Method of recovery of metals from etching solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

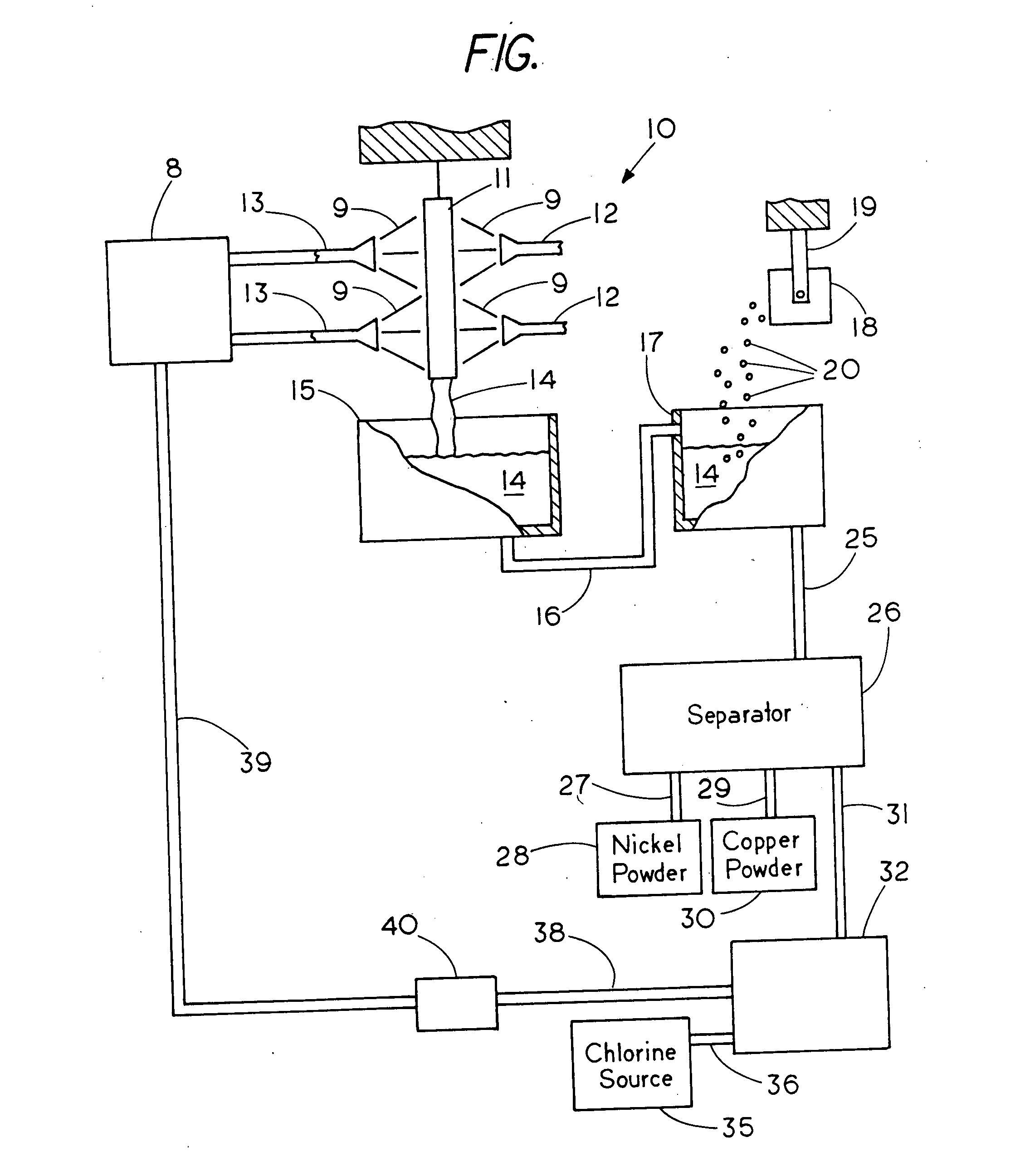

[0009] The FIGURE shows an etchant regeneration system 10 comprising a first etching stage wherein an article 11 is subjected to a spray of etching solution 9 from a set of spray nozzles 12 and 13. The fresh etching solution, which is contained in a container 8, is directed onto the article 11 though a set of spray nozzles 12 that direct etchant on one side of article 11 and a second set of spray nozzles 13 direct etchant on the other side of article 11. Although spray etching is shown, other etching techniques such as immersion of the article in the etching solution 9 can be used. The etching solution 9 removes unwanted material from the article, which is then carried away by the spent etching solution 14. The spent etching solution 14 and the unwanted material is then collected in a container 15.

[0010] In the etching of metals, a common etchant such as ferric chloride (FeCl3) is used as the etching solution. The removal of the metal from the article leaves a spent etching solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com