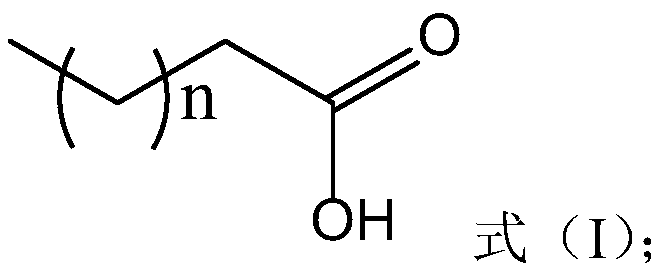

Method for extracting metal ions from fatty acids

A technology of metal ions and rare earth metal ions, which is applied in the direction of improving process efficiency, can solve problems such as pollution, difficult operation, and low extraction rate of metal ions, and achieve the effects of good biocompatibility, easy transportation, and easy degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The ionic rare earth ore was taken from an ionic rare earth mine in Ganzhou, Jiangxi. The total amount of rare earth REO contained in the sample was 0.114%. Take 100g of the dried ionic rare earth ore sample and put it into the leaching column, and dissolve 0.353g of yttrium chloride in 100mL to remove In ionized water, adjust the pH value to 4-5, leach the rare earth ore in the leaching column with the prepared leaching solution, then rinse once with 50mL deionized water, and collect the leaching solution. The rare earth leaching rate obtained in this embodiment is 95%, and the ammonium sulfate leaching rate is 98% under the same conditions. Then, 3.58 g of lauric acid was ground and saponified using 2.9 mL of 5 mol / L sodium hydroxide at room temperature, and the degree of saponification of lauric acid was 80%. Mix the saponified lauric acid with the rare earth leaching solution at room temperature and fully stir for 10 minutes. After precipitation, solid-liquid separa...

Embodiment 2

[0049] The ionic rare earth ore is taken from an ionic rare earth mine in Ganzhou, Jiangxi. The total amount of REO contained in the sample is 0.114%. Take 100g of the dried ionic rare earth ore sample and put it into the leaching column, and dissolve 0.439g of lanthanum chloride in 100mL to remove In ionized water, adjust the pH value to 4-5, leach the rare earth ore in the leaching column with the prepared leaching solution, then rinse once with 50mL deionized water, and collect the leaching solution. The rare earth leaching rate obtained in this embodiment is 96%. Then, 3.58 g of lauric acid was ground and saponified using 2.9 mL of 5 mol / L sodium hydroxide at room temperature, and the degree of saponification of lauric acid was 80%. Mix the saponified lauric acid with the rare earth leaching solution at room temperature and fully stir for 10 minutes. After precipitation, solid-liquid separation is carried out to obtain the rare earth precipitate and the water phase. After ...

Embodiment 3

[0051] Grinding and saponifying 6.9g of palmitic acid with 4.3mL of 5mol / L sodium hydroxide at room temperature, the degree of saponification of palmitic acid is 80%. The rare earth leaching solution is taken from a rare earth mine in Longyan, Fujian. The composition of the rare earth leaching solution is: total concentration of rare earth It is 0.5g / L, pH=5.3, and the volume is 2L. It also contains aluminum ions and calcium ions. The specific components are shown in Table 1. The ratio of rare earth elements in the rare earth leaching solution is shown in Table 2.

[0052] Table 1. The composition of the rare earth leachate used in Example 4 of the present invention

[0053] Element total rare earth Aluminum ion calcium ion Concentration, g / L 0.5 0.00088 0.00056

[0054] Mix the saponified palmitic acid with the rare earth leaching solution at room temperature and fully stir for 10 minutes. After precipitation, separate the solid and liquid to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com