Propane complete oxidation catalyst as well as preparation method and application thereof

A technology of complete oxidation and catalyst, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

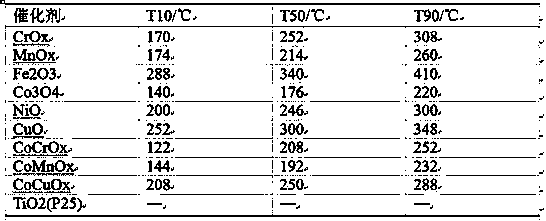

Examples

Embodiment 1

[0016] Weigh 3.18g of Na 2 CO 3 Dissolve in 30mL deionized water to prepare 1mol / L Na 2 CO 3 Solution; Weigh 8.00g of Cr(NO 3 ) 3 9H 2 Dissolve O in 20mL deionized water to prepare 1mol / L chromium solution; drop the chromium solution into the alkali solution drop by drop, react in a water bath at 50°C for 1h, wash with deionized water until neutral, dry at 100°C, and roast at 300°C for 3h. CrO x .

Embodiment 2

[0018] Weigh 2.12g of Na 2 CO 3 Dissolve in 20mL deionized water to prepare 1mol / L Na 2 CO 3 Solution; 7.16g 50% mass fraction of Mn(NO 3 ) 2 Dilute the solution to 20mL 1mol / L manganese solution; drop the manganese solution into the alkali solution drop by drop, react in a water bath at 50°C for 1h, wash with deionized water until neutral, dry at 100°C, and roast at 300°C for 3h to obtain MnO x .

Embodiment 3

[0020] Weigh 3.18g of Na 2 CO 3 Dissolve in 30mL deionized water to prepare 1mol / L Na 2 CO 3 Solution; Weigh 8.08g of Fe(NO 3 ) 3 9H 2 Dissolve O in 20mL deionized water to prepare 1mol / L iron solution; drop the iron solution into the alkali solution drop by drop, react in a water bath at 50°C for 1h, wash with deionized water until neutral, dry at 100°C, and roast at 300°C for 3h. Get Fe 2 o 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com