Movable steel rail flash welding machine driven by large-power energy storage power supply device

A technology of power supply device and flash welding machine, which is applied in the direction of resistance welding equipment, welding power supply, welding equipment, etc., which can solve the problems of difficult welding operation, increased thermal load, and decreased reliability of flash welding machines, and achieves the reduction of short-circuit duration , reduce the impact load, reduce the effect of short-circuit current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

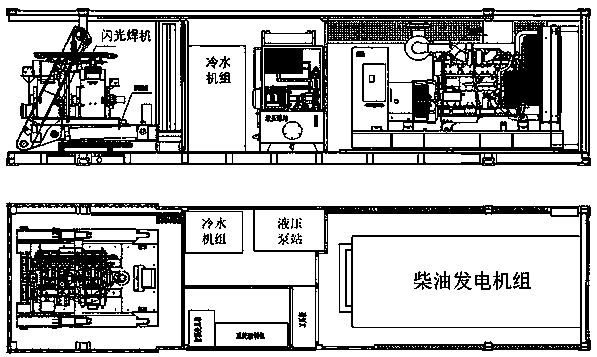

[0039] A mobile rail flash welder driven by a high-power energy storage power supply device includes a welder 9, welding machine auxiliary equipment 4 and a power supply device, the power supply device includes a battery pack power supply part and a supercapacitor pack power supply part, and the battery The power supply part of the group 1 supplies power to the power supply part of the auxiliary equipment 4 of the welding machine, and the power supply part of the super capacitor group 5 supplies power to the welding machine 9 .

[0040] When preparing for welding, the power supply part of the battery pack 1 continuously supplies power to the auxiliary system to meet the preparation conditions before welding, and the power supply part of the battery pack 1 charges the power supply part of the supercapacitor pack 5; Machine 9 supplies power.

[0041] The power supply part of the battery pack includes a charging device 10 and a battery pack 1 , the charging device 10 charges the ...

Embodiment 2

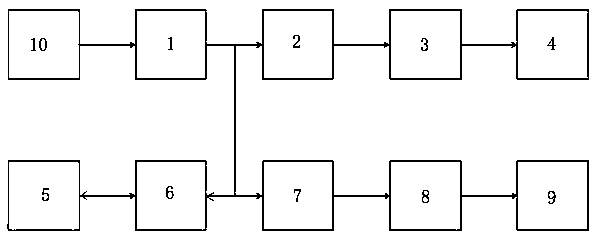

[0052] On the basis of Example 1, this application adopts a battery power supply system composed of an energy storage device and an inverter device composed of power electronics to replace a diesel generator. The energy storage device mainly realizes energy storage and release. The power supply system uses iron phosphate Lithium battery and supercapacitor 13 are combined. The inverter device mainly converts the DC power stored in the energy storage device into the single-phase AC power required by the mobile flash welding machine 9 and the three-phase power required by the auxiliary equipment. The power supply system of the welding machine 9 is mainly divided into two parts, one part is for the flash The welding machine 9 supplies power, and the other part supplies power to the hydraulic system and auxiliary systems. The system schematic diagram is as follows figure 1 shown.

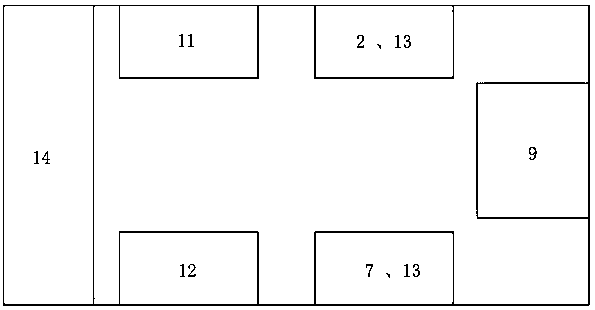

[0053] according to figure 2 Requirements, arrange the equipment according to the equipment layou...

Embodiment 3

[0056] On the basis of Examples 1 and 2, the welding process is innovated on the original rail flash welding welding process matched with the diesel generator set.

[0057] Using the flash welding machine of the present application, a mobile rail flash welding process driven by a high-power energy storage power supply device is realized. The continuous flash welding process is combined with the pulse flash welding process, and the welding current is relatively small, and the welding The load of the transformer is small, the welding time is long, the loss is low, and the heating is uniform. The welding stage includes: flashing stage, upsetting stage and pressure holding and pushing stage;

[0058] In the flash stage, the section of the weldment is rapidly melted to form a liquid bridge blast, and the joint is heated;

[0059] In the upsetting stage, excess metal at the weld is squeezed out, and plastic deformation occurs in the heat-affected zone;

[0060] In the pressure-hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com