Metal catalyst preparation method and preparation method of carbon nanotube

A metal catalyst, carbon nanotube technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical elements of heterogeneous catalysts, etc., can solve the problem of inconsistent particle size and affect the quality of carbon nanotubes , low yield of metal catalysts, etc., to achieve the effect of uniform particle size, low production cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention discloses a method for preparing a metal catalyst, comprising the following steps:

[0033] Step 1: provide a kind of metal salt solution, in described metal salt solution, be dissolved with leavening agent, carrier metal and active metal ion with carbon nanotube preparation catalysis, described leavening agent comprises organic acids, organic alcohols , one or more of organic aldehydes, nitrogen-containing organic compounds, and sugars;

[0034] Step 2: adding a precipitating agent into the metal salt solution, and stirring to obtain composite metal precipitation;

[0035] Step 3: Precipitating the composite metal and calcining at elevated temperature, cooling down after calcining, and sieving to obtain a metal catalyst.

[0036] When preparing the metal salt solution, take the active metal salt and the carrier metal salt according to the proportion of the catalyst components, dissolve them in deionized water, and filter to obtain the first solution; tak...

Embodiment 1

[0055] This embodiment is used to illustrate the preparation method of the metal catalyst disclosed in the present invention and its carbon nanotubes, comprising the following steps:

[0056] Step 1: Configure metal salt solution, weigh Fe(NO 3 ) 3 ·6H 2 O, Mg(NO 3 ) 2 ·6H 2 O, La(NO 3 ) 3 ·6H 2 O, and dissolving it in deionized water, adding 5% sucrose by total weight, stirring, after the metal salt and sucrose are all dissolved, filtering impurities to obtain a metal salt solution;

[0057] Step 2: Add ammonia water to the metal salt solution to carry out catalyst precipitation, and NH in the ammonia water 3 ·H 2 The amount of the substance of O is equal to the total number of charges of metal cations in the metal salt solution, the pH value is adjusted to 10, and the composite metal precipitation is obtained by stirring, and the stirring speed is 2000 rpm;

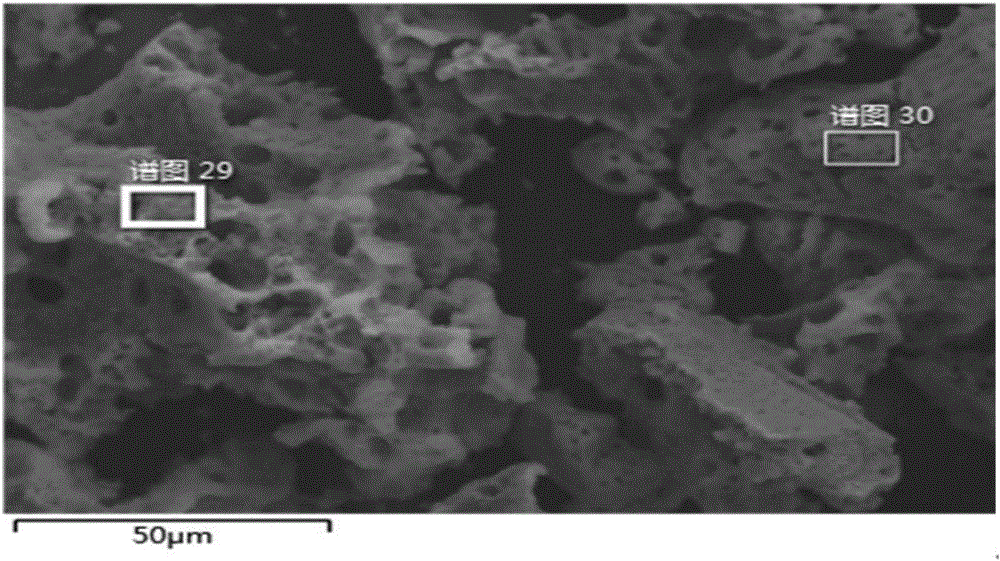

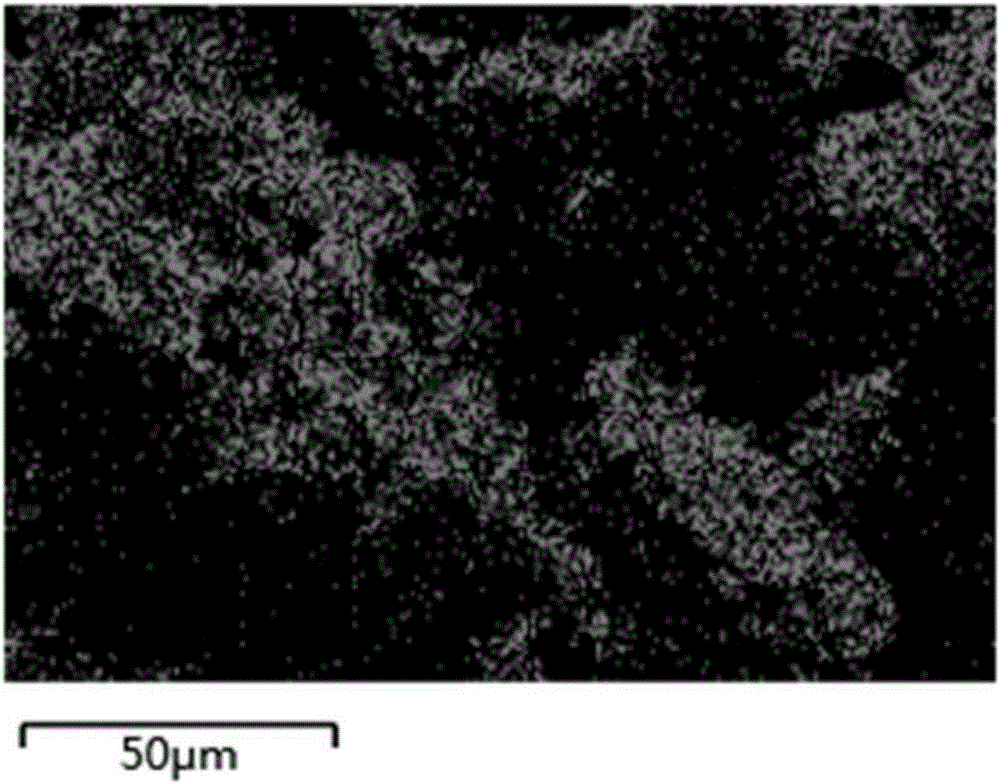

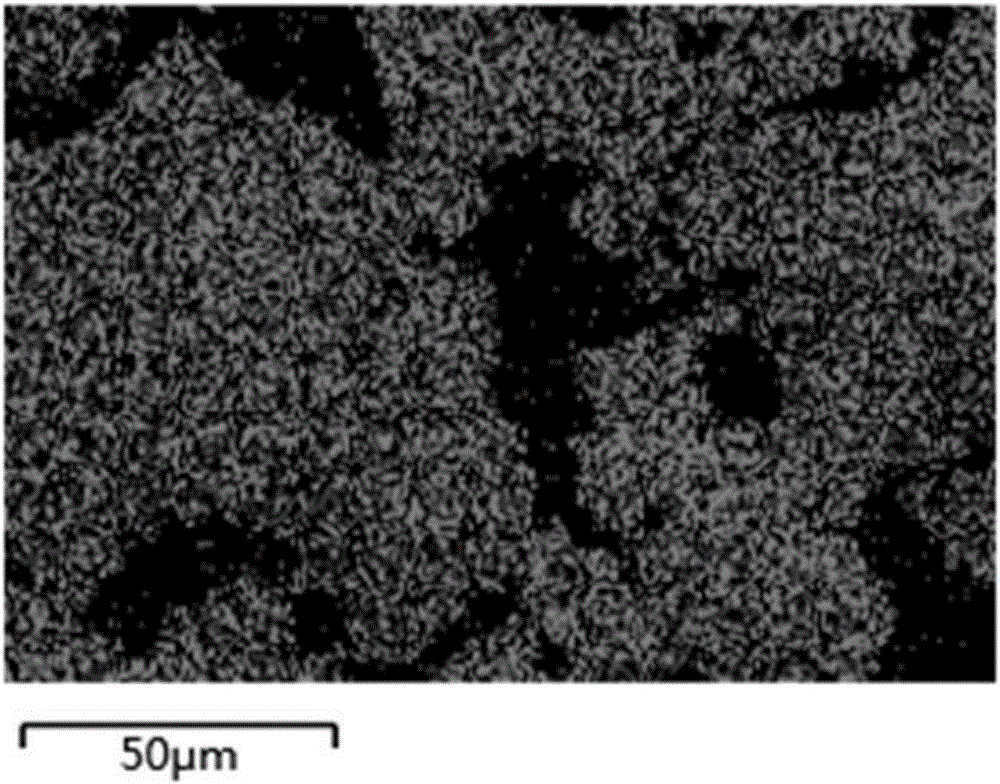

[0058] Step 3: Put the prepared composite metal precipitate together with the metal salt solution into a mu...

Embodiment 2

[0062] This embodiment is used to illustrate the preparation method of the metal catalyst disclosed in the present invention and its carbon nanotubes, comprising the following steps:

[0063] Step 1: Prepare metal salt solution, weigh Ni(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 ·6H 2 O, La(NO 3 ) 3 ·6H 2 O, and dissolving it in deionized water, adding 5% sucrose by total weight, stirring, after the metal salt and sucrose are all dissolved, filtering impurities to obtain a metal salt solution;

[0064] Step 2: Add ammonia water to the metal salt solution to carry out catalyst precipitation, and NH in the ammonia water 3 ·H 2 The amount of the substance of O is equal to the total number of charges of metal cations in the metal salt solution, the pH value is adjusted to 10, and the composite metal precipitation is obtained by stirring, and the stirring speed is 2000 rpm;

[0065] Step 3: Put the prepared composite metal precipitate together with the metal salt solution into a muff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com