Trace nitrogen isotope analysis system and method

An analysis system and nitrogen isotope technology, applied in the analysis system of trace nitrogen isotopes, the field of trace nitrogen isotope analysis, can solve the problems of cumbersome experimental process, sample loss, small analysis error, etc., achieve simple and controllable process, reduce detection limit, Analysis of the effect of small errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example S-I

[0101] Preparation of a sample collection tube encapsulating a gaseous sample containing nitrogen to be measured

[0102] Place the capillary in the atmosphere of the gaseous sample to be tested at 20°C for 5 hours, and then use a liquefied gas torch to heat the two ends of the capillary to melt and seal the two ends of the capillary, so as to obtain the sealing of the two ends of the gaseous sample to be tested containing nitrogen. A capillary sample collection tube with a length of 5-8cm, an outer diameter of 1-2mm, and a wall thickness of 0.1-0.2mm is ready for use.

preparation example S-II

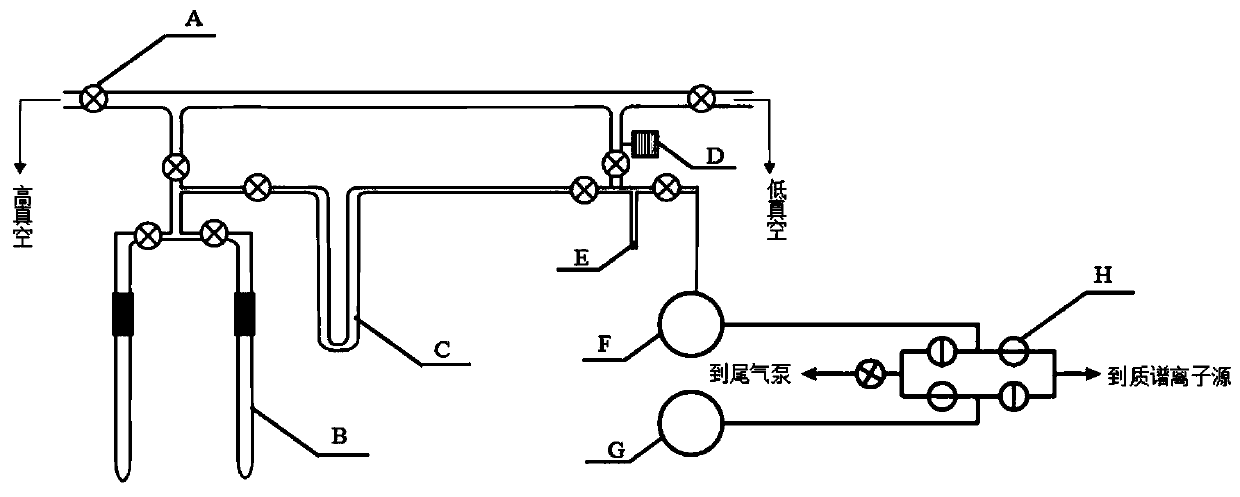

[0104] Preparation of a sample collection tube encapsulating a gaseous sample to be tested obtained by carrying out a nitrogen element transfer reaction on a solid sample to be tested containing nitrogen

[0105] Put the solid sample, 100mg copper wire and 150mg copper oxide wire into a quartz tube with a flat mouth and a round bottom, the top of the quartz tube is provided with a sealing joint and a vacuum gauge, and then the quartz tube is connected to the vacuum pipeline through the sealing joint. The quartz tube is vacuumized, and the quartz tube is heated to 150°C during the vacuuming process, and the vacuum degree in the quartz tube reaches 1×10 -4 Pa, use a liquefied gas torch to heat below the connection of the quartz tube and the sealing interface of the vacuum pipeline, and the distance from the connection is 10-20% of the total length of the quartz tube to make it melt and seal, thereby obtaining A sample collection tube with both ends of the sealed solid sample con...

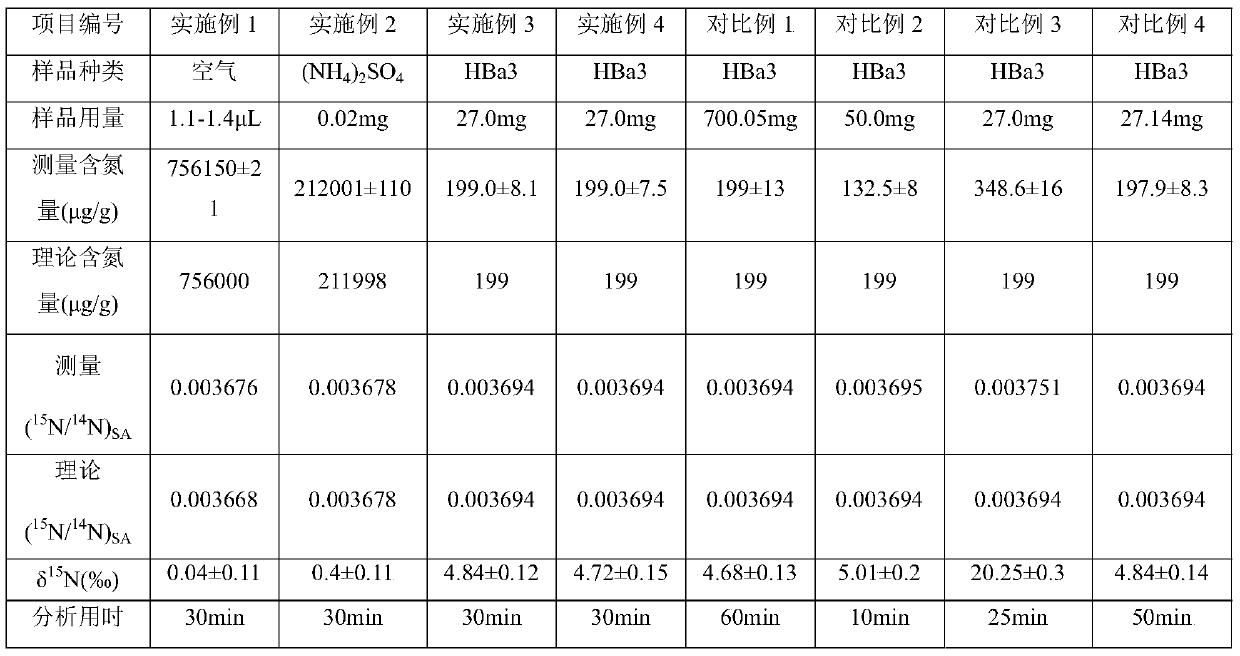

Embodiment 1

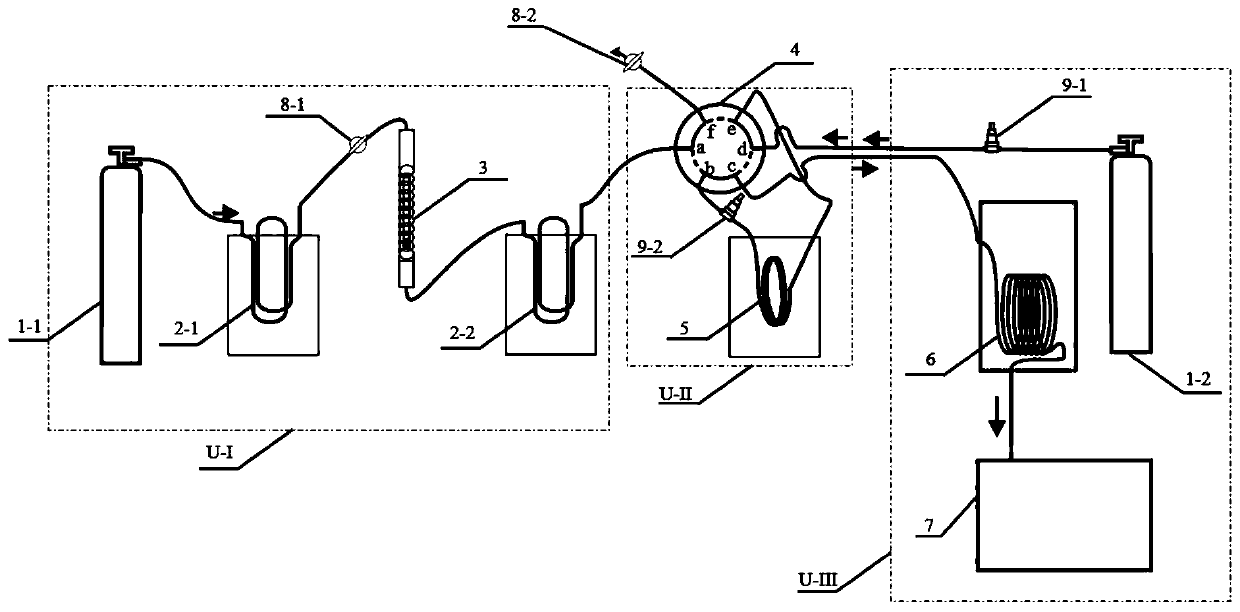

[0107] (i) press figure 1 The connections shown were used to assemble the trace nitrogen isotope analysis system.

[0108] The analysis system includes: primary purification unit U-I, control unit U-II and secondary purification sampling unit U-III, wherein the primary purification unit U-I, control unit U-II and secondary purification sampling unit U- III is sequentially connected through the connecting pipeline; wherein, the control unit U-II and the secondary purification sampling unit U-III are pre-vacuumized before being connected to the system,

[0109] The primary purification unit U-I includes: a first carrier gas cylinder 1-1, a first cold trap 2-1, a ripple breaker 3 and a second cold trap 2-2 connected in sequence, wherein the first carrier gas Bottle 1-1 is a high-purity helium (99.999% by volume) bottle, and 5A molecular sieve 1-2g is filled in the first cold trap 2-1;

[0110] The secondary purification sampling unit U-III includes: the second carrier gas bottl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com