Device and method for reducing low-temperature smoke particulate matter emission in cold procedure of sinter ring

A technology of low-temperature flue gas and sintering ring cooler, which is applied in the direction of steam engine installation, process efficiency improvement, lighting and heating equipment, etc. It can solve the problems that cannot meet the national pollutant discharge standards continuously and stably, and achieve the reduction of dust pollution, The effect of reducing investment and maintenance costs and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

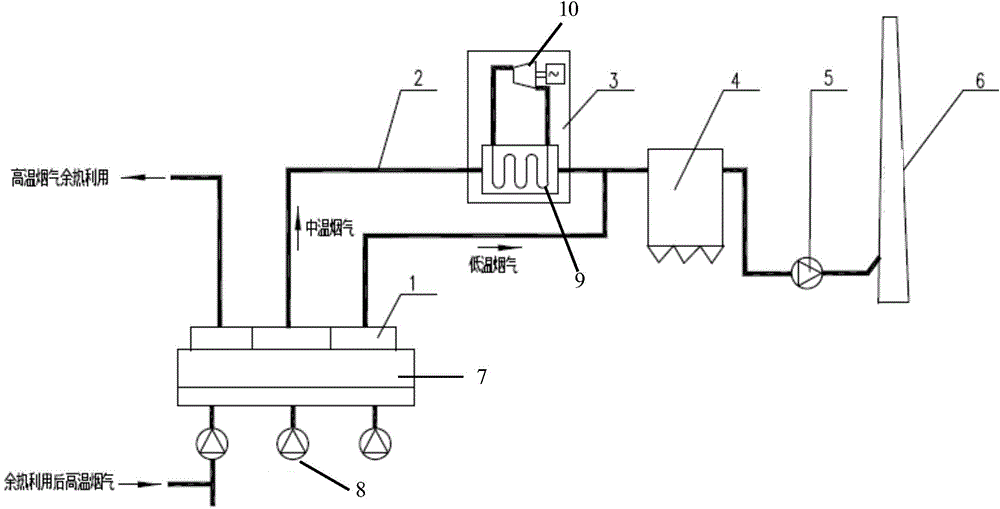

[0027] The medium-temperature flue gas with an average temperature of 171°C produced by the annular cooler is mixed with the low-temperature flue gas with an average temperature of 87°C generated by the annular cooler and enters the normal temperature bag filter, and passes through the bag filter The particulate matter concentration in the purified exhaust gas is 15mg / m 3 .

Embodiment 2

[0029] The medium-temperature flue gas with an average temperature of 195°C produced by the annular cooler is mixed with the low-temperature flue gas with an average temperature of 97°C generated by the annular cooler and enters the normal temperature bag filter, and passes through the bag filter The particulate matter concentration in the purified exhaust gas is 19.2mg / m 3 .

[0030] The invention makes full use of the waste heat of the sintering ring cooling medium and low temperature flue gas that is directly discharged into the atmosphere at present, reduces the temperature of the flue gas, makes it possible to directly carry out the condition of high-efficiency bag dust removal at room temperature, and uses the bag dust collector to remove the dust in the flue gas Particles, greatly eliminating the dust in the flue gas from polluting the environment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com