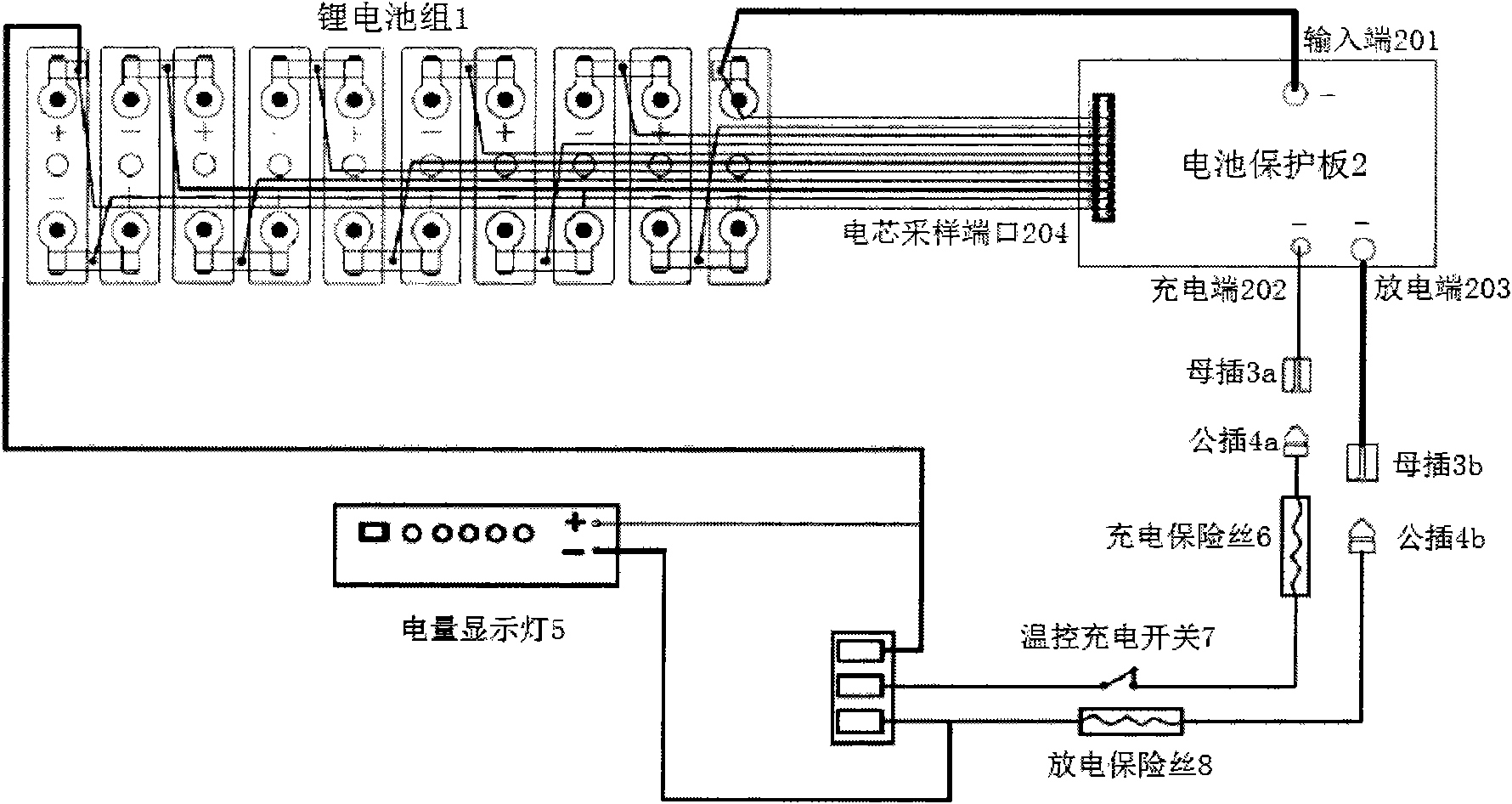

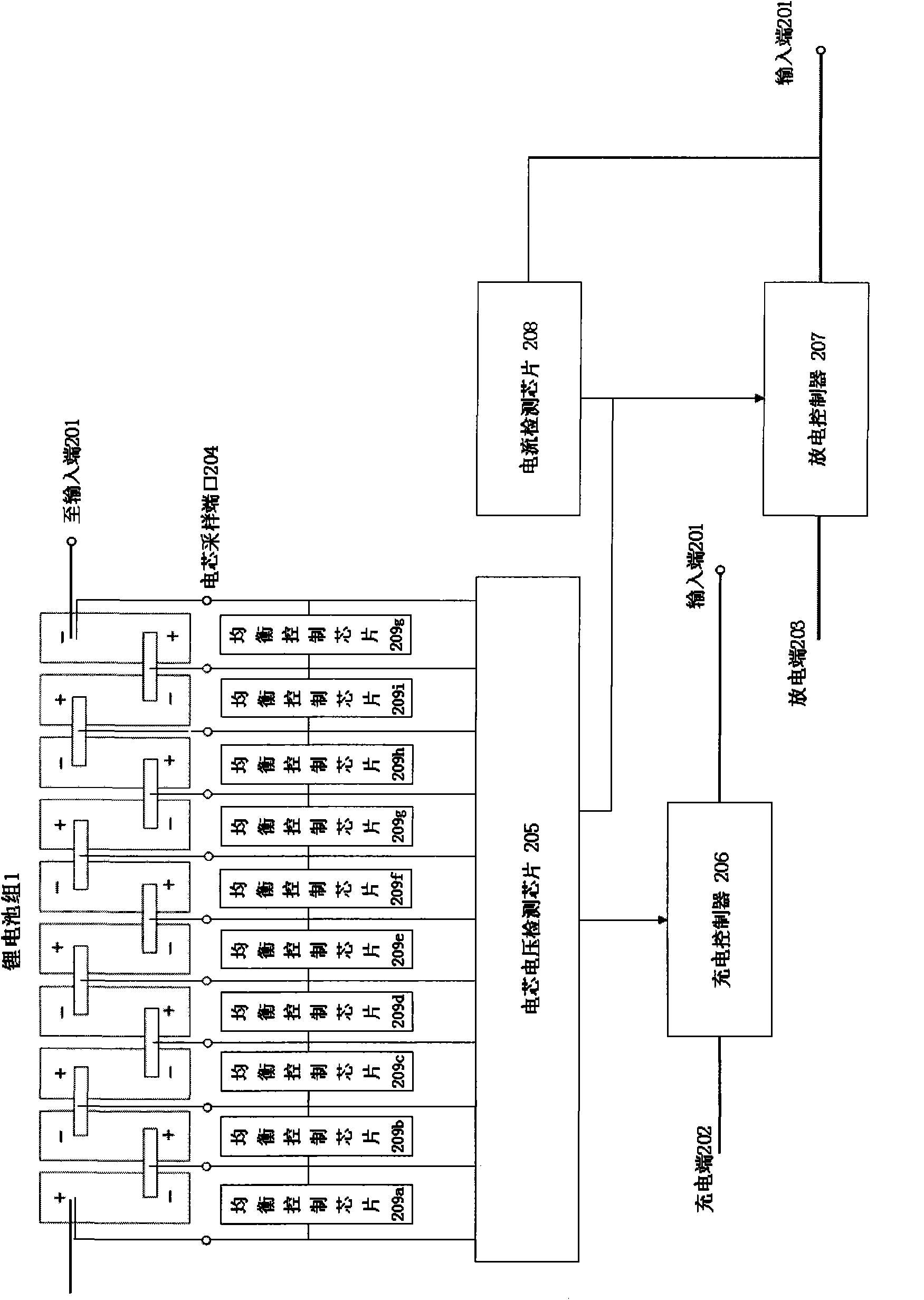

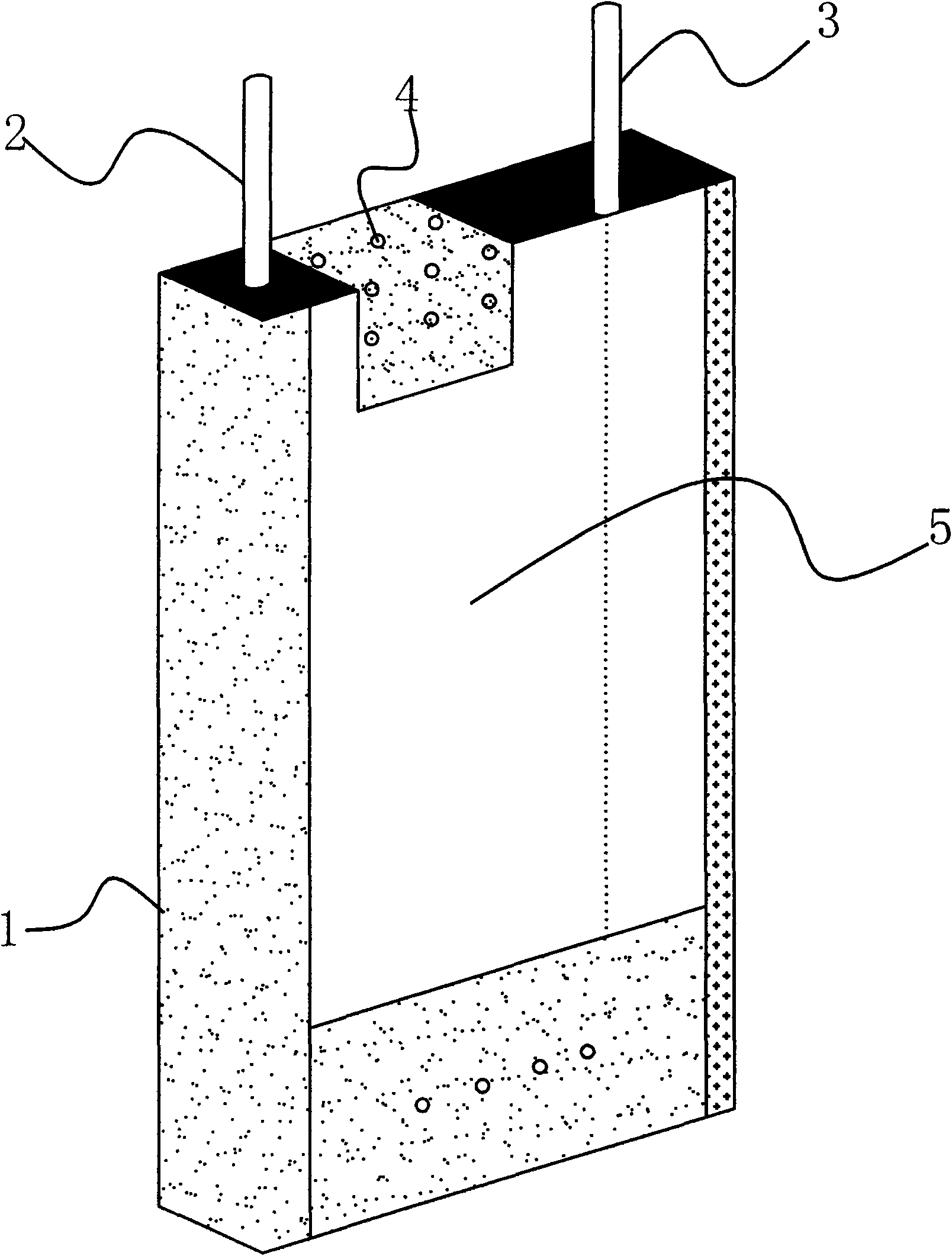

High-capacity lithium battery pack

InactiveCN102208696AReduce volumeImprove cycle lifeBatteries circuit arrangementsElectrical testingHigh energyElectrical battery

The invention relates to a high-capacity lithium battery pack, which is provided with a lithium battery pack (1), a charging interface, a discharging interface, a battery protection plate (2), an electric quantity indicating lamp (5), a charging fuse (6), a temperature control charging switch (7) and a discharging fuse (8), wherein the lithium battery pack (1) is formed by connecting a plurality of single battery cells in series; the charging interface and the discharging interface consist of female plugs (3a, 3b) and male plugs (4a, 4b); and the battery protection plate (2) is used for over charge, over discharge and over current protection and battery cell voltage balance of the lithium battery pack (1). Because the high-capacity lithium battery pack is adopted in the lithium battery pack, the lithium battery pack has the advantages of small volume, light weight, portability, easiness for carrying, high power capacity, high-energy density, high efficiency, high bearing capacity, long cycle life, low self-discharge rate, no memory effect, no pollution, excellent constant-voltage source performance and the like; and through the battery protection plate, adverse conditions of over charge, over discharge, over current, over high voltage of the single battery cells and the like are effectively prevented, the quality of the lithium battery pack is remarkably improved, and the lithium battery pack has the advantages of stable performance and long life.

Owner:CHANGZHOU GLOBE CO LTD

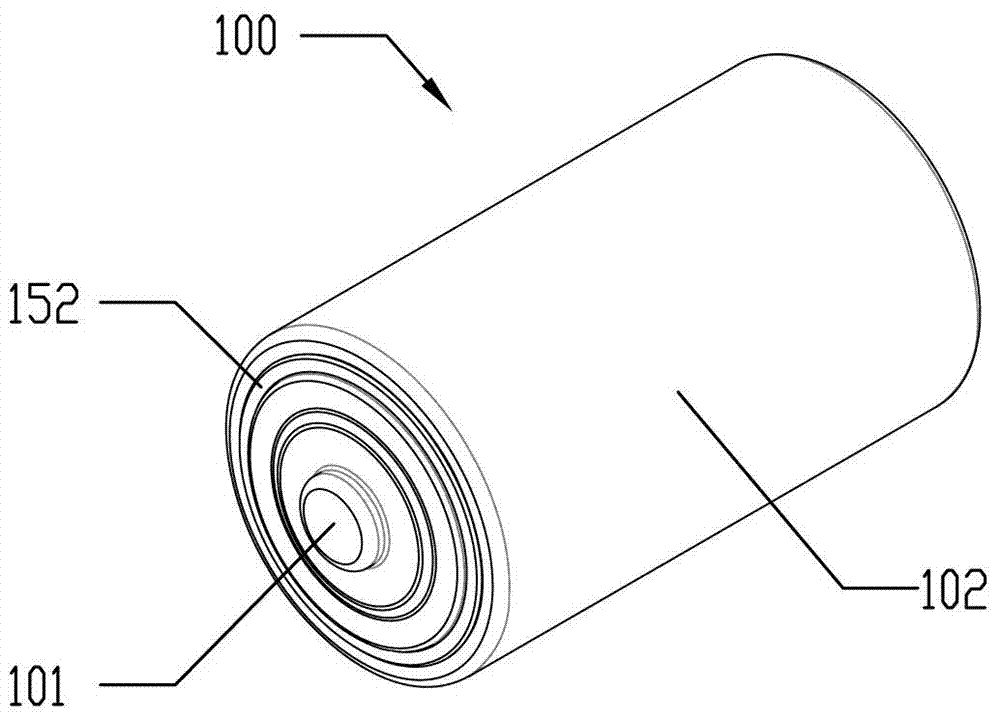

Universal rechargeable battery formed by adopting lithium-ion battery and control method thereof

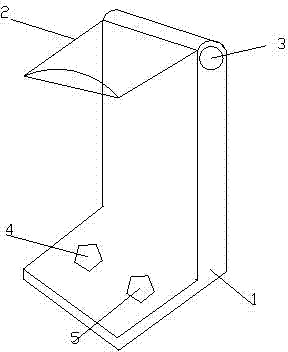

ActiveCN103490112ASimple structure and assembly processConducive to automated mass production assemblyCells structural combinationElectric powerElectrical batteryCommon battery

The invention provides a universal rechargeable battery formed by adopting a lithium-ion battery and a control method thereof. The universal rechargeable battery comprises an external packing casing, as well as a charging / discharging controller, a positive electrode welding piece, the lithium-ion battery and a negative electrode end cover which are sequentially assembled in the external packing casing in a press fit manner, wherein the charging / discharging controller comprises a charging / discharging controller casing as well as a charging / discharging control circuit welding body and a charging / discharging controller support, which are arranged in the charging / discharging controller casing; a lithium-ion battery charging / discharging control circuit is welded on a charging / discharging control circuit welding body; the lithium-ion battery charging / discharging control circuit comprises a lithium-ion battery charging control circuit welded on a circuit board, electrically connected with the lithium-ion battery and the positive electrode end cover respectively and further electrically connected with the negative electrode end cover via the charging / discharging controller casing and the external packing casing, a lithium-ion battery detection and control circuit, and a DC-DC step-down voltage stabilizing discharging circuit.

Owner:SHENZHEN MAIGESONG ELECTRICAL TECH CO LTD

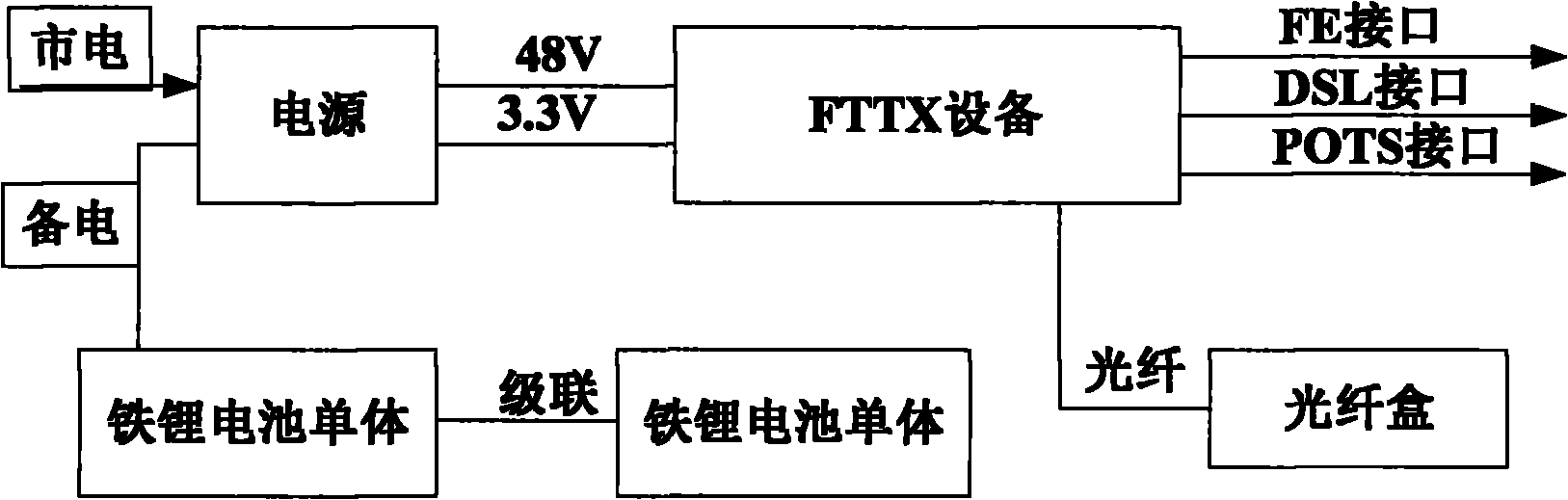

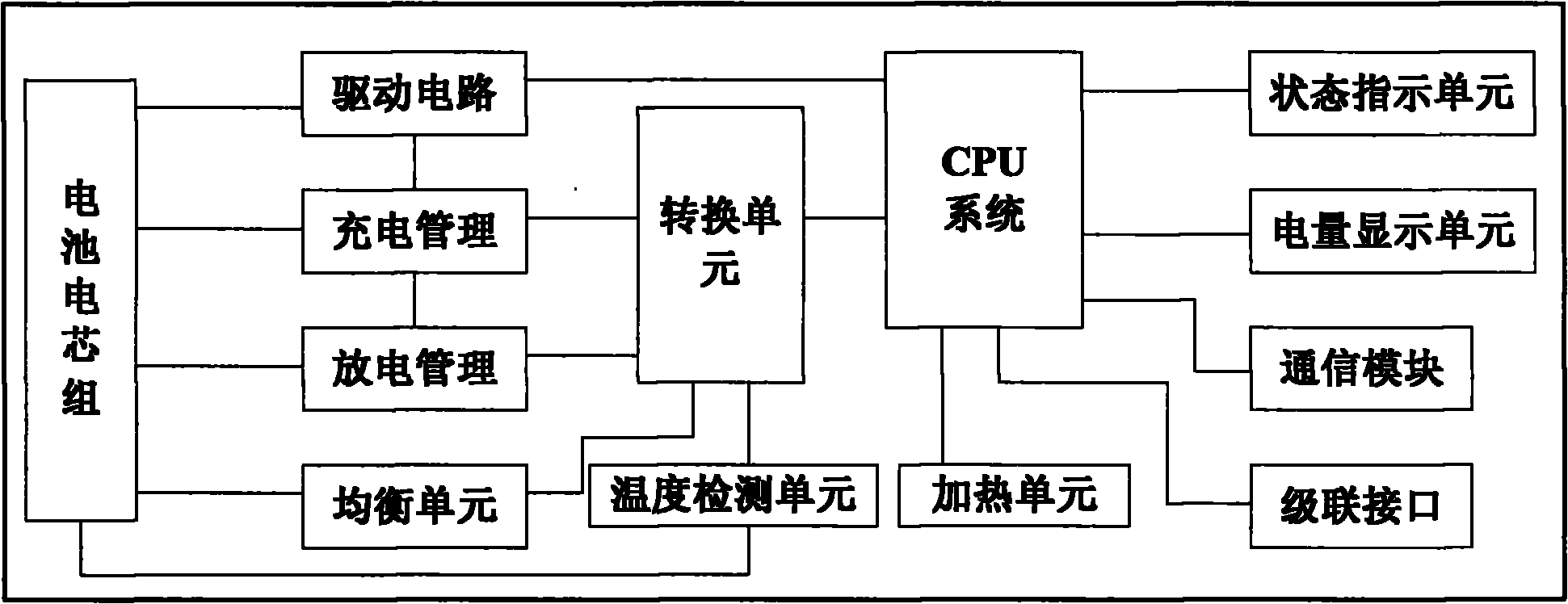

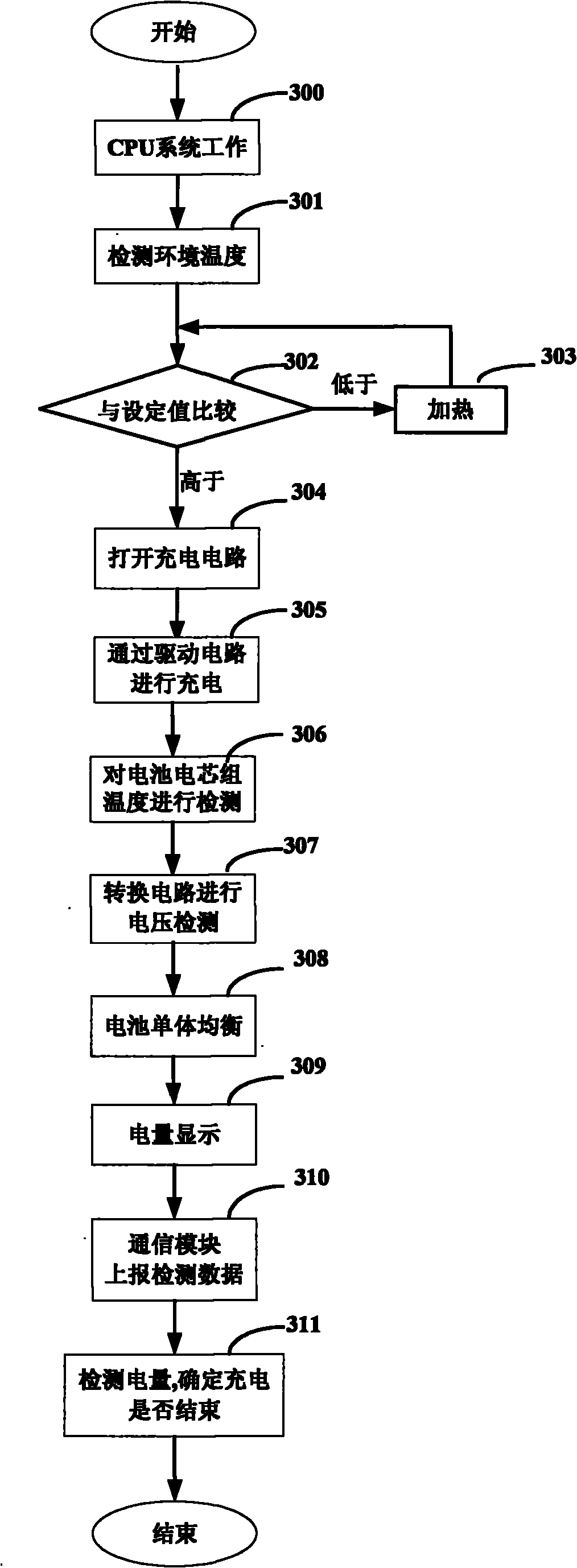

Device and method for storing electricity for fiber access device

ActiveCN101867199AIncrease profitIncrease specific energyBatteries circuit arrangementsEmergency protective circuit arrangementsFiberElectricity

The invention discloses a device and a method for storing electricity for a fiber access device. The device comprises at least a lithium-ferrum battery monomer; the lithium-ferrum battery monomer comprises a battery cell group, a battery control management module and a communication module; the battery cell group comprises a plurality of lithium-ion battery cells which use the anode material as lithium ferrum phosphate and is used for storing electrical energy; the battery control management module is used for controlling the charge / discharge management of the battery cell group and sending the acquired battery-related parameter and the alarm information sent out according to the parameter to the communication module; and the communication module is used for reporting the battery-related parameter and the alarm information sent by the battery control management module to the fiber access device. The device and the method have the characteristics of small volume, light weight, long cycle life, relatively deep discharge depth and no memory effect, toxin or pollution, thereby ensuring the safety and stability of the use of the fiber access device.

Owner:ZTE CORP

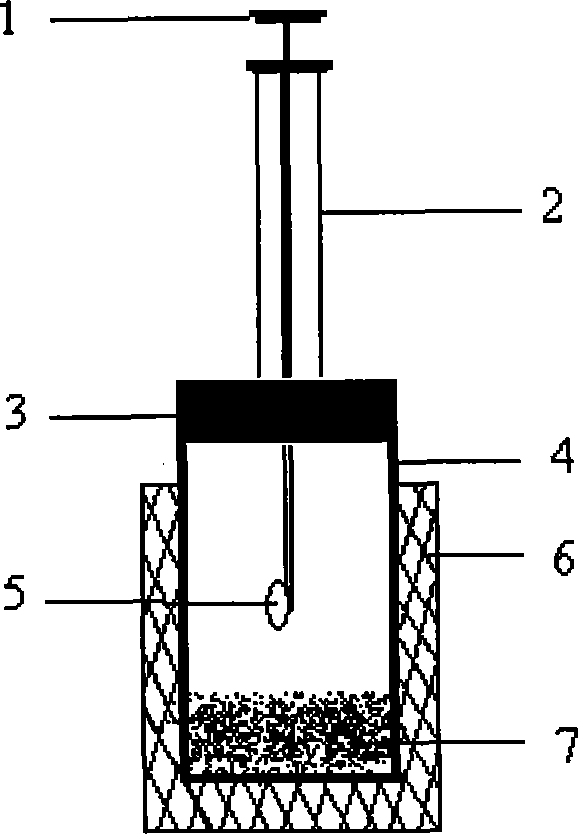

Sample top cavity syringe needle tip deriving method and its uses

InactiveCN101144800ANo memory effectReduce dosageComponent separationPreparing sample for investigationFluid phaseAnalyte

The present invention provides a derivatization method and the application thereof of a sample based on the needlepoint in a top empty bottle, and includes the following procedures: 1, using a minim injector to suck the derivatization reagent and insert the needlepoint into the empty top of a top empty battle in which the sample is preset. 2, making the derivatization reagent form a liquid drop hanging on the needlepoint of the injector and exposes in the empty top of the sample. 3, after a period of derivatization, sucking back the derivatization reagent, and the derivatization process is finished. 4, taking the injector out conducts analysis by instruments directly according to requirements. The derivatization method can be applied in top air of the tobacco sample, or acid ingredient in cigarette smoke and the derivatization of aldehyde ketone ingredient. The present invention has the advantages of simple operation, high efficient derivatization, and lower cost; a trace of derivatization reagent can meet the derivatization purpose of the analysis requirements without memory effect and discrimination effect of the analyzed object. Simultaneously, the present invention combines the liquid phase extraction technology and the derivatization means, improves the sensitivity by the enrichment function of the liquid phase extraction, reduces the dosage of the extraction solvent, and shortens the preparation time.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

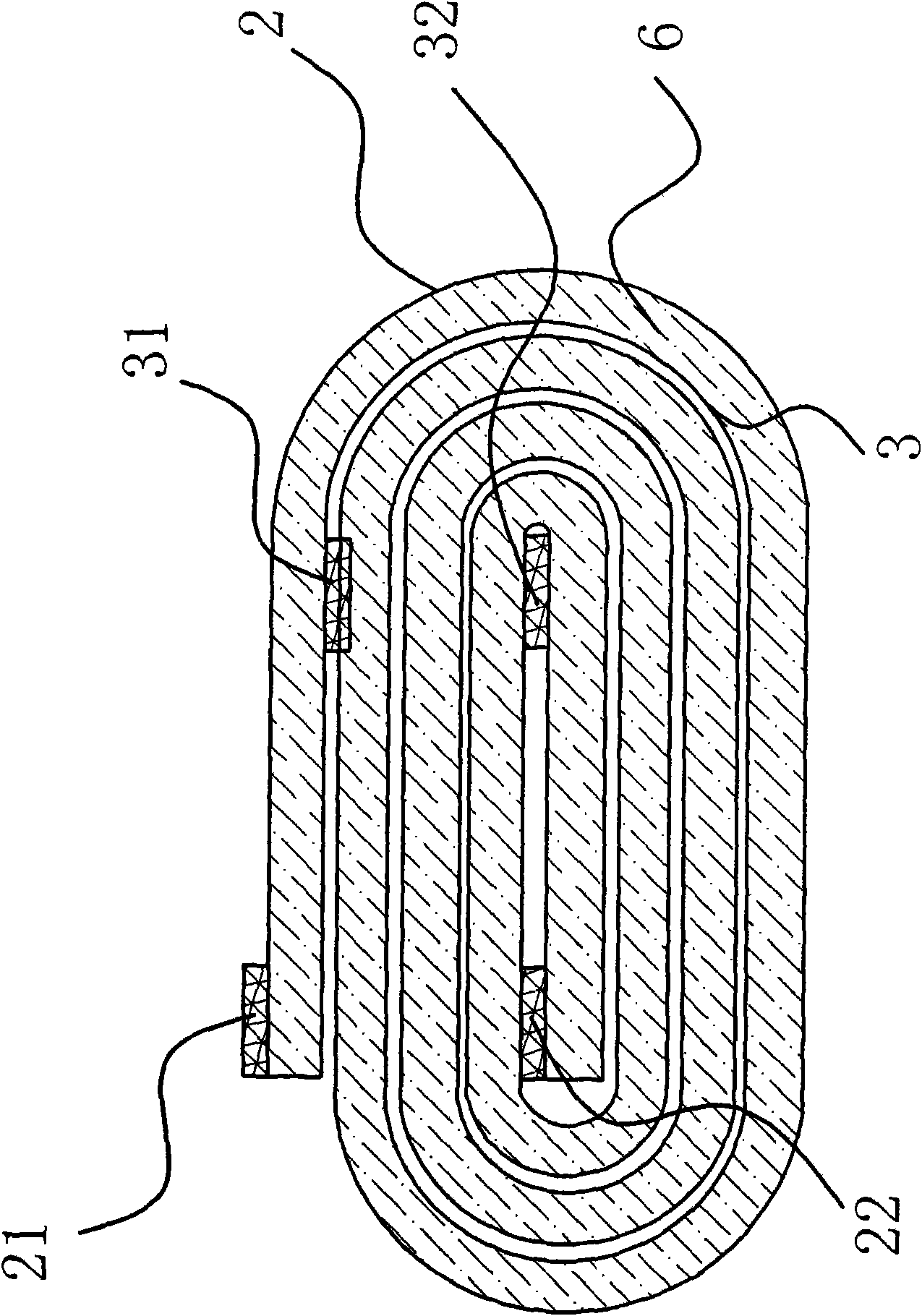

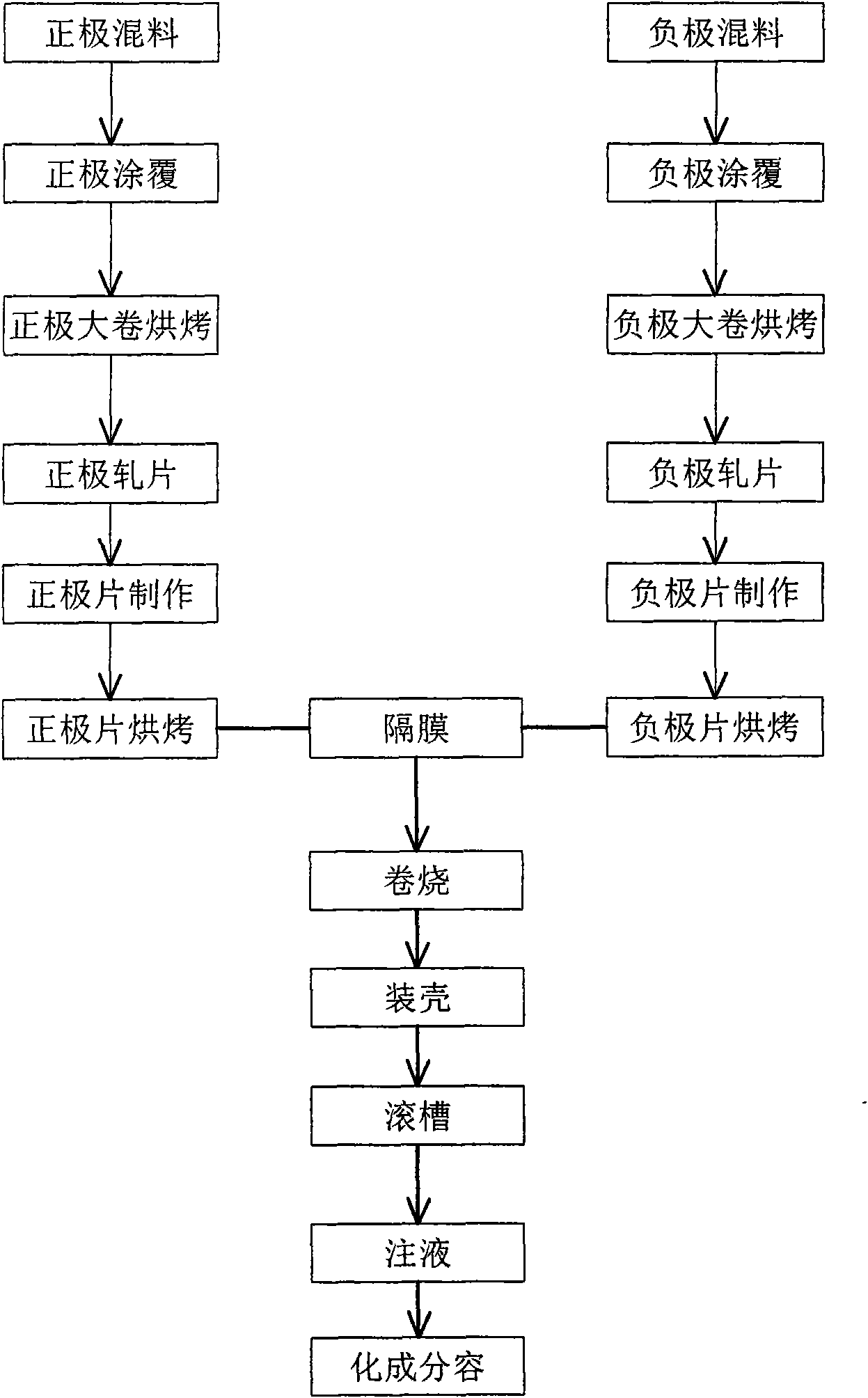

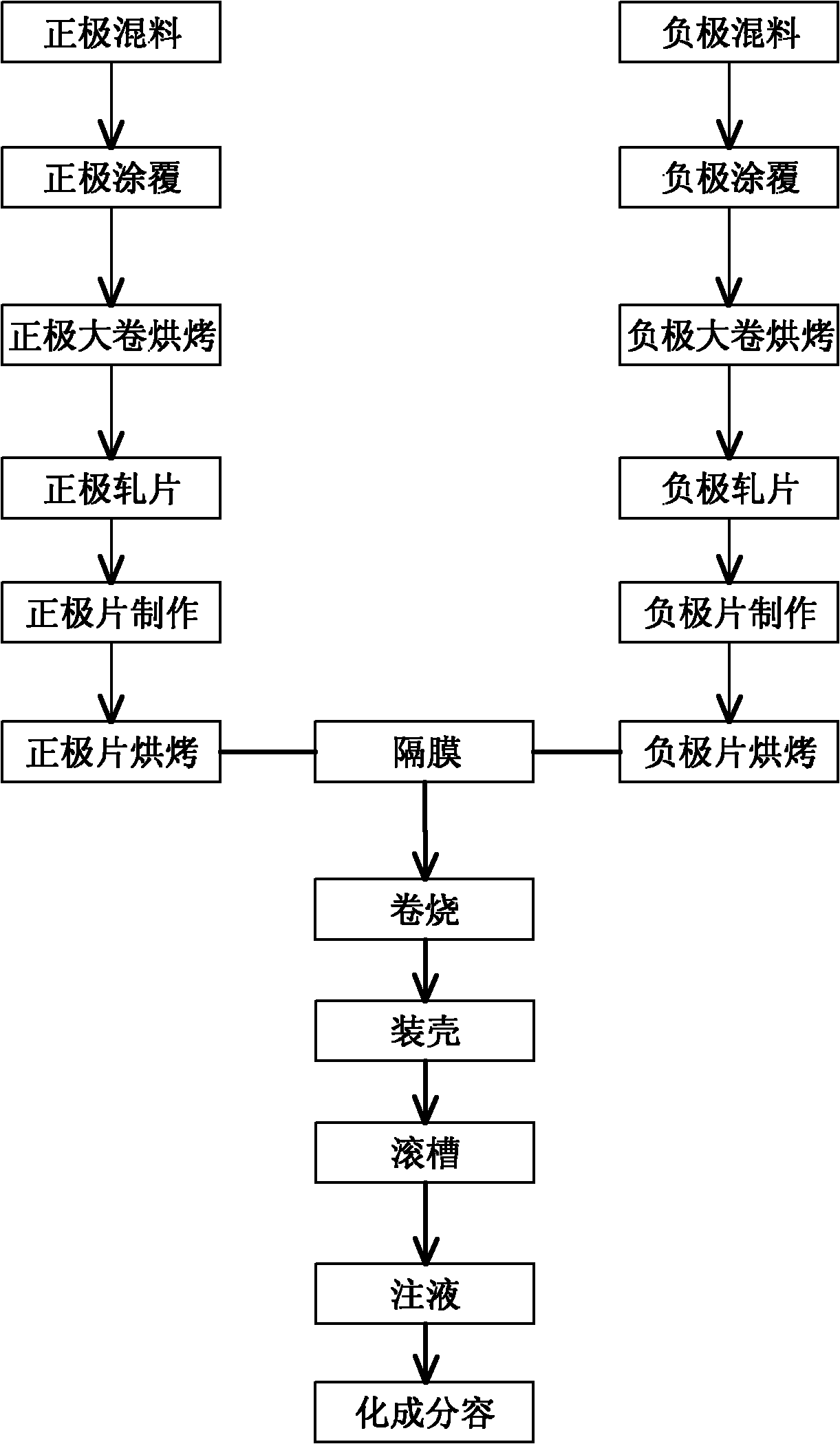

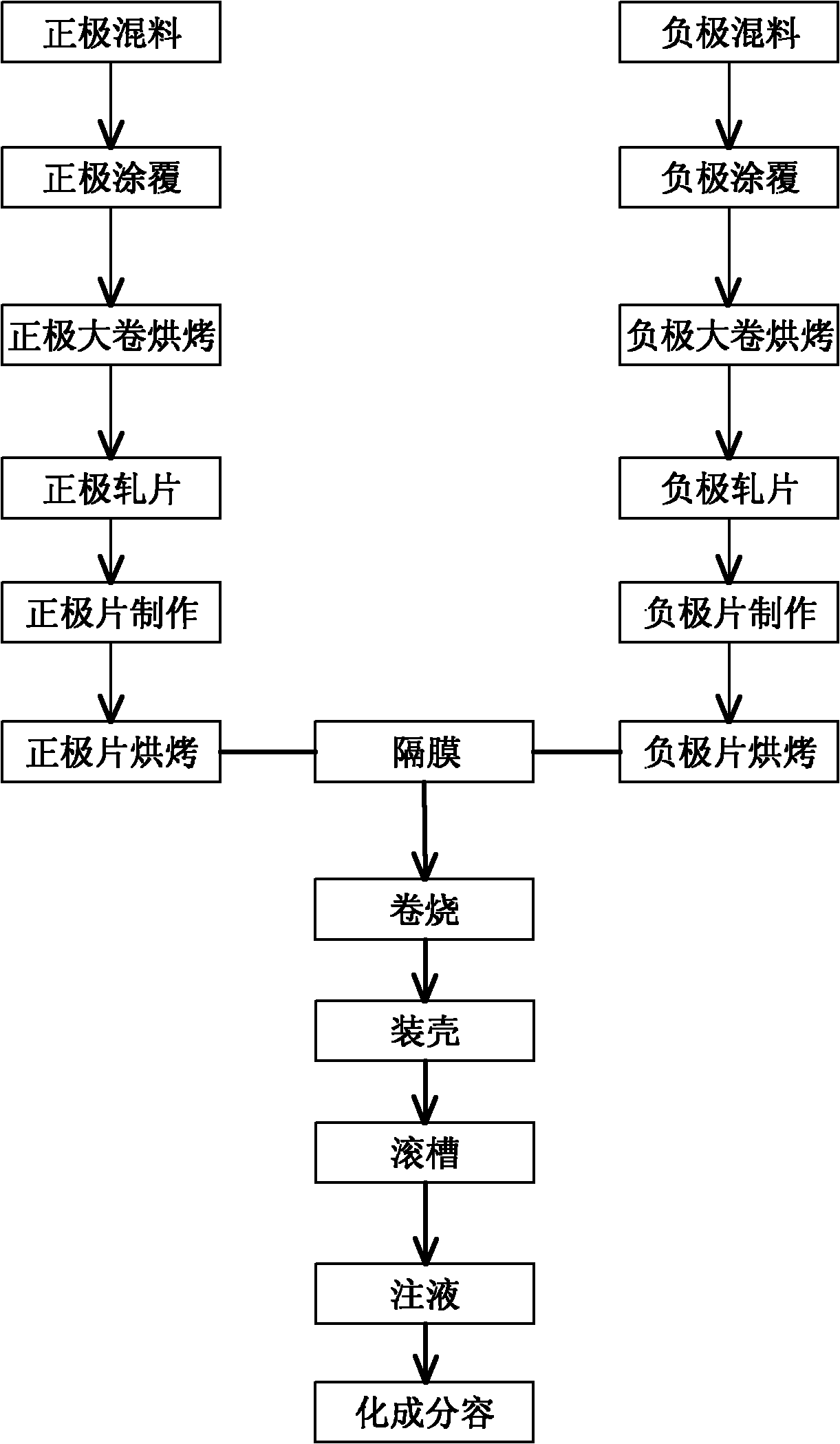

High performance lithium ion secondary battery and manufacture method

InactiveCN101145610ALong cycle lifeLow self-discharge rateElectrode manufacturing processesSecondary cellsWater soluble polymersSolvent

The invention discloses a high-performance lithium ion secondary battery. The active substance of the anode of the battery is lithium-containing compound oxide of the chemical formula: LiFe(1-y)MyPO4, wherein M is one element selected from Co, Ni, Mn, Al, S, Ca, K, Na, Mo and Cr, y is more than 0 but less than or equal to 0.75. A water-soluble polymer is used as an adhesive. The anode of the inventive lithium ion secondary battery is prepared by mixing LiFe(1-y)MyPO4 compound with the water-soluble polymer at a given weight ratio, adding a conductive substrate and water as an solvent, mixing, stirring and filtering to obtain a homogenous slurry, coating the flurry on the surface of an aluminum foil, drying at 55-150 DEG C to obtain an anode piece, winding together with a cathode piece, assembling, infusing, standing, pre-charging with a 0.01C-0.65C current, standing again, and fractioning volumes. The inventive high-performance lithium ion secondary battery has the advantages of good property of high-current charge and discharge, long cycle life, high safety, environmental friendliness, and low cost.

Owner:SHENZHEN YILI ENERGY

Mirror structure with single crystal silicon cross-member

Hydrogen cleave silicon process for light modulating mirror structure using single crystal silicon as the base cross-member. Existing processes use two critical alignment steps that can contribute to higher actuation voltages and result in lower manufacturing yields. The hydrogen cleave process simplifies the manufacturing process to one step: transferring a thin film of single crystal silicon to the CMOS substrate, resulting in minimal alignment error and providing large bonding area.

Owner:MIRADIA INC

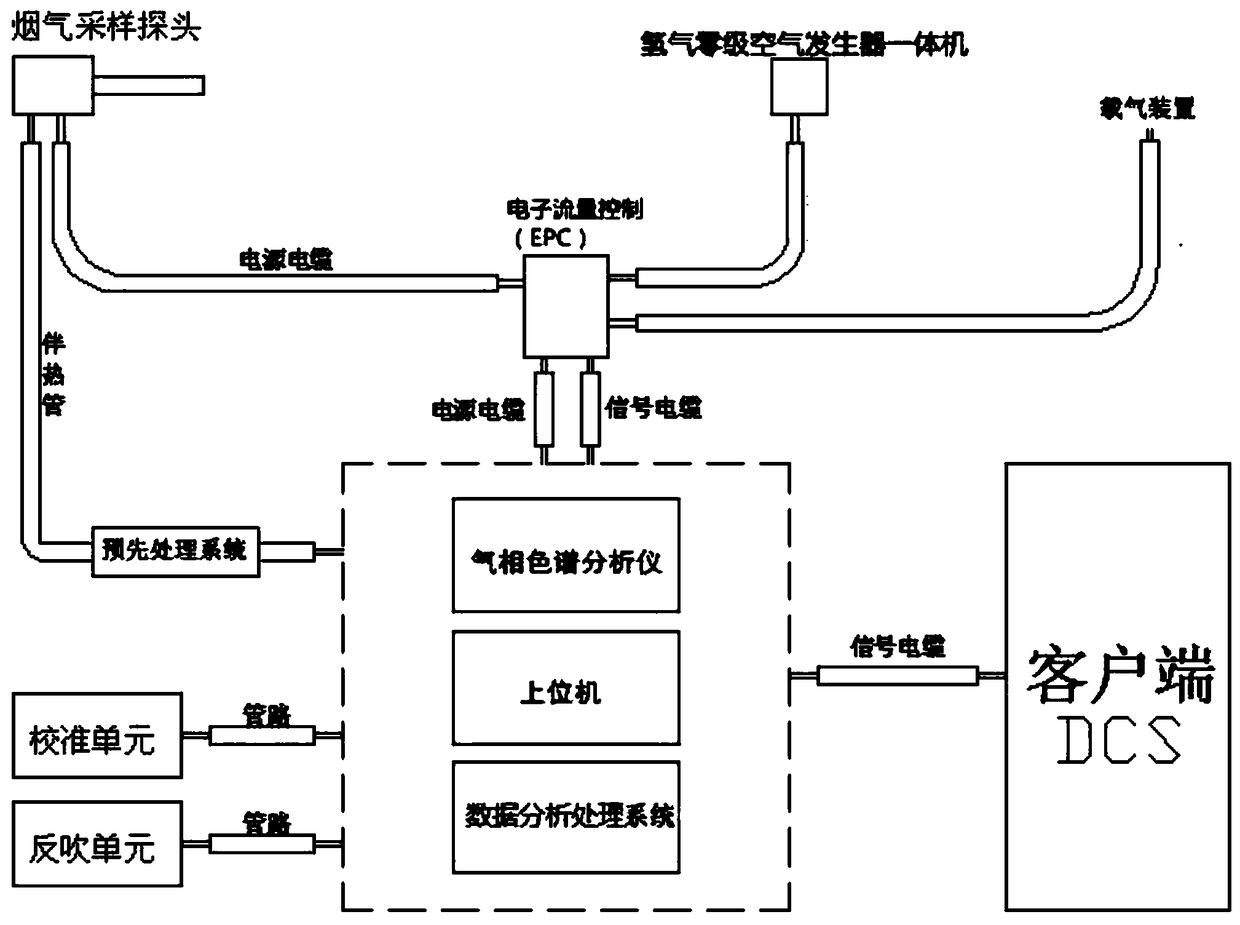

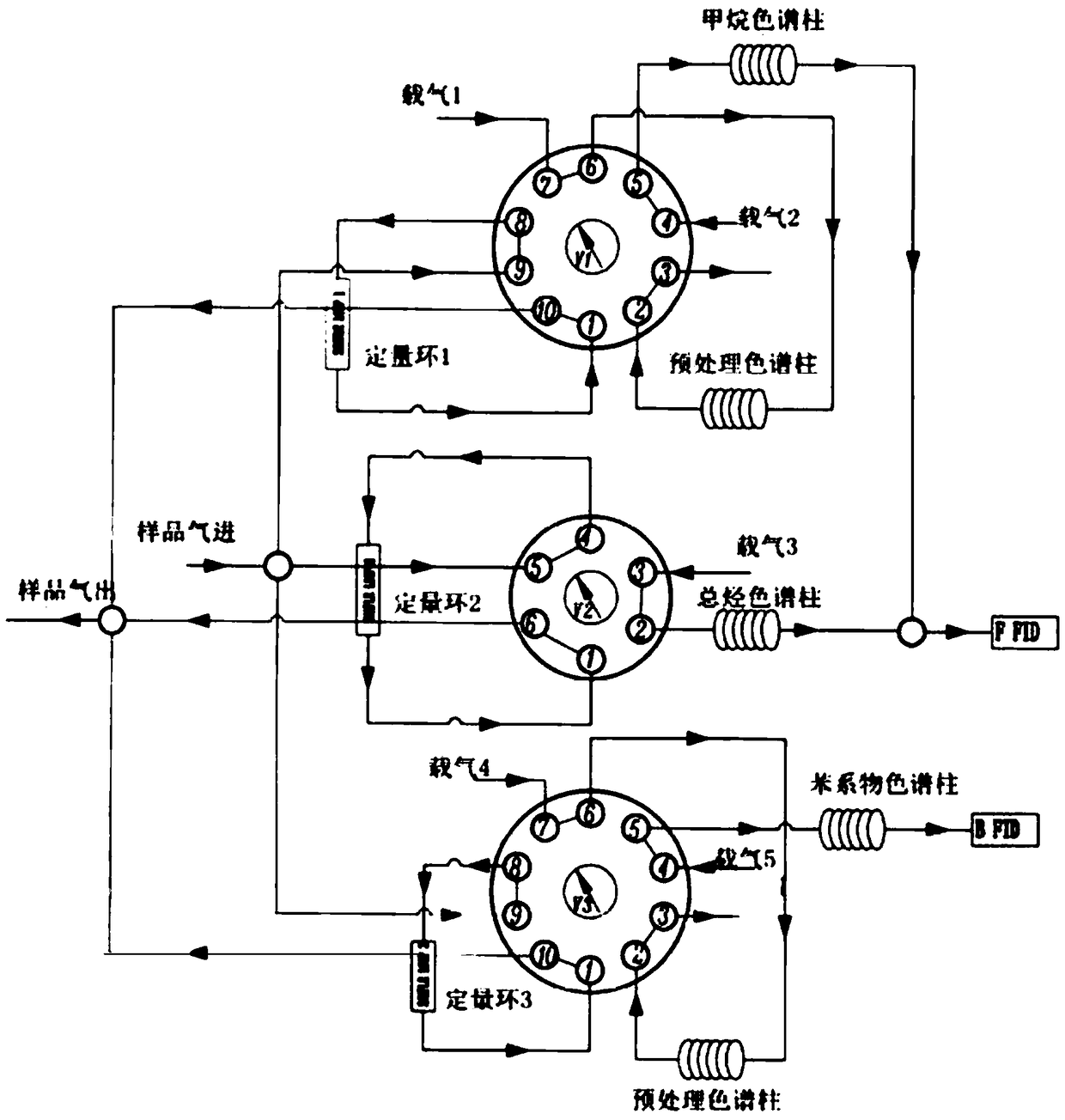

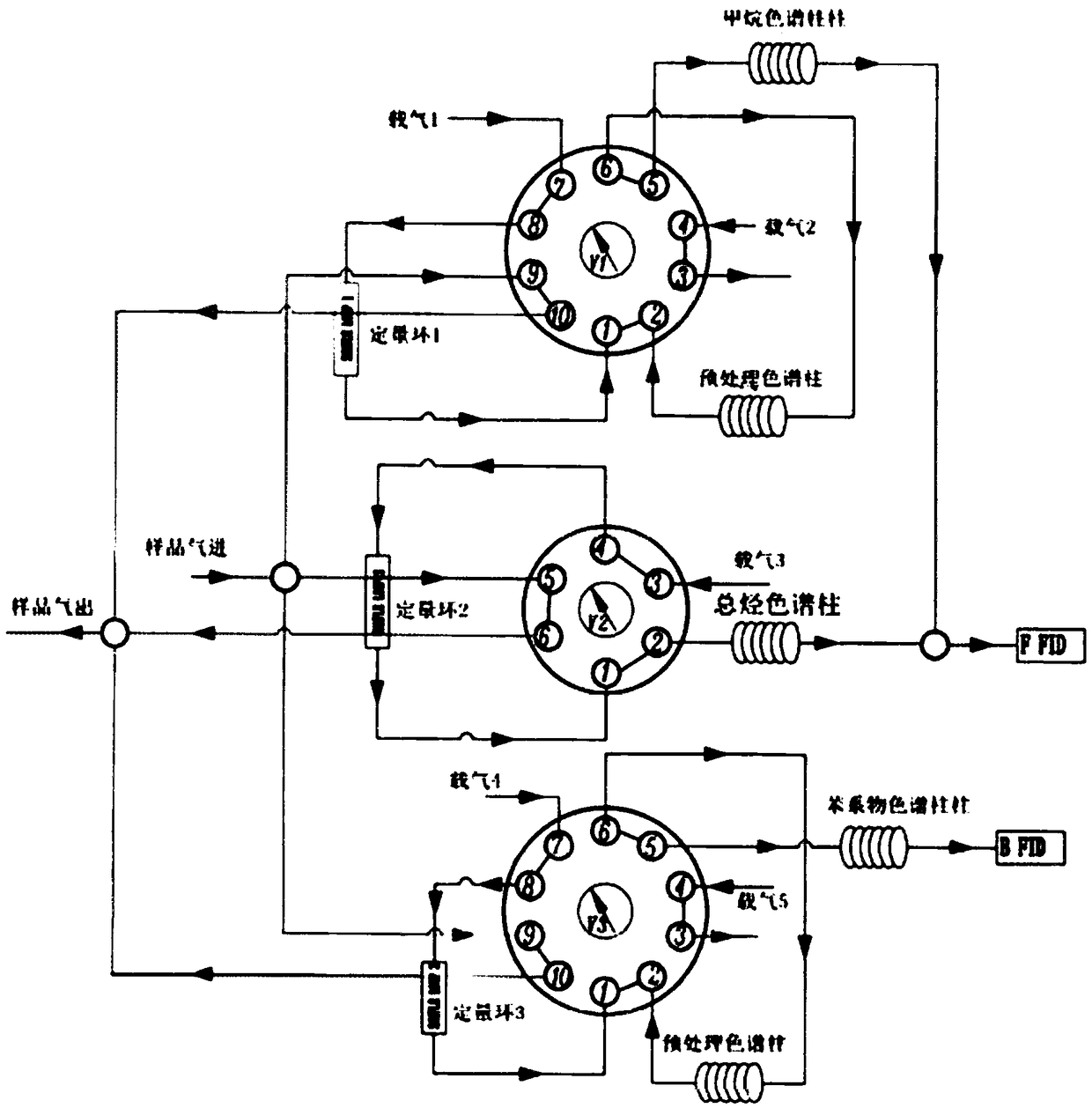

Volatile organic compound (VOCs) online monitoring system

The invention discloses a volatile organic compound (VOCs) online monitoring system and belongs to the field of monitoring of volatile organic compounds. The volatile organic compound (VOCs) online monitoring system mainly comprises a flue gas sampling probe, a heat tracing pipe, a pre-processing system, a gas carrier device, an electronic flow control system, a data analysis and processing system, an upper computer, a gas chromatographic analyzer and a hydrogen zero-stage air generator all-in-one machine; the flue gas sampling probe is connected with the pre-processing system and the gas chromatographic analyzer through the heat tracing pipe; the upper computer is connected with the gas chromatographic analyzer through signal control; the flue gas sampling probe, the gas carrier device and the hydrogen zero-stage air generator all-in-one machine are all connected with the gas chromatographic analyzer through the electronic flow control system. The gas chromatographic analyzer has double pre-processing effects, and an anti-blowing function is added on each set of switching valve; no memory effect of instrument analysis data is ensured, the repeatability is good, and the service life is long. The volatile organic compound online monitoring system disclosed by the invention is mainly used for monitoring of the volatile organic compounds.

Owner:山东润通科技有限公司

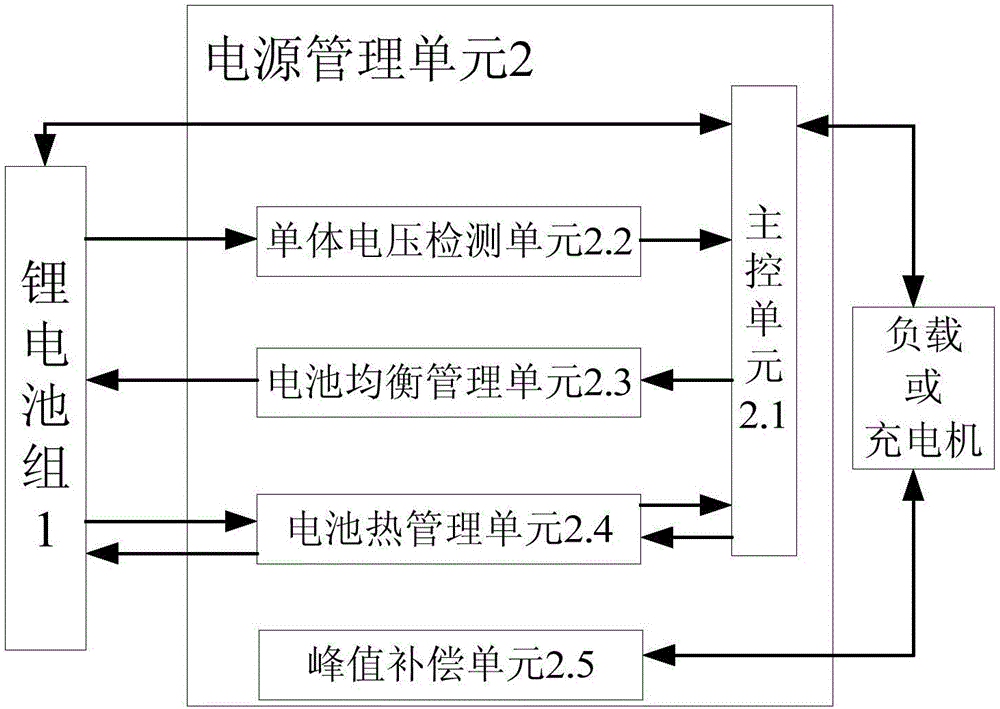

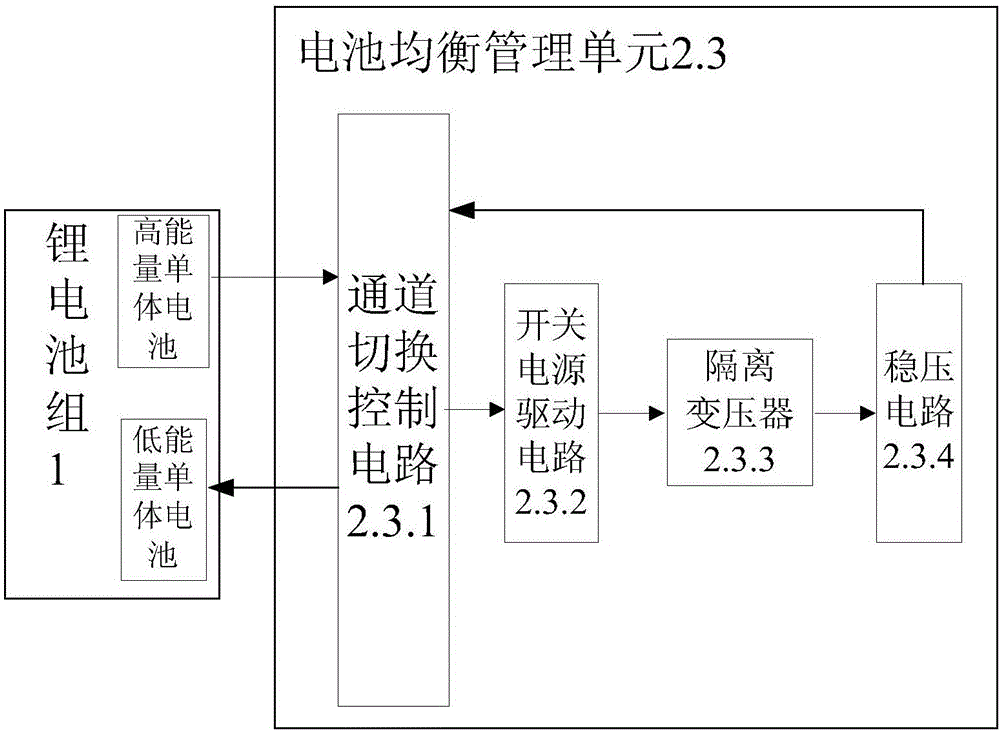

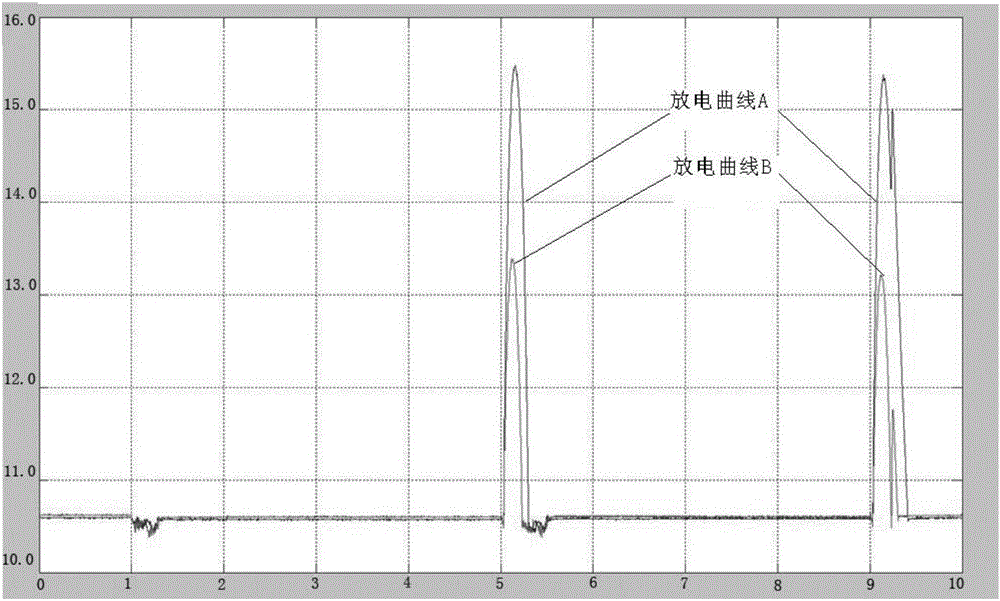

Servo power supply

ActiveCN106130123AMeet electricity demandGood chemical stabilityCharge equalisation circuitIndicating/monitoring circuitsSystems managementEnergy absorption

The invention provides a servo power supply which is applied to an electromechanical servo system and belongs to the electromechanical field. The servo power supply source comprises a lithium battery pack (1) and a power supply management unit (2). The power supply management unit (2) is composed of a main control unit (2.1), a monomer voltage detection unit (2.2), a battery equalization management unit (2.3), a battery thermal management unit (2.4) and a peak compensation unit (2.5). The lithium battery pack (1) provides a power supply required by the electromechanical servo system. The power supply management unit (2) carries out peak current compensation and regeneration energy absorption, and carries out system management and equalization on the lithium battery pack (1). The servo power supply provided by the invention can work for a long time, can be reused, has the advantages of large capacity, high reliability, low cost and small volume, can absorb regeneration energy, can carry out large pulse discharge, and is especially suitable for an aerospace servo power supply system.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

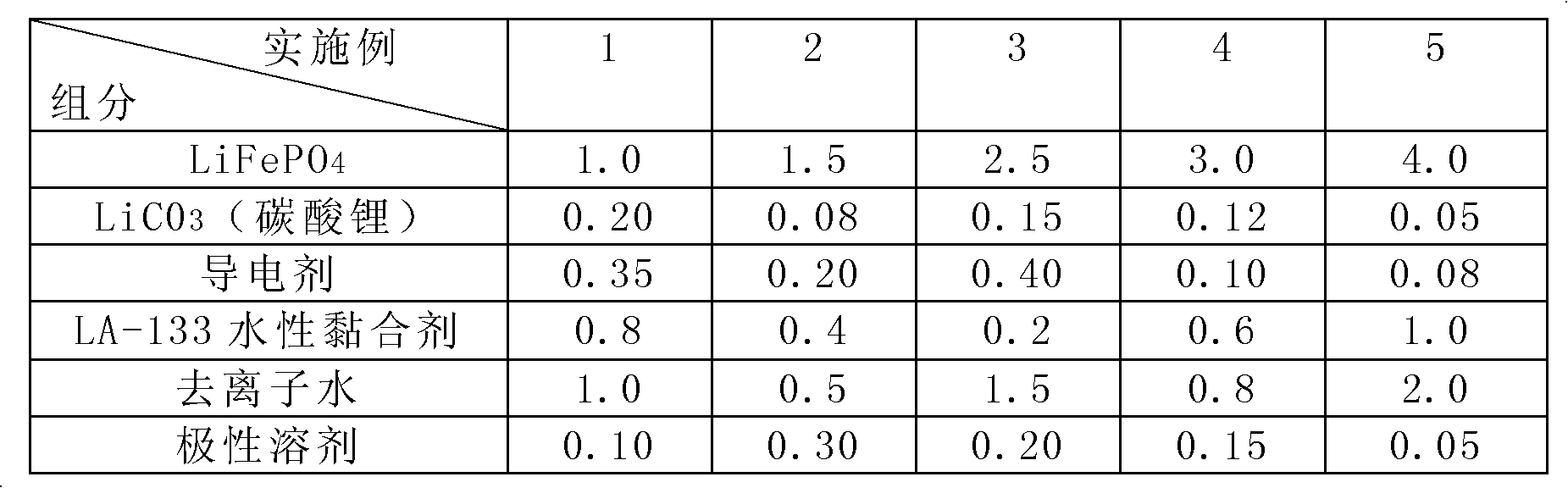

Mixed type anode sizing agent and lithium battery using anode sizing agent

InactiveCN101577325AHigh specific capacityExcellent specific energySecondary cellsActive material electrodesAdhesiveSolvent

The invention relates to a mixed type anode sizing agent and a lithium battery using the anode sizing agent; the mixed type anode sizing agent of the lithium battery comprises the following components with parts by weight: 0.5 to 2 parts of LiFePO4, 0.5 to 2 parts of LiCo2, 0.05 to 0.2 part of conductive agent, 0.1 to 1.0 part of aqueous adhesive, 0.5 to 2 parts of deionized water and 0.05 to 0.25 part of polar solvent. The positive plate of the lithium battery is coated with aluminum foil of the mixed type anode sizing agent. The mixed type anode sizing agent of the lithium battery adopts LiFePO4 material and LiCoO2 material for compatibility production, and the produced lithium battery has better specific capacity and specific energy, high power, excellent safety performance, long circulation service life and low production cost, and can be popularized in the practical application of lithium battery, stable discharge plateau, low self-discharge, no memory effect and wide application.

Owner:温岭市恒泰电池有限公司

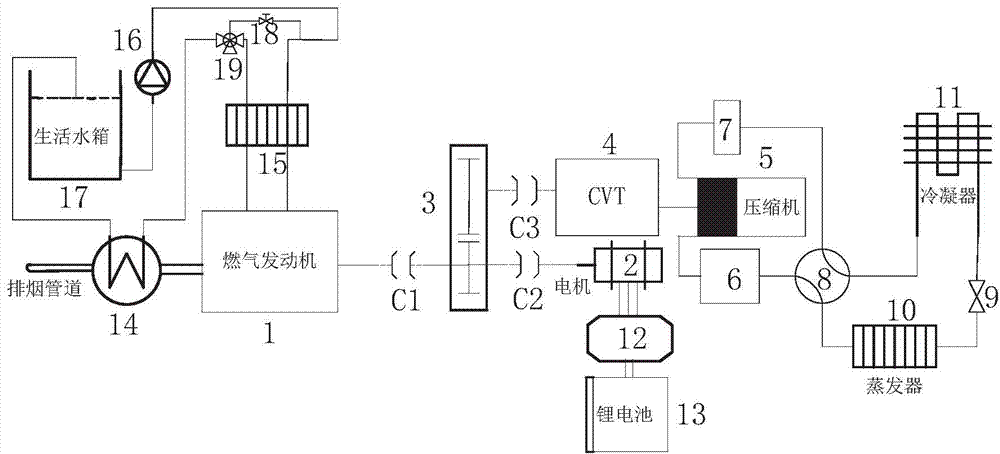

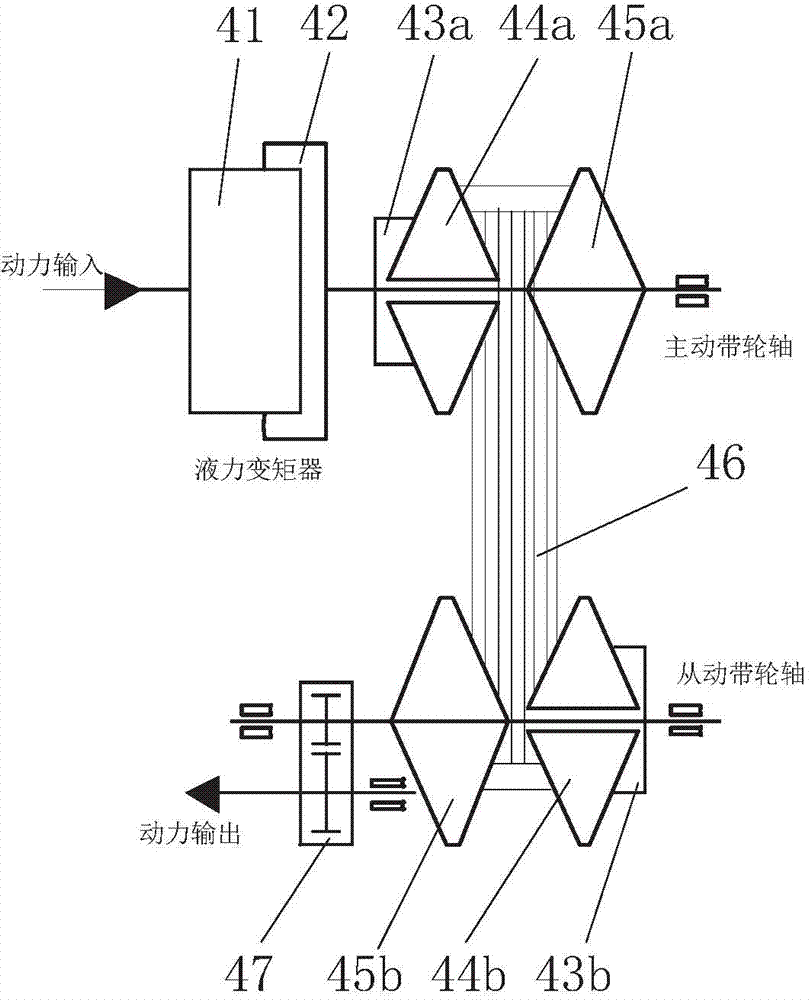

CVT (Continuously Variable Transmission)-based coaxial parallel hybrid power gas heat pump system

InactiveCN104776525AReduce consumptionImprove energy efficiencyAir treatment detailsHeating and refrigeration combinationsWhole bodyWheel cylinder

The invention discloses a CVT (Continuously Variable Transmission)-based coaxial parallel hybrid power gas heat pump system, and relates to a novel air conditioning system for combining a CVT device and a hybrid power gas heat pump system into an organic whole body. The system comprises a CVT device, an engine, a motor, a lithium iron phosphate battery pack, a compressor, an evaporator, a condenser, a waste heat recovery system and the like. The power of the engine and the motor is coupled and then transferred to a drive shaft through a hydraulic torque converter of the CVT, a metal belt type continuously variable transmission mechanism and a main speed reducer to drive the compressor in the heat pump system to operate. The transmission ratio in the drive system is adjusted by controlling hydraulic pressure in driving and driven belt wheel cylinders so as to change working radius on driving and driven belt wheels, and continuously variable transmission can be realized in an equivalent wide range, so that the optimal matching of the transmission system and the working condition of the engine is obtained, and the gas economy of the entire heat pump system is improved.

Owner:SOUTHEAST UNIV

Bionic preparing method for depositing calcium and phosphor active layer on memory alloy of nickel and titanium for medical use

InactiveCN1557506AInhibition releasePromotes firm deposit growthCoatingsProsthesisShape-memory alloyBiological activation

The present invention is the bionic process of preparing bioactive calcium phosphate layer on the surface of medical Ni-Ti memory alloy. The preparation process includes ultrasonic cleaning of medical Ni-Ti alloy with acetone, alcohol and distilled water successively; surface activation, and two-step bionic deposition of active calcium phosphate layer to form active calcium phosphate layer in two-layer structure on the surface of Ni-Ti alloy. The active calcium phosphate layer comprises transitional compact non-crystalline calcium phosphate layer of 1-10 micron thickness and porous octacalcium phosphate or surface bone-like crystalline apatite layer of 10-100 micron thickness. During the surface activation, boiling H2O2 aqua of 10-60 concentration is first used for treatment of 10-90 min, and NaOH aqua of 1-10 M concentration at 30-80 deg.c is then used for soaking after flushing for 6-48 hr.

Owner:SOUTHEAST UNIV +1

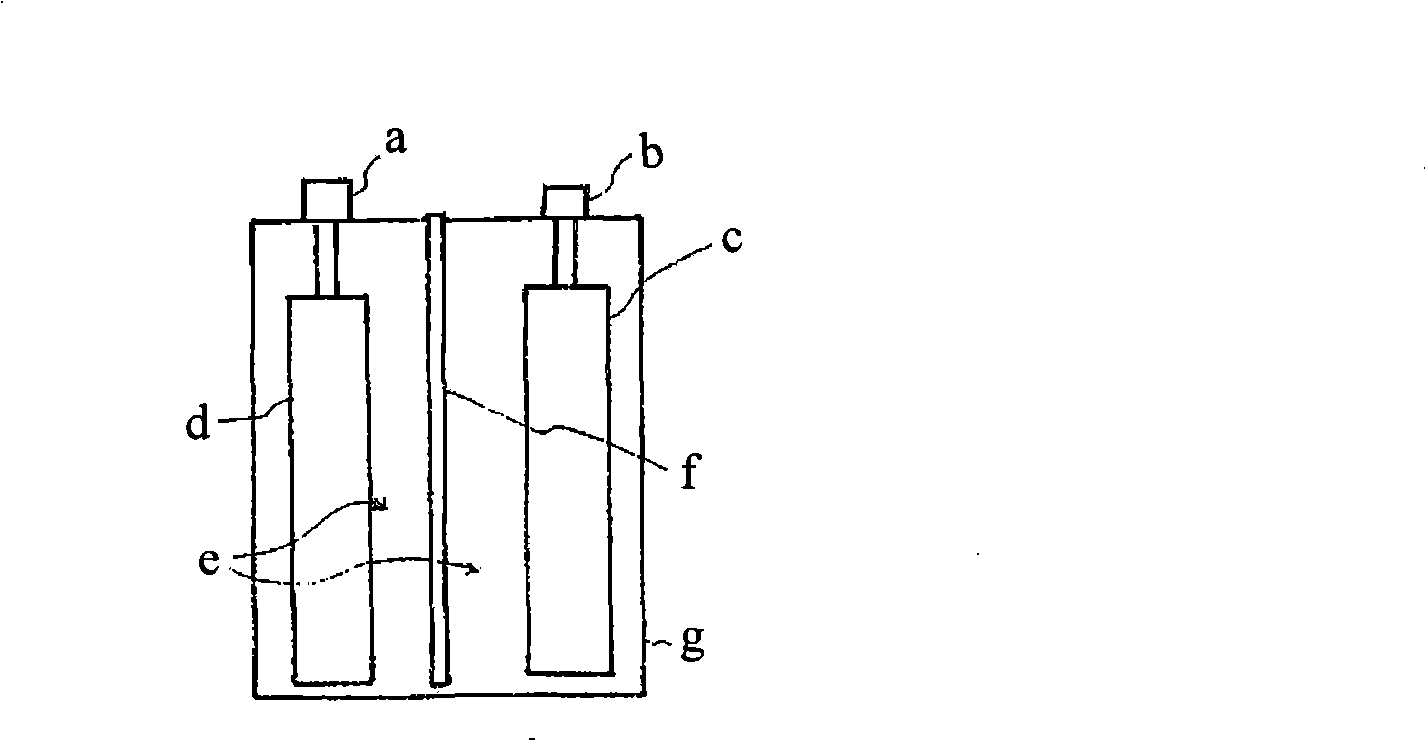

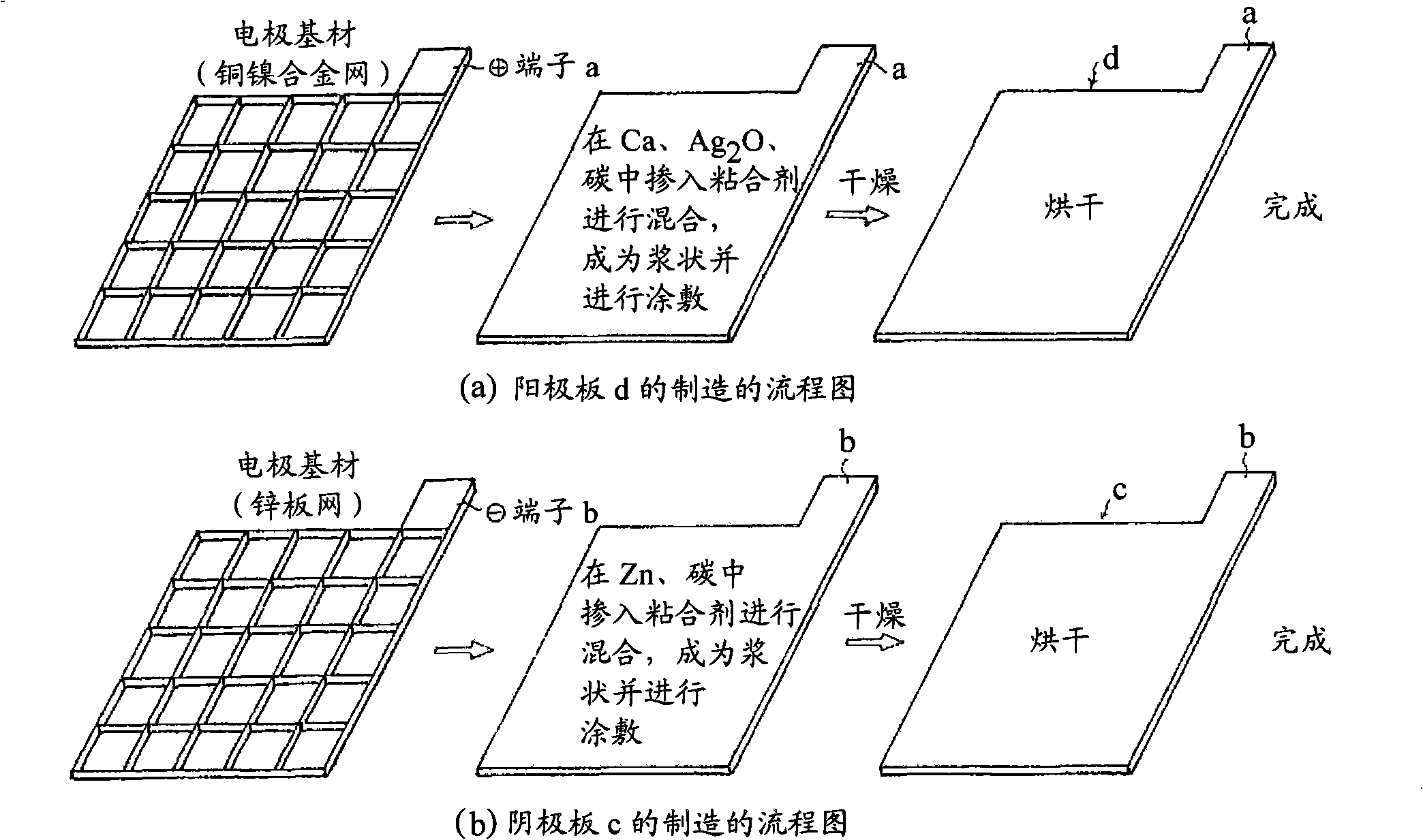

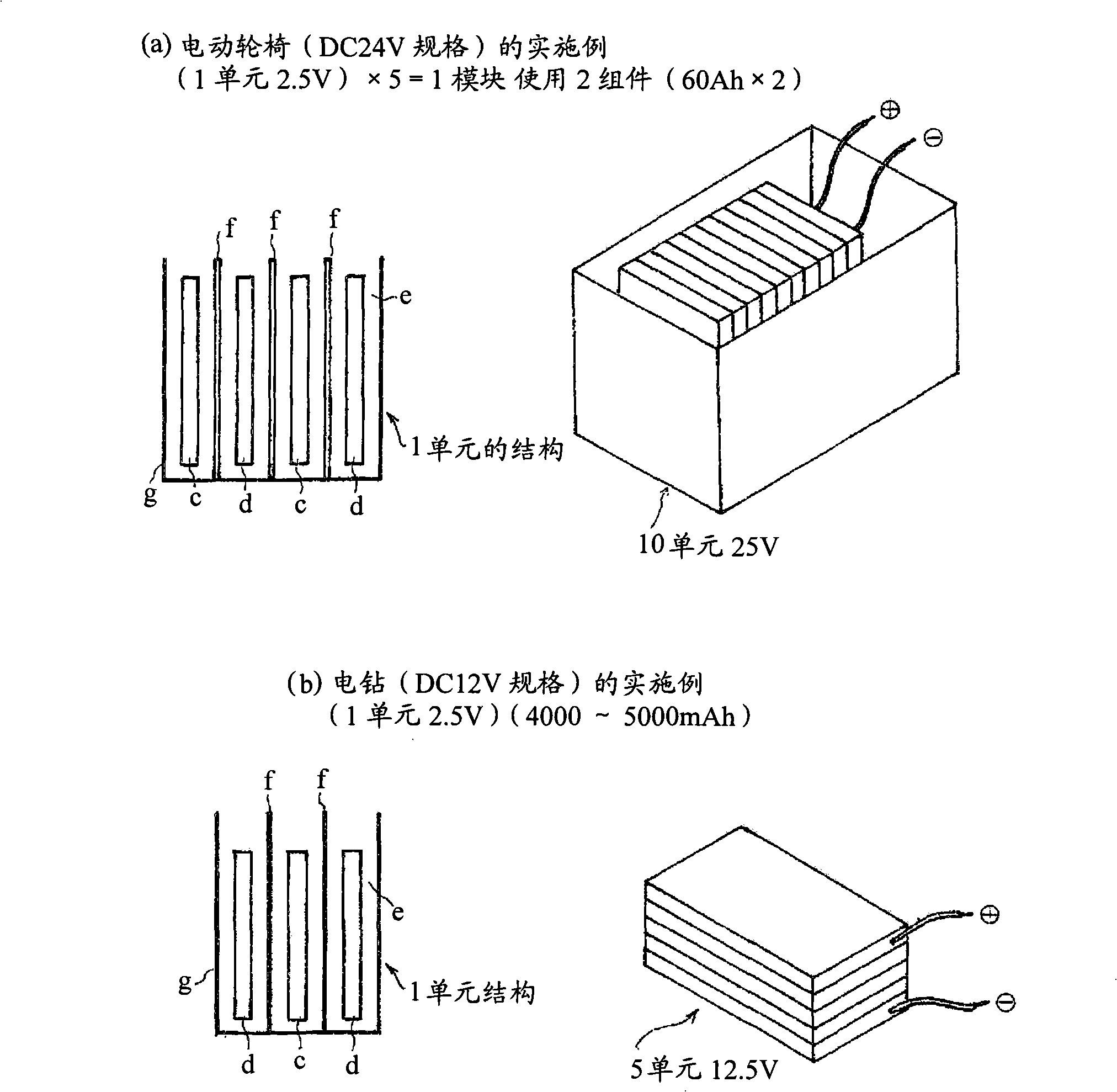

Lead-free battery and vehicle system using the same

InactiveCN101346849ADisposal is easyFast chargingSilver accumulatorsAlkaline accumulator electrodesElectrical batteryEngineering

It is possible to provide a high-performance and high-capacity secondary cell without containing polluting substance such as lead in an electrode plate or sulfuric acid in electrolyte. It is also possible to provide a vehicle system which uses a lead-free battery of higher performance and higher capacity than a lead battery without using lead or sulfuric acid causing pollution and has more excellent high-speed charge / discharge characteristics than the lead battery, which enables a long-distance travel by external charging at once. Provided is a secondary battery including: an anode having an electrode containing calcium, silver oxide, and carbon; a cathode has an electrode containing zinc and carbon; and alkali aqueous solution as electrolyte. By using the lead-free battery, there is provided the vehicle system including a first and a second battery pack, an in-wheel generator attached to a wheel, a vehicle power motor, and a charge / discharge switching device having a control unit for automatically switching between the first and the second battery pack.

Owner:森幸信

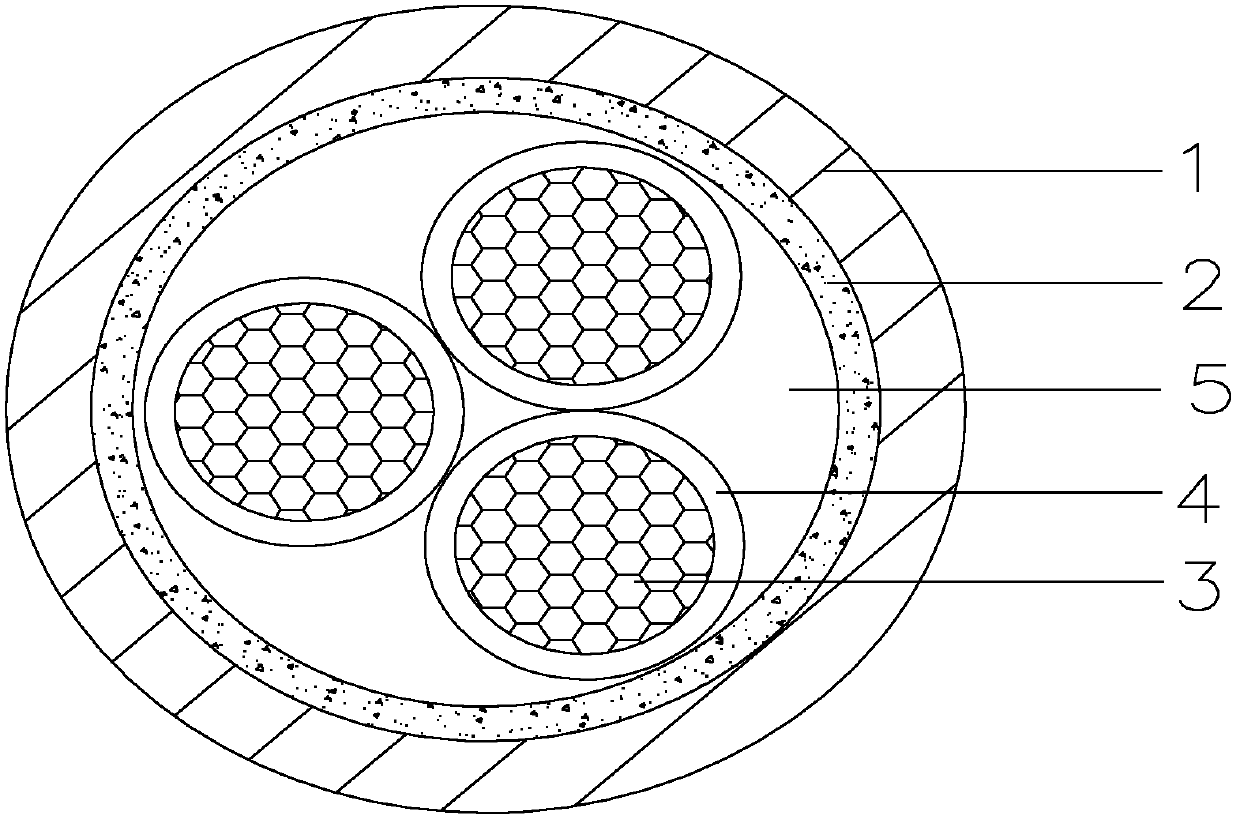

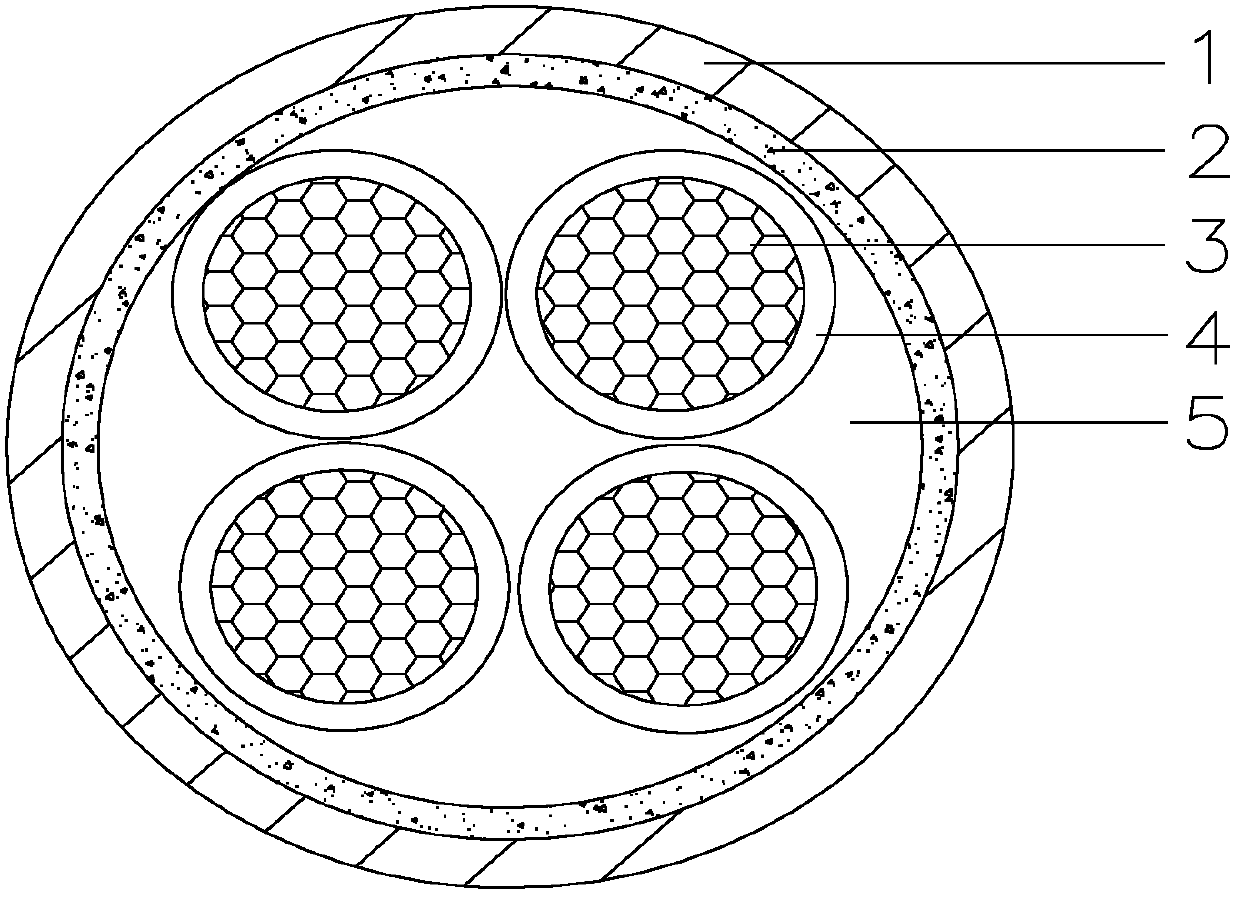

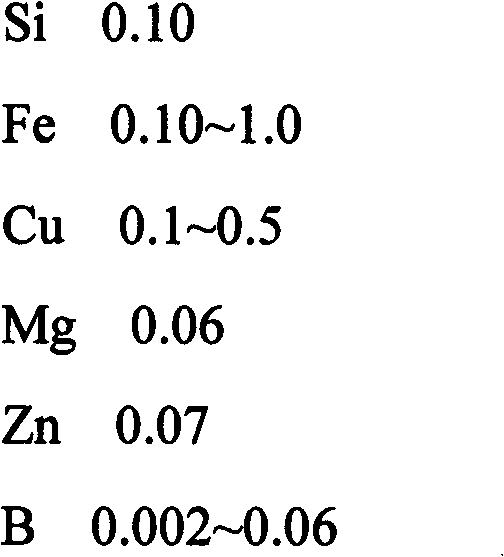

Aluminum alloy cable core and production technology of aluminum alloy cable core

InactiveCN104064254AStrong anti-corrosion and anti-creep performanceNo memory effectPower cablesMetal/alloy conductorsElectrically conductiveCorrosion prevention

The invention discloses an aluminum alloy cable core and a production technology of the aluminum alloy cable core. The aluminum alloy cable core comprises, by weight, 0.3% to 0.6% of copper, 0.1% to 0.3% of iron, 0.02% to 0.05% of silicon, 0% to 0.02% of titanium, 0% to 0.02% of potassium, 0% to 0.001% of zinc, 0%-0.001% of manganese, 0% to 0.0003% of magnesium and the balance aluminum. The finished circular aluminum rod is obtained sequentially through the steps of primary aluminum liquid electrolysis, component analysis, copper-iron agent adding, electromagnetic stirring, determining of copper-iron component content in the aluminum liquid, temperature adjustment, inner-furnace purification, inner-furnace standing, outer-furnace purification, online gas removal, continuous casting, blank shearing, continuous rolling, cooling and detecting. The aluminum alloy cable core is mainly used for a high-conductivity aluminum alloy cable, the cable manufactured with the aluminum alloy cable core has the higher corrosion resistance and the higher creep resistance compared with a copper core cable, the elasticity is 40% lower than that of the copper core cable, the flexible performance is 30% higher than that of the copper core cable, and the cable is free of the memory effect and good in heat stability.

Owner:STATE GRID CORP OF CHINA +1

Method for producing upper and lower base plate electrode of plasma display screen

InactiveCN1750216AQuality improvementImprove yield rateCold cathode manufactureMedia layerProtection layer

This invention provides a manufacturing method for up and down base plate electrodes of a plasma display screen including a glass upper base plate and a glass lower base plate, in which, a transparent electrode, a BUS electrode, a black strip, an upper transparent medium layer and a Mgo medium protection layer are orderly designed on the upper base plate and an ADD electrode, lower medium layer, a baffle and red, green and blue fluorescent powder are orderly set on the lower base plate. The photoetching technology is applied to form the display electrode and the addressing electrode, which intentionally enlarges the pattern of the electrode to let the edges of the electrode connect in short circuit then cuts off unnecessary edges with laser to eliminate the edge effect.

Owner:四川世纪双虹显示器件份有限公司

Lithium battery anode slurry for starting power supply of motorcycle and car starting power supply and lithium battery

InactiveCN101841028AHigh specific capacityImprove securityCell electrodesSecondary cellsLithium vanadium phosphate batteryLithium iron phosphate

The invention relates to lithium battery anode slurry for a starting power supply of a motorcycle and a car and a lithium battery. The lithium battery anode slurry comprises the following components in parts by weight: 1.0 to 4.0 parts of LiFePO4, 0.05-0.2 part of Li2CO3, 0.05-0.4 part of conductive agent, 0.1-1.0 part of water adhesive, 0.5-2 parts of de-ionized water and 0.1-0.35 part of polar solvent. A positive plate of the lithium battery is an aluminium foil coved by the hybrid anode slurry. The lithium battery hybrid anode slurry is produced by the compatibility of a lithium iron phosphate material and a lithium carbonate material. The invention has the advantages that the lithium battery has excellent specific capacity and specific energy, high power, good safety performance, long cycle service life and low generation cost, and can replace a lead-acid battery to be served as the starting power supply of the motorcycle and car, thus filling the technology gap of utilization of a lithium iron phosphate battery in the starting power supply in China.

Owner:温岭市恒泰电池有限公司

Aluminum alloy round bar and production method thereof

InactiveCN103451480AStrong anti-corrosion and anti-creep performanceSmall elastic wallElectrolysisPotassium

The invention discloses an aluminum alloy round bar and a production process thereof. The aluminum alloy round bar comprises the following chemical components in percentage by weight: 0.2-0.5% of copper, 0.1-0.3% of iron, 0.02-0.05% of silicon, 0-0.02% of titanium, 0-0.02% of potassium, no more than 0.001% of zinc, no more than 0.001% of manganese, no more than 0.0003% of magnesium and the balance of aluminum. The production process sequentially comprises the following steps: electrolyzing a primary aluminum solution, performing component analysis, adding copperon, electromagnetically stirring, determining copper and iron contents in the aluminum liquid, adjusting the temperature, purifying in a furnace, standing in the furnace, purifying outside the furnace, performing on-line degassing, continuously casting, shearing a blank, continuously rolling, cooling, and inspecting to obtain the finished round aluminum bar. The aluminum alloy round bar disclosed by the invention is mainly used for processing of high-conductivity aluminum alloy cables. Compared with copper core cables, the cables produced from the aluminum alloy round bar have better corrosion resistance and creep resistance, the elasticity is reduced by 40%, and the flexibility is increased by 30%; and the cables produced from the aluminum alloy round bar have no memory effect, and are favorable in heat stability.

Owner:HENAN HUILONG ALUMINUM IND

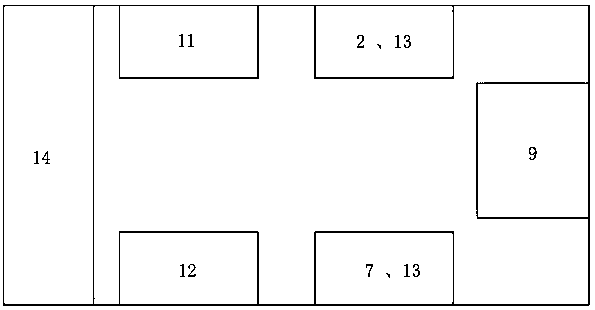

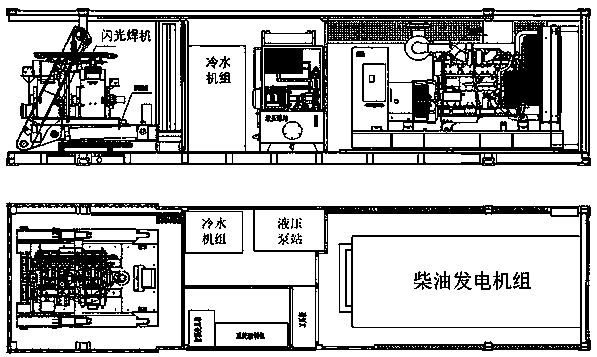

Movable steel rail flash welding machine driven by large-power energy storage power supply device

ActiveCN110125523AReduce shock loadHigh impact loadWelding electric supplyCapacitanceElectrical battery

The invention relates to the field of steel rail flash welding, in particular to a movable steel rail flash welding machine driven by a large-power energy storage power supply device. The movable steel rail flash welding machine comprises a welding machine, welding machine auxiliary equipment and the power supply device. The power supply device comprises a battery set power supply part and a super-capacitor set power supply part. The battery set power supply part supplies power to the welding machine auxiliary equipment and the super-capacitor set power supply part. The super-capacitor set power supply part supplies power to the welding machine. During preparation before welding, the battery set power supply part continuously supplies power to an auxiliary system so that preparation conditions before welding can be met, and the battery set power supply part charges the super-capacitor set power supply part. When welding is needed, the super-capacitor set power supply part supplies power to the welding machine. A battery set and a super-capacitor set are matched, under the situation that load fluctuation is large, the battery set high-strength power supply probability is obviously reduced, the energy density of a power source can be improved, and meanwhile the peak current requirement is met.

Owner:成都西南交通大学产业(集团)有限公司 +1

Aluminum alloy cable

InactiveCN103377758AImprove conductivityLow conductivityFlexible cablesFlexible conductorsInsulation layerHigh conductivity

The invention relates to an aluminum alloy cable including an armor tape, a jacket, an insulation wire core and filling material. An outer of the armor tape is wrapped with the jacket. The insulation wire core is arranged in the armor tape. The filling material is disposed in a gap between the armor tape and the insulation wire core. The insulation wire core is made of an aluminum alloy conductor and an insulation layer wrapping the aluminum alloy conductor. The aluminum alloy conductor is an 8030 aluminum alloy conductor. Compared with the prior art, the aluminum alloy cable has the advantages of high conductivity, high creep and compaction resistance, high tensile strength, high yield strength, high elongation, small springback value, no memory effect, easy installation and the like.

Owner:SHANGHAI XINYI ELECTRICAL CIRCUIT EQUIP

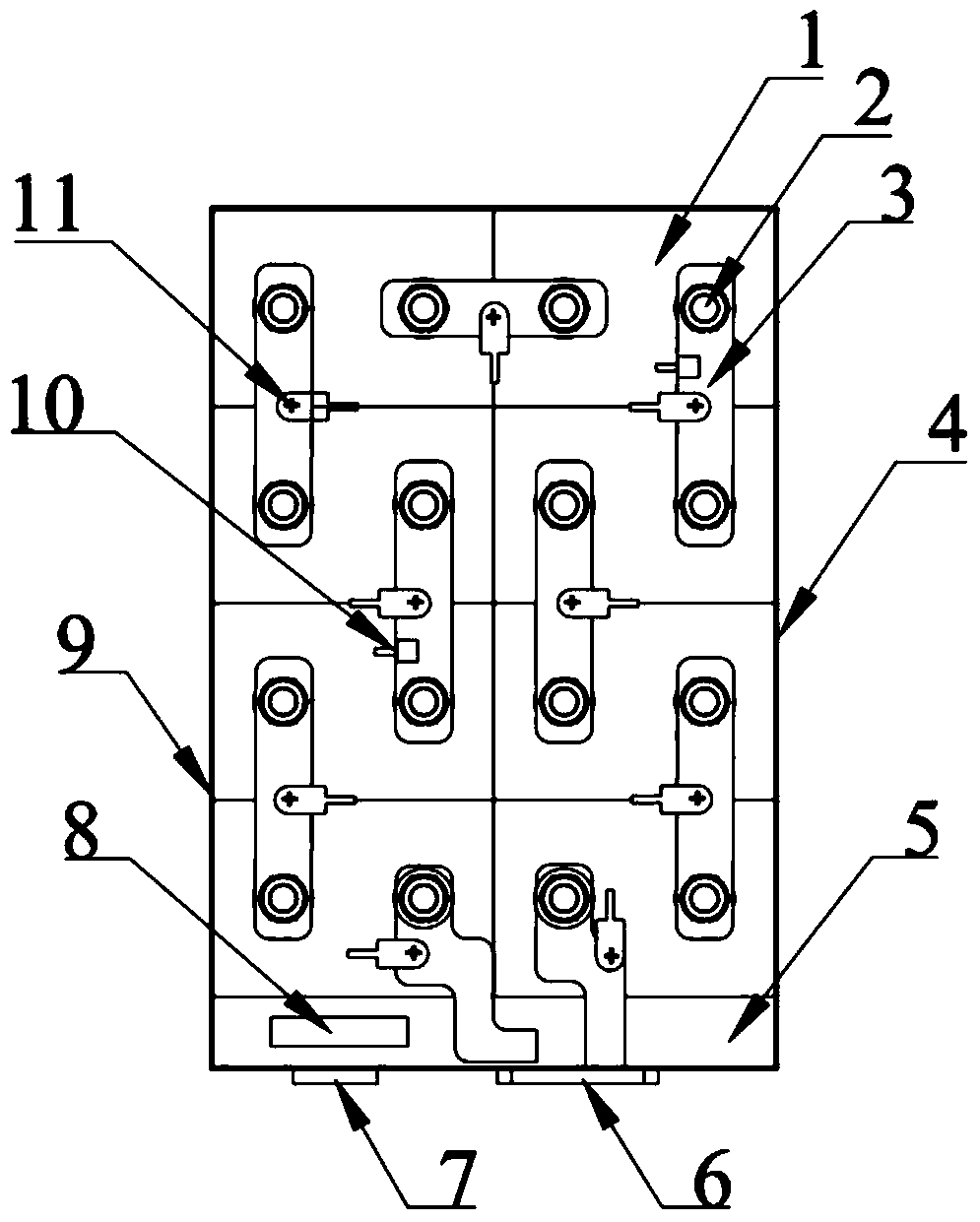

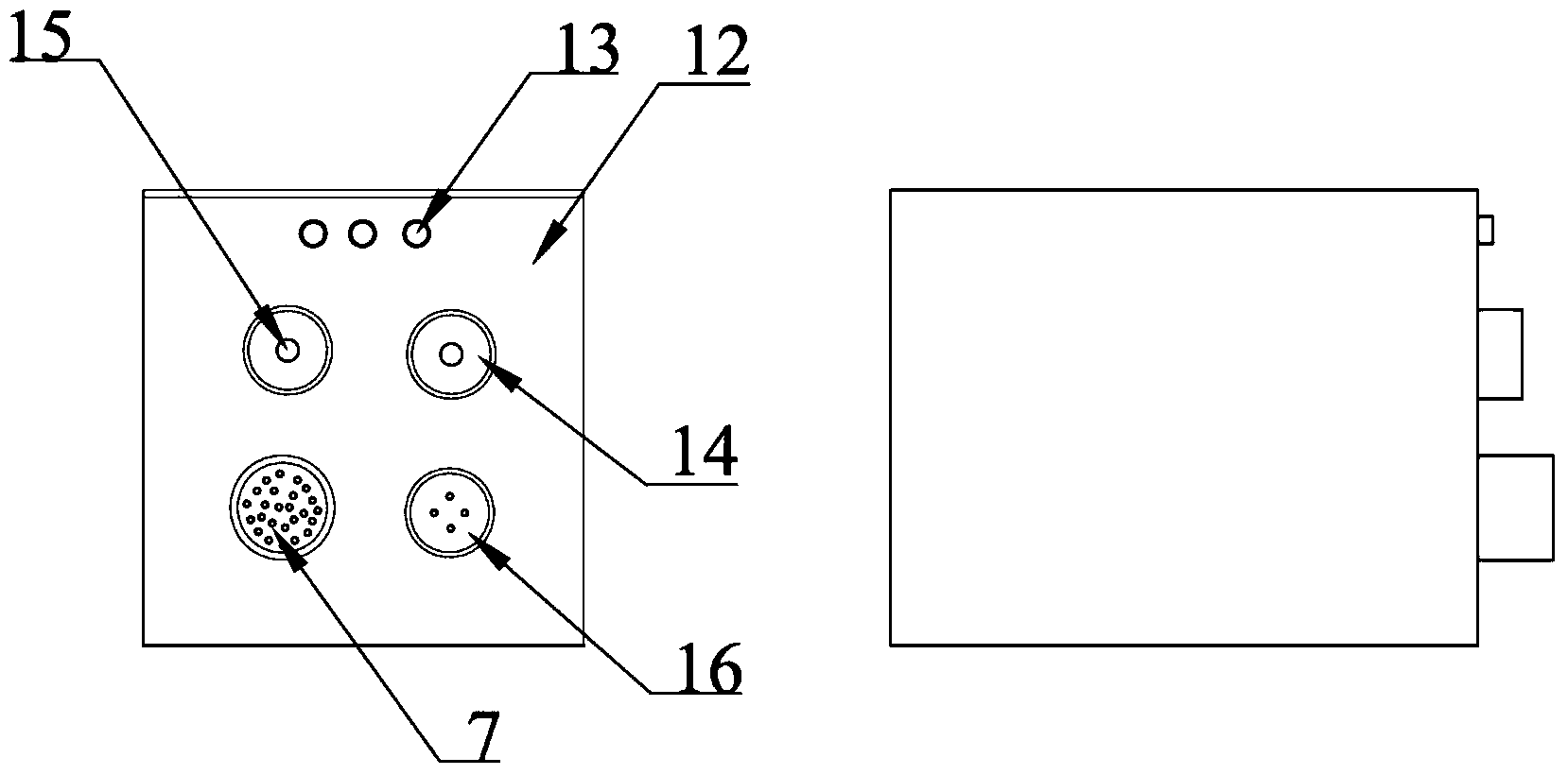

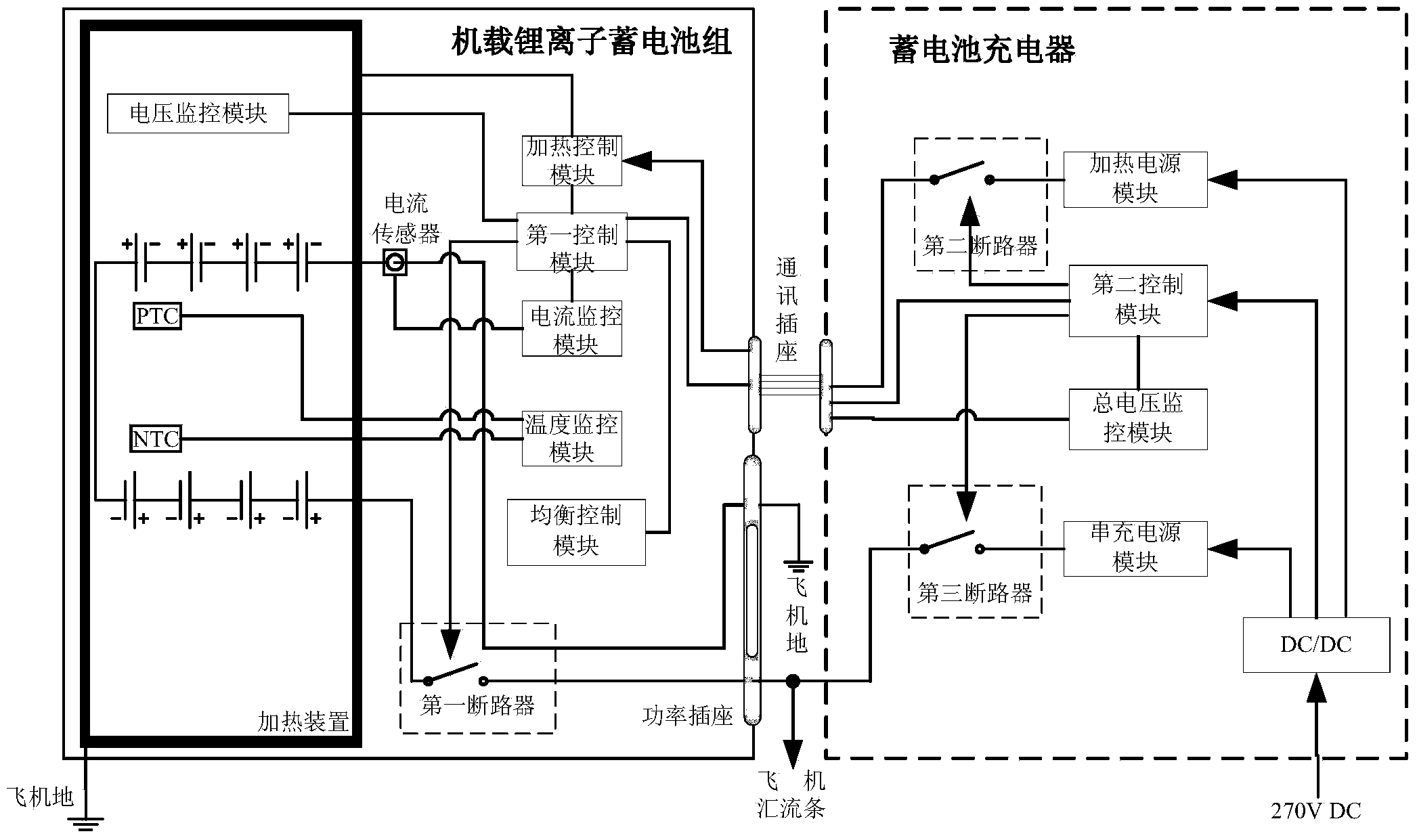

Onboard lithium ion battery system

ActiveCN104269899AImprove power densityIncrease energy densitySafety/protection battery circuitsElectric powerPower flowElectrical battery

The invention discloses an onboard lithium ion battery system. The onboard lithium ion battery system comprises a lithium ion battery pack and a battery charger, wherein the lithium ion battery pack is connected with the battery charger through a power socket and a communication socket; the lithium ion battery pack comprises a plurality of series-wound single batteries and a heating device; the lithium ion battery pack further comprises a voltage monitoring module, a current monitoring module, an equilibrium control module, a first control module and a first breaker; the battery charger comprises a series-wound charging power module, a heating power module, a total voltage monitoring module, a second control module, a second breaker, a third breaker and a DC / DC converter. The onboard lithium ion battery system can well guarantee the safety of the lithium ion battery pack.

Owner:武汉中原长江科技发展有限公司 +1

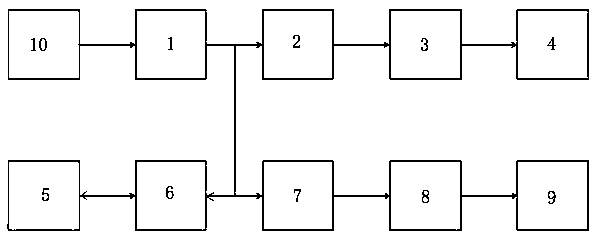

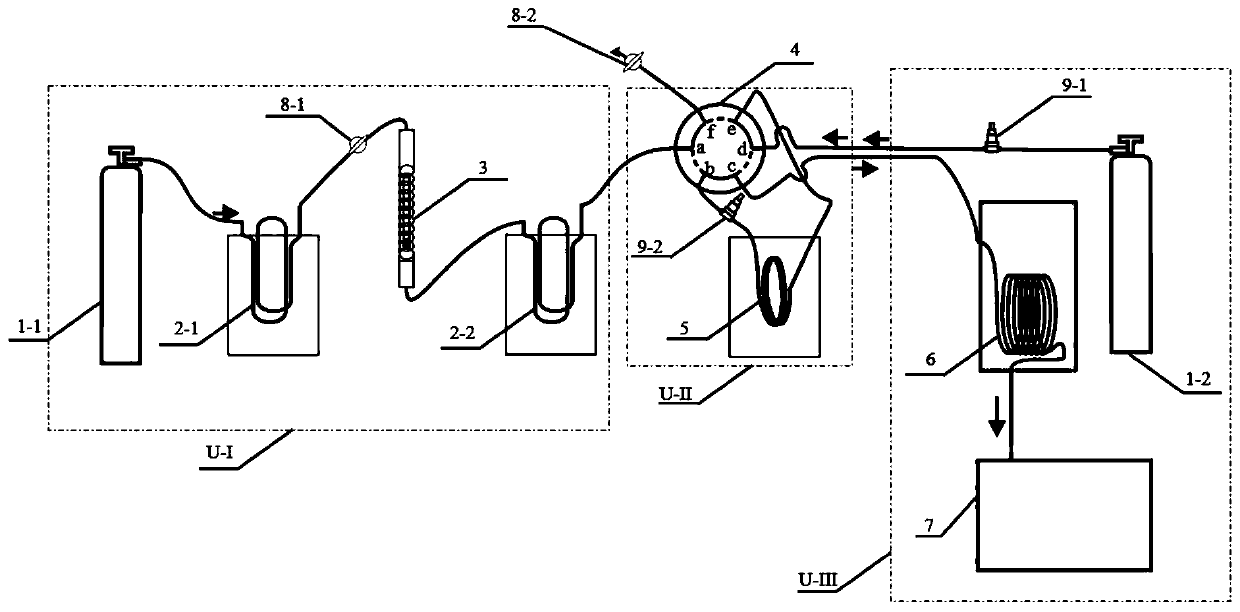

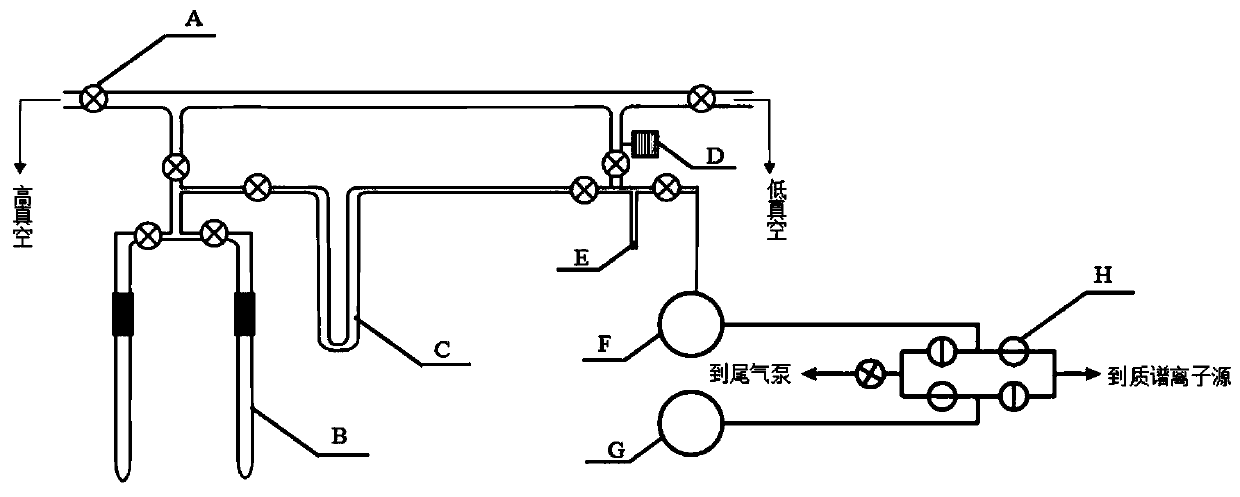

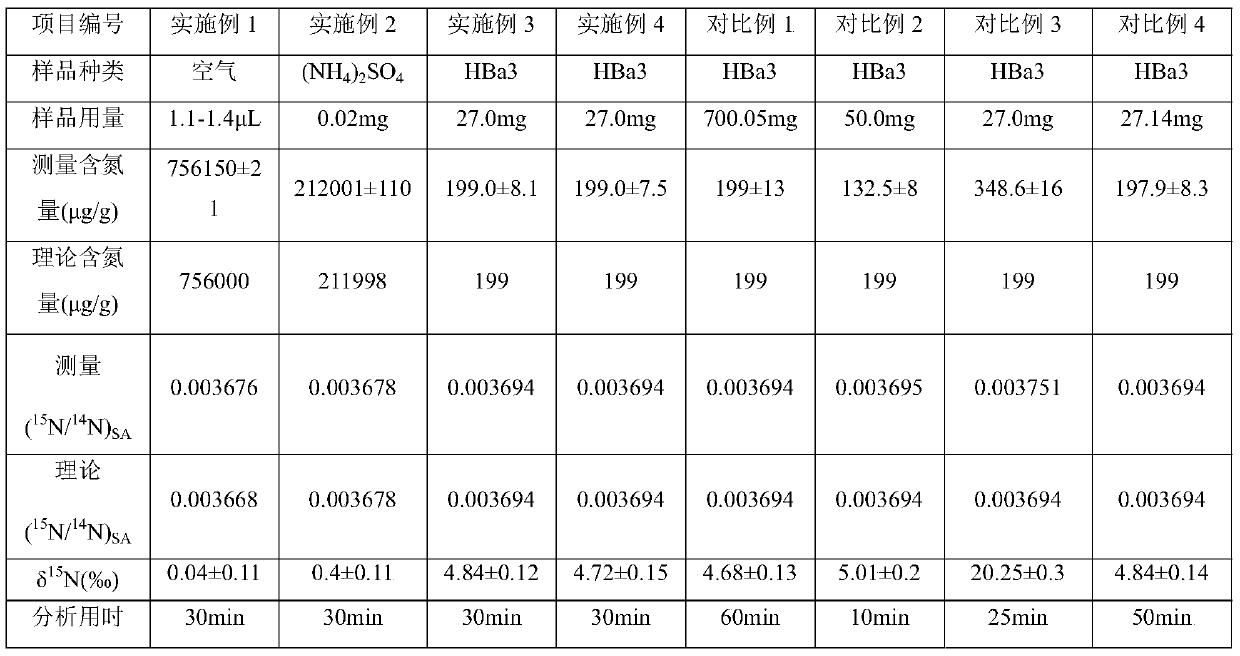

Trace nitrogen isotope analysis system and method

The invention belongs to the technical field of isotope analysis and discloses a trace nitrogen isotope analysis system and a trace nitrogen isotope analysis method using the same. The analysis systemcomprises a primary purification unit (U-I), a control unit (U-II) and a secondary purification sampling unit (U-III), wherein the primary purification unit (U-I), the control unit (U-II) and the secondary purification sampling unit (U-III) are sequentially connected with one another through a connecting pipeline. With the system and method provided by the invention adopted, the analysis of tracenitrogen isotope in a gaseous sample or a solid sample can be realized. The system and the method have the advantages of high precision, high accuracy and the like.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

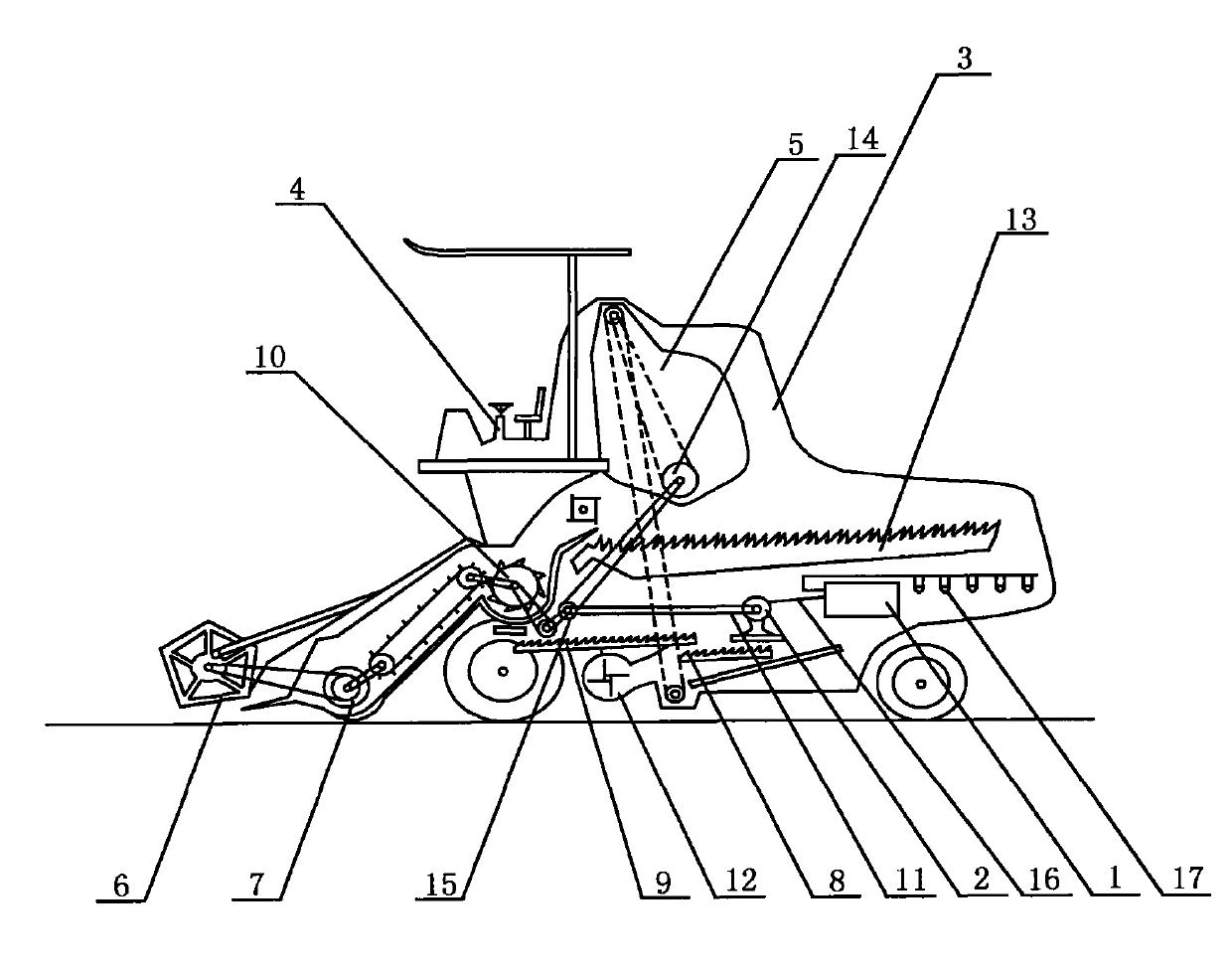

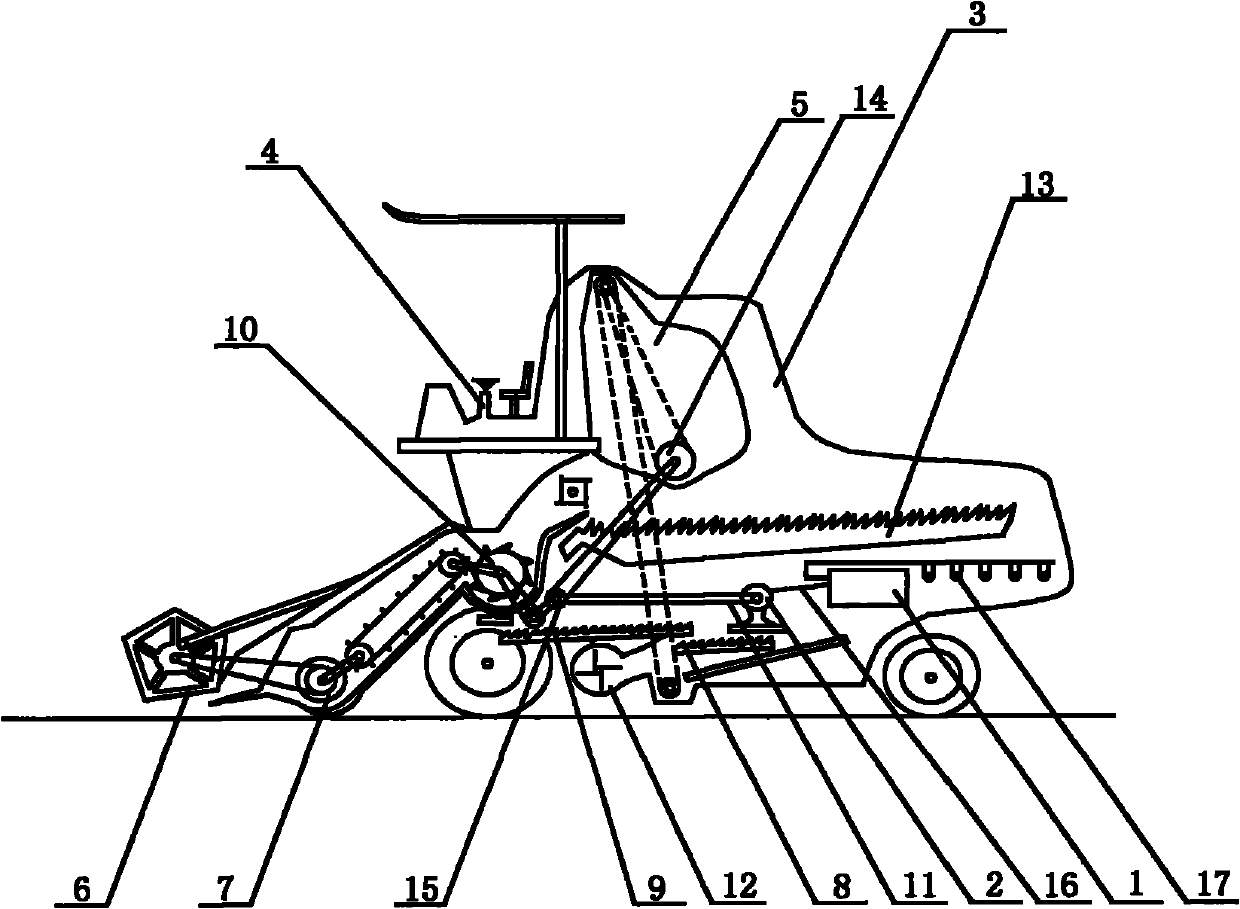

Harvester using lithium ion battery new energy as power unit

InactiveCN101904249AExtended service lifeEasy to useBatteries circuit arrangementsMowersElectrical batteryNew energy

The invention relates to a harvester using lithium ion battery new energy as a power unit, and belongs to the technical field of new energy application. An electric harvester mainly comprises a harvester device and a lithium ion battery power unit, wherein the lithium ion battery power unit charges lithium ion batteries through a power grid and storages the current; after a circuit switch is switched on, the lithium ion batteries supply power to a matched motor so as to convert the electric energy into mechanical energy; and the mechanical energy is respectively transmitted to various working parts of the harvester through a conveyor belt and a transmission wheel so as to complete the harvesting operation such as reeling, stripper header push and convey, threshing, grain convey, grain unloading, straw raking and the like of grain crops according to the operation order. The rear of the harvester is provided with a light-emitting diode for lighting, which is powered by the lithium ion batteries, so as to facilitate checking the threshing quality of the harvester at any time and making timely adjustment.

Owner:WUXI TONGCHUN NEW ENERGY TECH

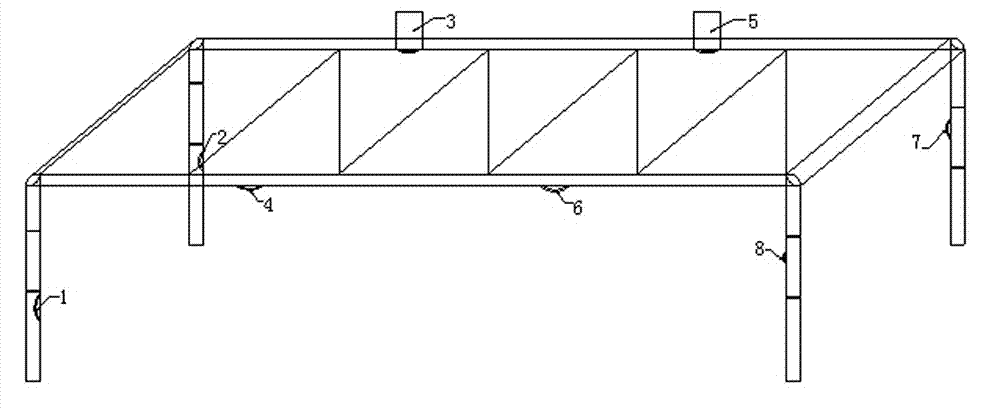

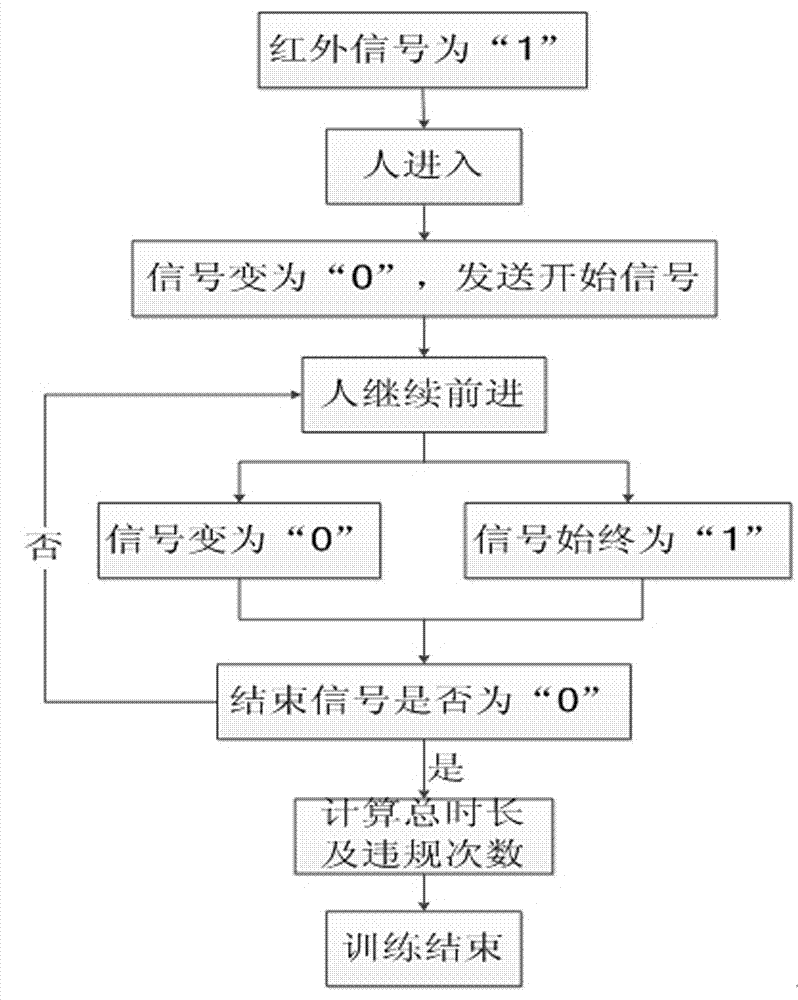

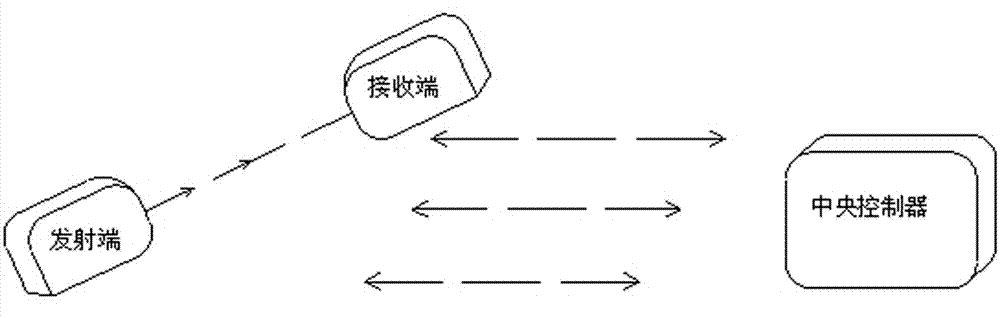

Intelligent efficient crawl training system and method

InactiveCN103751998AImprove training efficiencyScalableSport apparatusProcessing elementEmbedded system

The invention discloses an intelligent efficient crawl training system and method. The intelligent efficient crawl training system comprises a power supply unit, an infrared signal collection unit, an infrared signal transmission and CPU (Central Processing Unit) processing unit and a serial port output unit. The structure of the intelligent efficient crawl training system is formed by an entrance timing collection infrared transmitter (1), an entrance timing collection infrared receiver (2), a first collector infrared transmitter (3), a first collector infrared receiver (4), a second collector infrared transmitter (5), a second collector infrared receiver (6), an exit timing collection infrared transmitter (7) and an exit timing collection infrared receiver (8) which are connected in turn. According to the intelligent efficient crawl training system and method, the carrying is convenient, the training can be intelligently guided, the operation is simple, and the intelligent efficient crawl training system and method is suitable for popularization and application.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

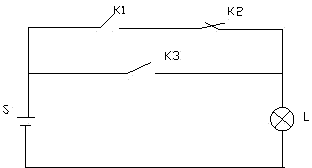

Table lamp

InactiveCN103791306AReduce volumeIncrease energy densityPoint-like light sourceElectric circuit arrangementsMicrocontrollerMicrocomputer

The invention relates to a table lamp. The table lamp comprises a base and a lamp holder, wherein the base is connected with the lamp holder through a fixing pin, a changeable battery is contained in the base, an alarm clock and a control module are arranged above the base, the control module comprises a single chip microcomputer and three control switches, the control switches are the manual control switch, the timing normally-closed switch and a sound control normally-opened switch, and the manual control switch is connected with the timing normally-closed switch in series and then is connected with the sound control normally-opened switch in parallel. The table lamp is simple in structure and convenient to use. On one hand, a user can be forcibly reminded to pay attention to rest, and on the other hand, the table lamp is automatically started after a set time is up, and the number of unnecessary troubles caused to the user is reduced.

Owner:冉岳航

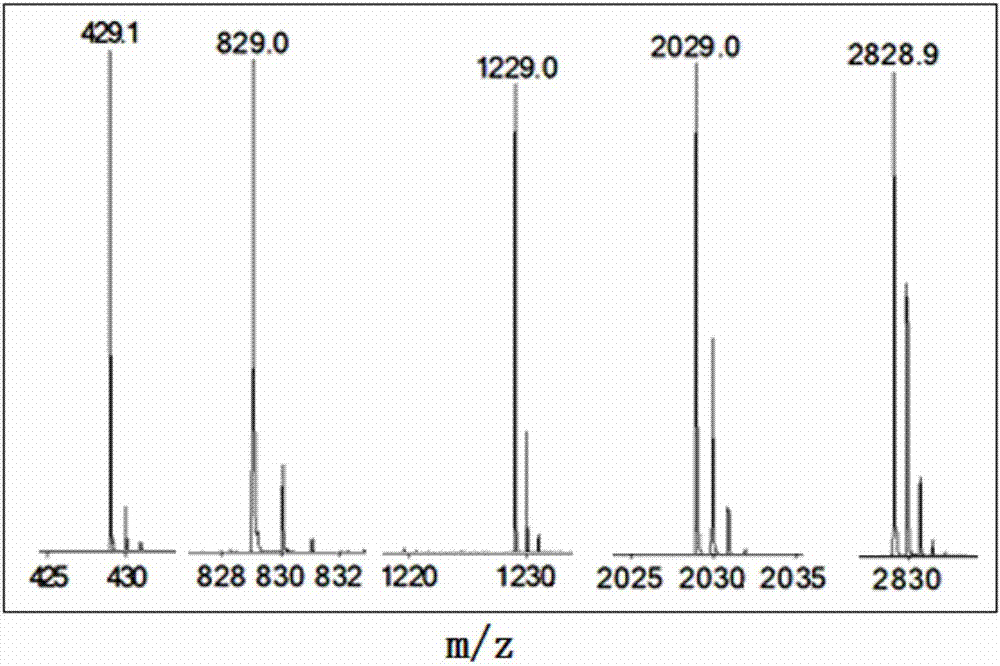

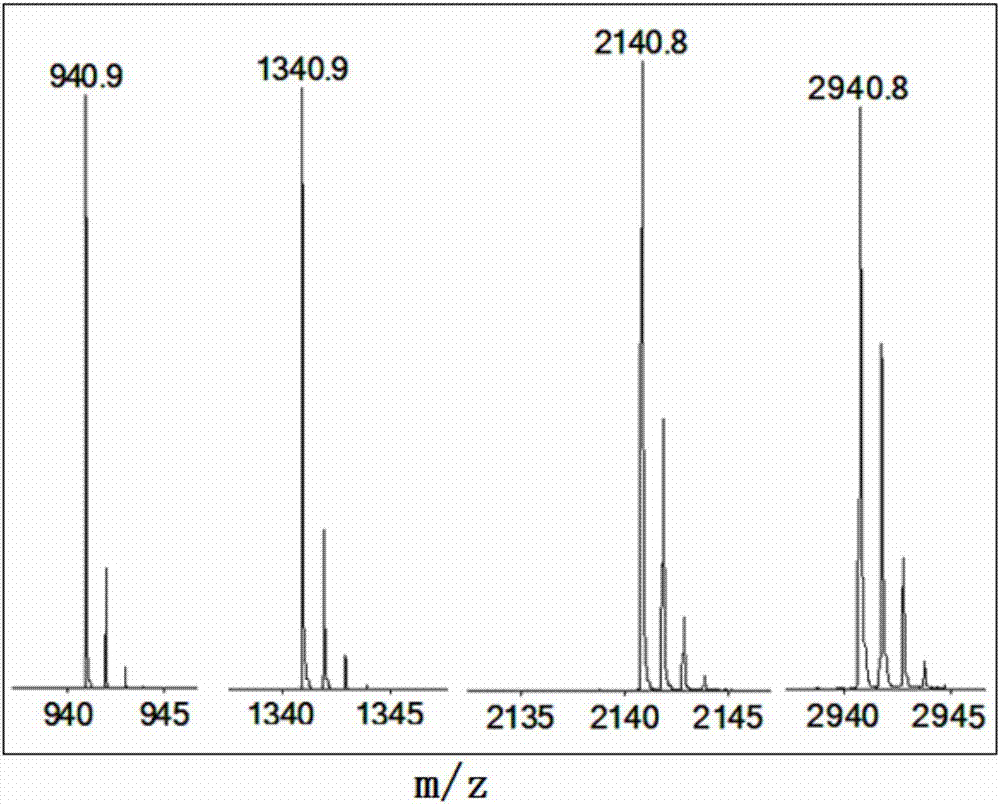

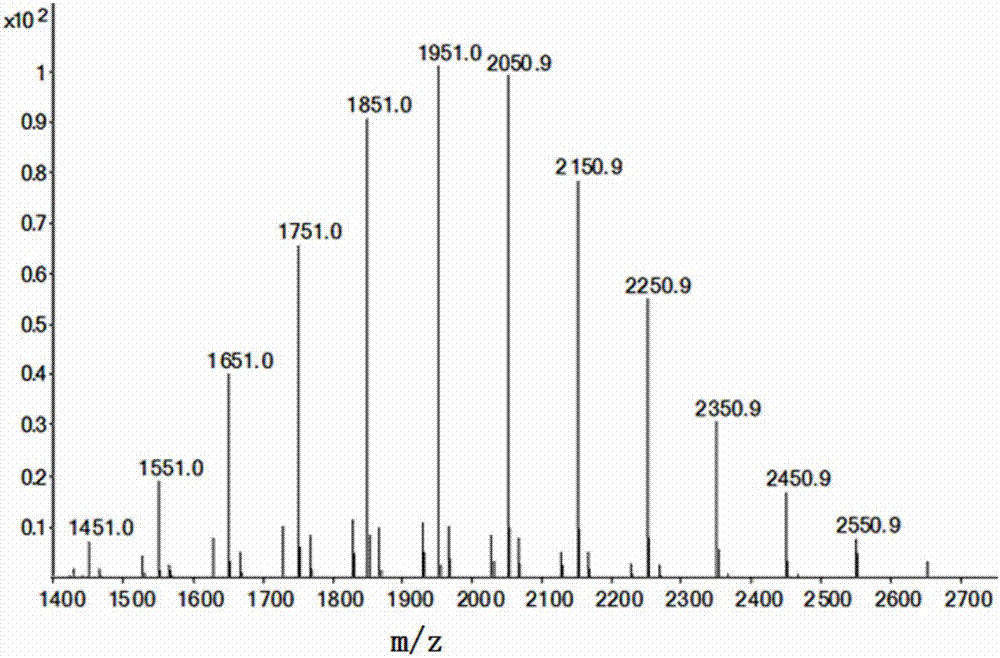

Application of substituted cyclotetraphosphazene compounds

ActiveCN107957446AEasy to grabApplied Concentration ReducedGroup 5/15 element organic compoundsMaterial analysis by electric/magnetic meansChemical structureMemory effect

The invention discloses application of substituted cyclotetraphosphazene compounds. The chemical structure of the substituted cyclotetraphosphazene compounds is as shown in formula I. The applicationis characterized in that at least one of the substituted cyclotetraphosphazene compounds as shown in the formula I is used as the mass spectrum calibrator for the mass spectrum calibration of variousdifferent ion sources under a positive-ion or negative-ion ionization mode. The substituted cyclotetraphosphazene compounds are good in mass spectrum response, high in sensitivity, low in isotope contribution, low in use amount, capable of avoiding the generation of a memory effect, wide in applicable m / z range, nontoxic, odorless, stable, low in cost, quite good in popularization and applicationvalue and the like.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

Mirror structure with single crystal silicon cross-member

Hydrogen cleave silicon process for light modulating mirror structure using single crystal silicon as the base cross-member. Existing processes use two critical alignment steps that can contribute to higher actuation voltages and result in lower manufacturing yields. The hydrogen cleave process simplifies the manufacturing process to one step: transferring a thin film of single crystal silicon to the CMOS substrate, resulting in minimal alignment error and providing large bonding area.

Owner:MIRADIA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com