Lithium battery anode slurry for starting power supply of motorcycle and car starting power supply and lithium battery

A technology for starting a car and positive electrode slurry, which is applied to battery electrodes, secondary batteries, circuits, etc., can solve the problems of high production costs, and achieve the effects of low production costs, long cycle life, and good safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

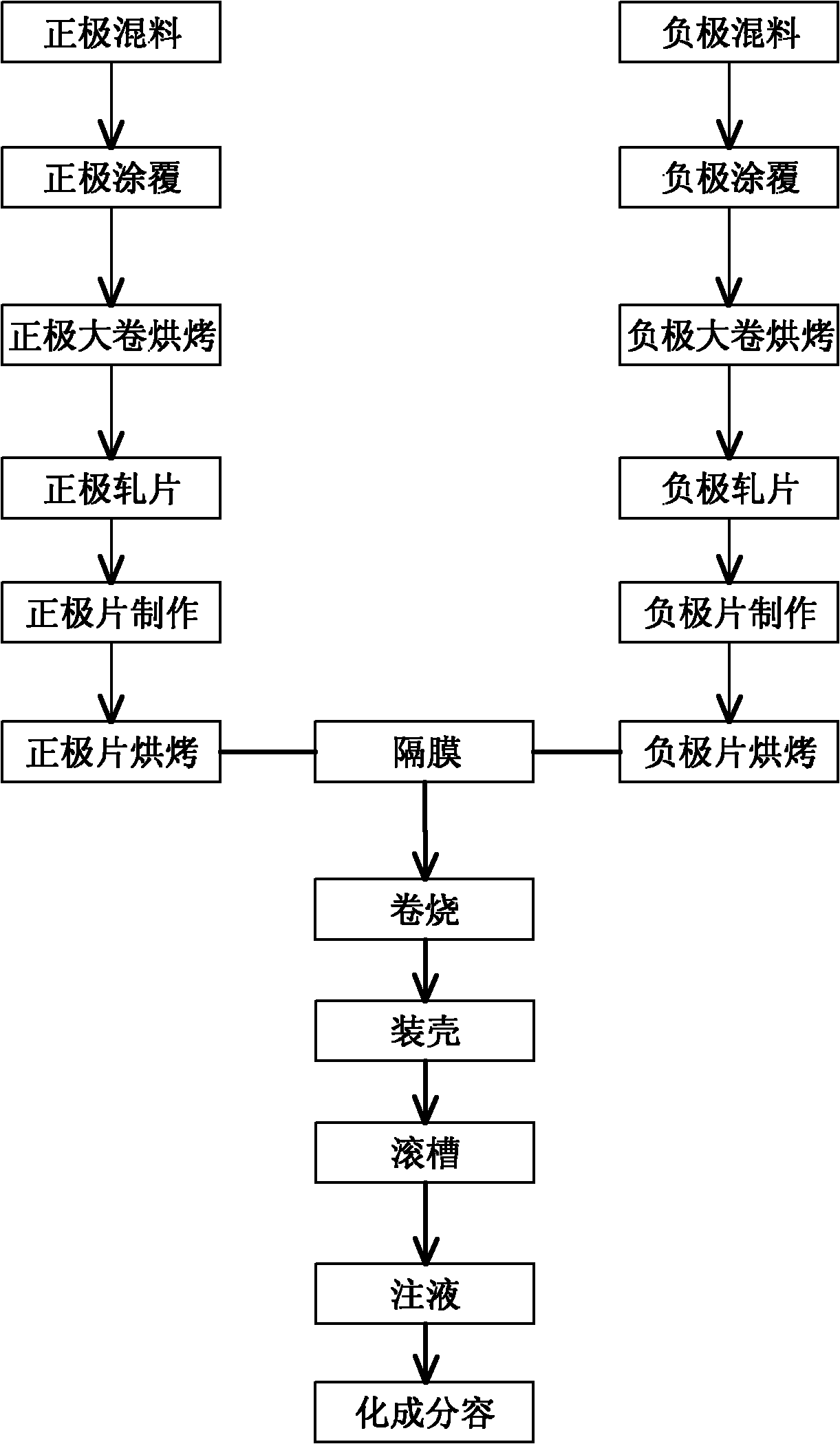

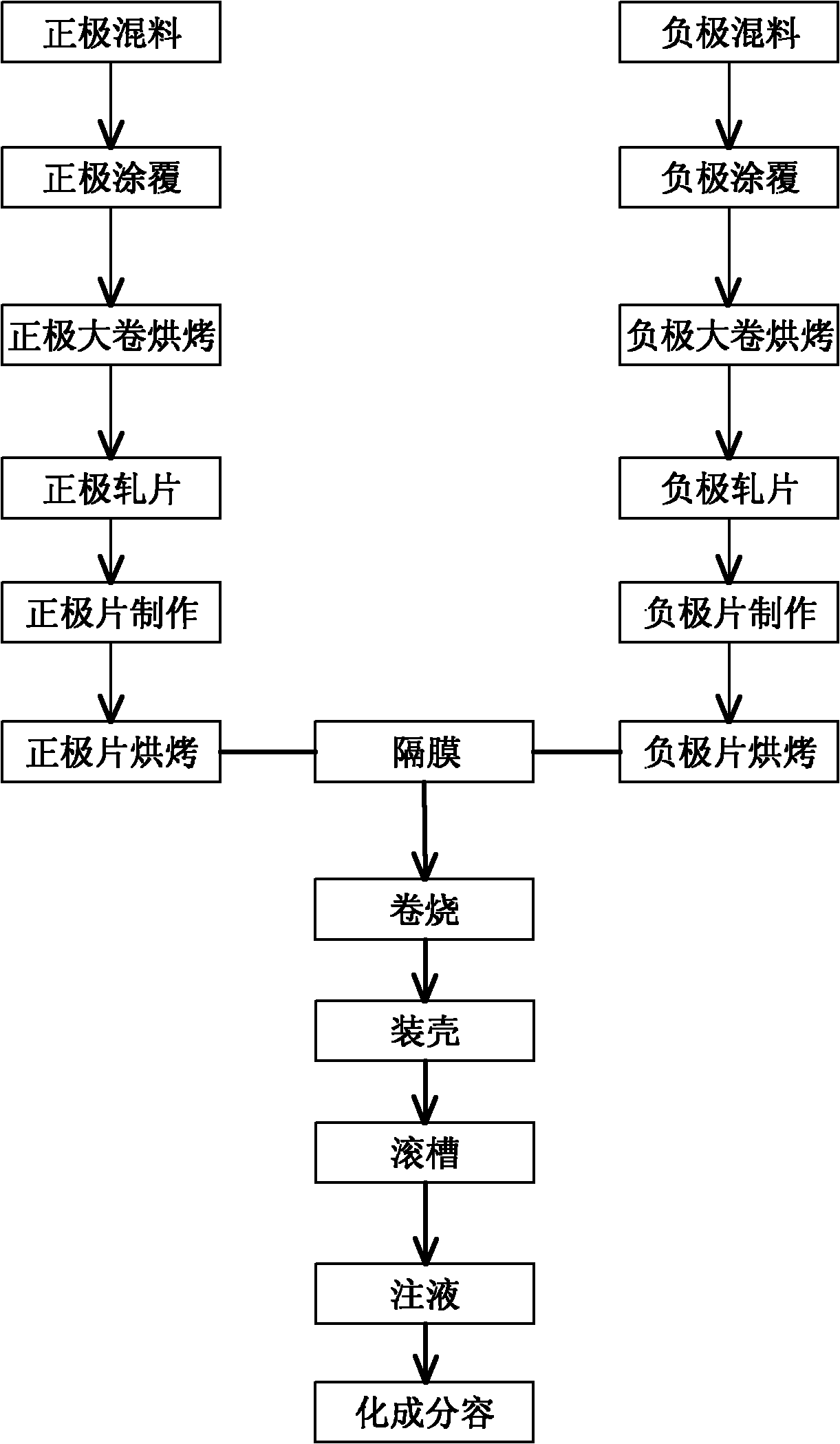

[0040] like figure 1 As shown in the flow chart of the production process for producing lithium batteries, the positive electrode material in Example 1 in Table 1 was stirred and mixed for 5 to 10 hours. After mixing, the viscosity of the positive electrode slurry was 3500±500mPaS, and the particles of the positive electrode slurry were less than 150 mesh . Stir and mix the negative electrode material according to Example 1 in Table 2 for 5-10 hours. After mixing, the viscosity of the negative electrode slurry is 1500±500 mPaS, and the particles of the negative electrode slurry are less than 120 mesh.

[0041] Select a pure aluminum foil with a thickness of 0.018±0.002mm and a length×width of (1450±2)×(56.5±0.2)mm, use an oven to evaporate the solvent of the positive electrode slurry after mixing, and then heat it at a constant temperature of 20°C Coated on pure aluminum foil, the coating surface density is 1.25±0.020g / 100cm 2 . Select a double-gloss copper foil with a thic...

Embodiment 2~5

[0048] Mix according to the positive electrode materials of Examples 2-5 in Table 1 and the negative electrode materials of Examples 2-5 in Table 2, and the other process flow is the same as that of Example 1, and will not be repeated.

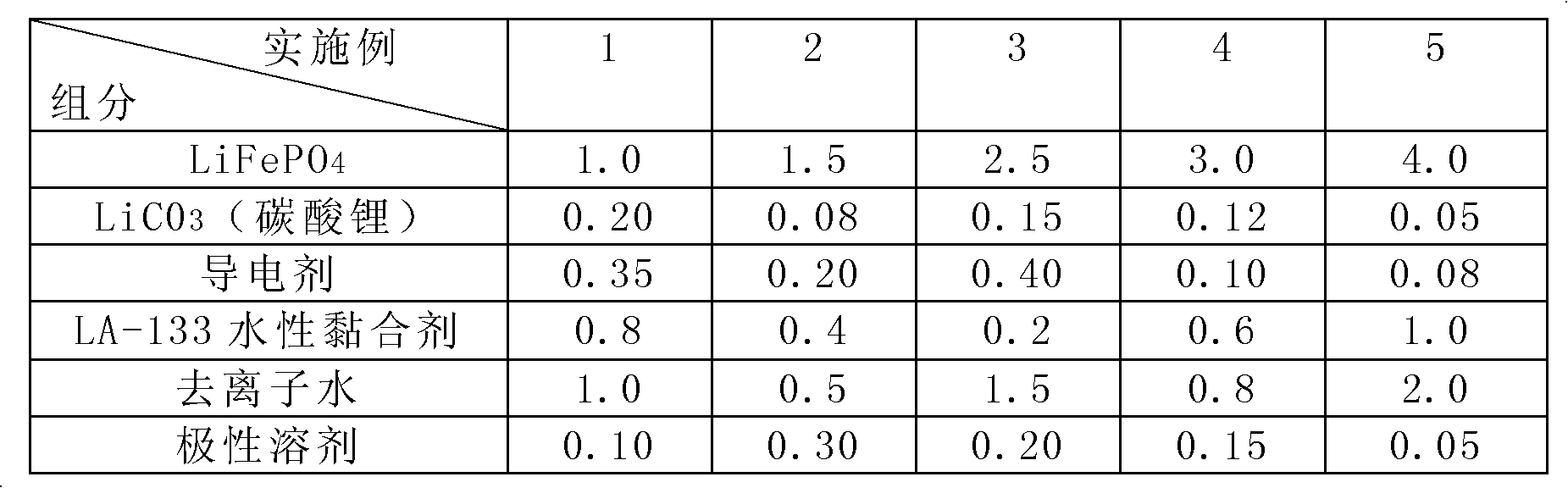

[0049] Table 1: The positive electrode material weight ratio (kg) of the lithium batteries of Examples 1-5

[0050]

[0051] Wherein the conductive agent described in Example 1 is conductive carbon black; the polar solvent is N-methylpyrrolidone.

[0052] The conductive agent described in embodiment 2 is flake graphite; the described polar solvent is dimethylformamide.

[0053] The conductive agent described in Example 3 is conductive carbon black and flake graphite, and the weight ratio between the two is 6:4; the polar solvent is N-methylpyrrolidone.

[0054] The conductive agent described in Example 4 is conductive carbon black and flake graphite, and the weight ratio between the two is 5:5; the polar solvent is dimethyl sulfoxide.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com