Automatic control method and apparatus for delivering medicine to process heavy metal ion containing wastewater

A heavy metal ion and control method technology, applied in the field of environmental protection industrial wastewater treatment, can solve the problems of difficult dosing control process, manual quantitative dosing, heavy metal ion concentration, etc., and achieve continuous and stable dosing automatic control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

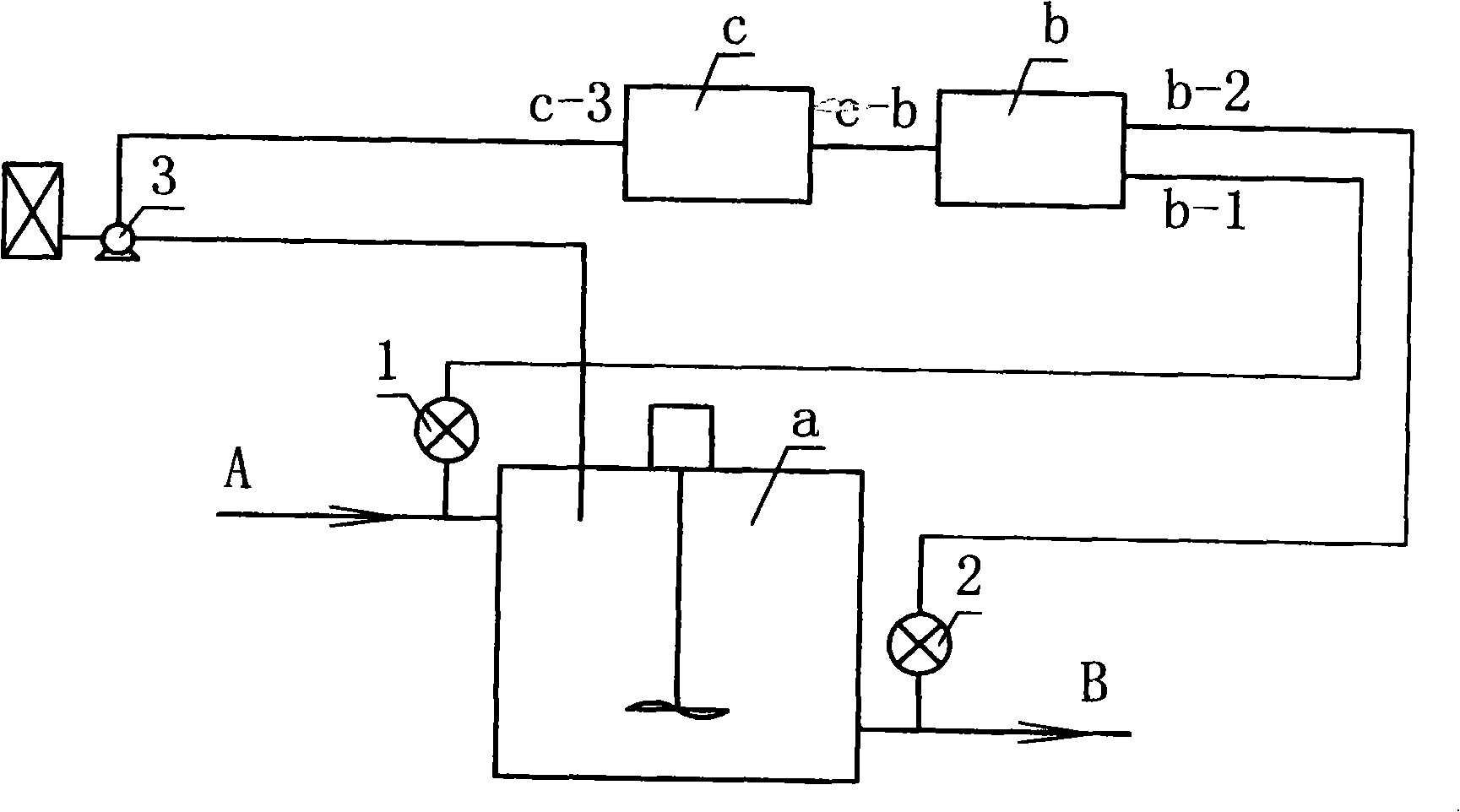

[0026] The mathematical operator (subtractor) and PID adjustment controller are selected to realize the control function. The wastewater A containing one or more heavy metal ions adjusted to the required pH value of the precipitation reaction is introduced into the precipitation reaction device a; before the precipitation reaction device a, the ORP1 value before the precipitation reaction occurs is detected by the online ORP instrument 1, and the corresponding output 4 -20mA signal b-1 to the mathematical operator (subtractor) b; after the precipitation reaction device a, the ORP2 value after the precipitation reaction occurs is detected by the online ORP instrument 2, and the corresponding output 4-20mA signal b-2 is sent to the mathematical operator (subtractor) b; output 4-20mA signal c-b to the PID adjustment controller c after performing difference calculation by the mathematical operator (subtractor) b; on the PID adjustment controller, dosing according to the heavy metal...

Embodiment 2

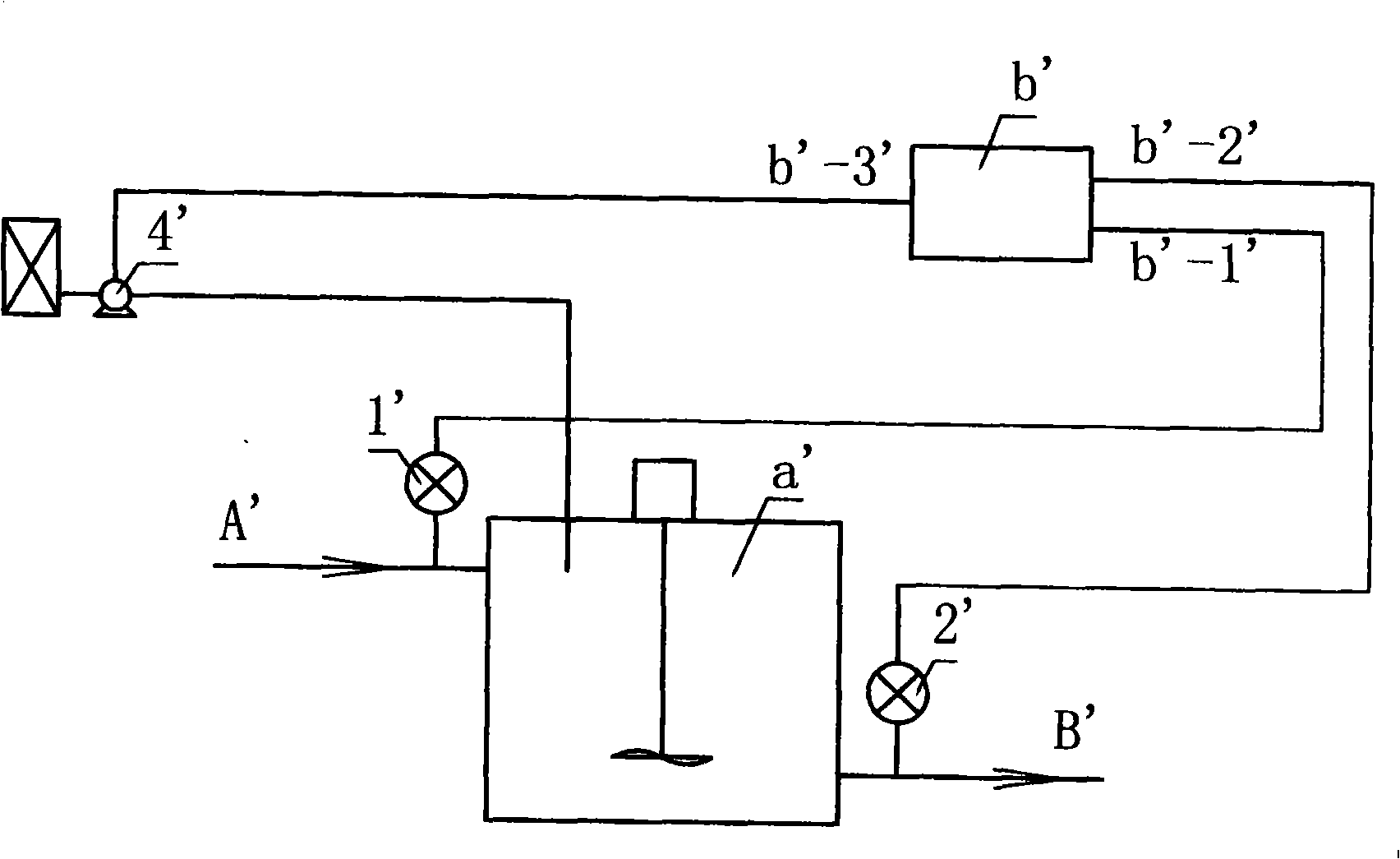

[0028] The PLC programmable controller is selected to realize the control function. The wastewater A containing one or more heavy metal ions adjusted to the required pH value of the precipitation reaction is introduced into the precipitation reaction device a; the ORP1 value before the precipitation reaction occurs is detected by the online ORP instrument 1' before the precipitation reaction device a', and the corresponding Output 4-20mA signal b'-1' to PLC programmable controller b'; after the precipitation reaction device a', the ORP2 value after the precipitation reaction is detected by the online ORP instrument 2', and correspondingly output 4-20mA signal b' -2' to PLC programmable controller b'; the corresponding 4-20mA signal b'-3' is obtained after the PLC programmable controller b' performs difference calculation on b'-1' and b'-2'; On the PLC programmable controller b', set the 4-20mA output signal c-3 control value according to the heavy metal precipitation agent dos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com