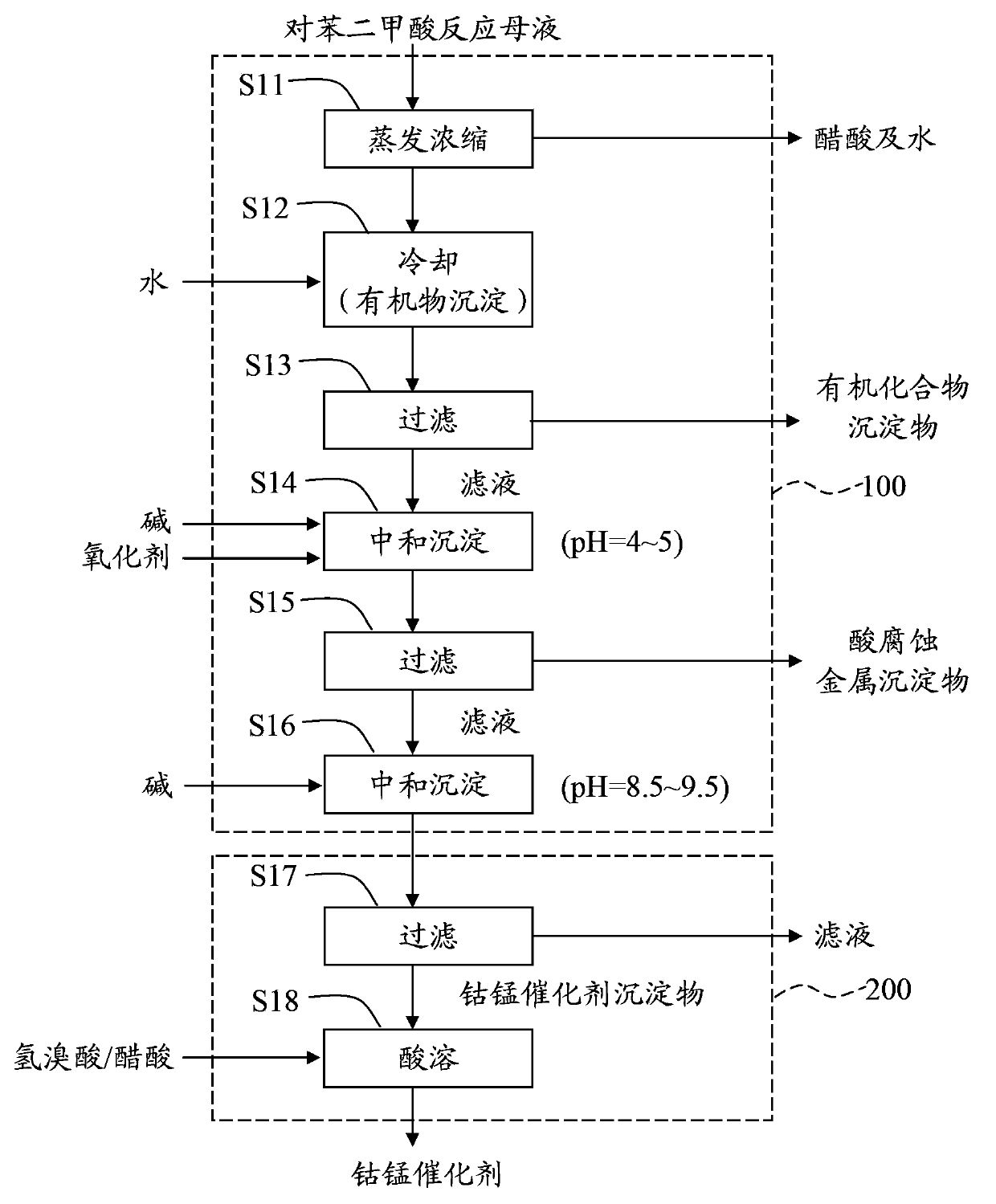

Method for recovering cobalt manganese catalyst from terephthalic acid reaction mother solution

A technology for recovery of terephthalic acid and mother liquor, applied in chemical instruments and methods, catalyst regeneration/reactivation, physical/chemical process catalysts, etc., can solve problems such as methods for recycling cobalt and manganese catalysts that have not been seen, Achieve the effect of lightening the load and simplifying the processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0072] Below, utilize embodiment to carry out more specific description to the present invention, but the present invention is not limited to following embodiment:

[0073] Take 1000L of reaction mother liquor, which contains 96% acetic acid and water, 4% organic compounds, trace acid corrosion metal ions, and 400ppm cobalt ions and 400ppm manganese ions.

[0074] The reaction mother liquor is added to the evaporation tank in batches for evaporation and concentration, and the solution temperature at the bottom of the evaporation tank is gradually raised to 200°C, and the reaction mother liquor is evaporated and concentrated to 100L to form a concentrated slurry.

[0075] Add the concentrated slurry to 1000L of cold water at 20°C. At this time, a precipitate is formed to form a suspension, and then the suspension is cooled to 20°C. After waiting for 10 minutes, most of the organic compounds in the suspension have been precipitated. The suspension is then filtered and washed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com