Heavy-metal-polluted site soil leaching remediation method and device

A technology of soil rinsing and remediation method, which is applied in the field of contaminated soil remediation, can solve problems such as limited application, and achieve the effect of remediating site soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

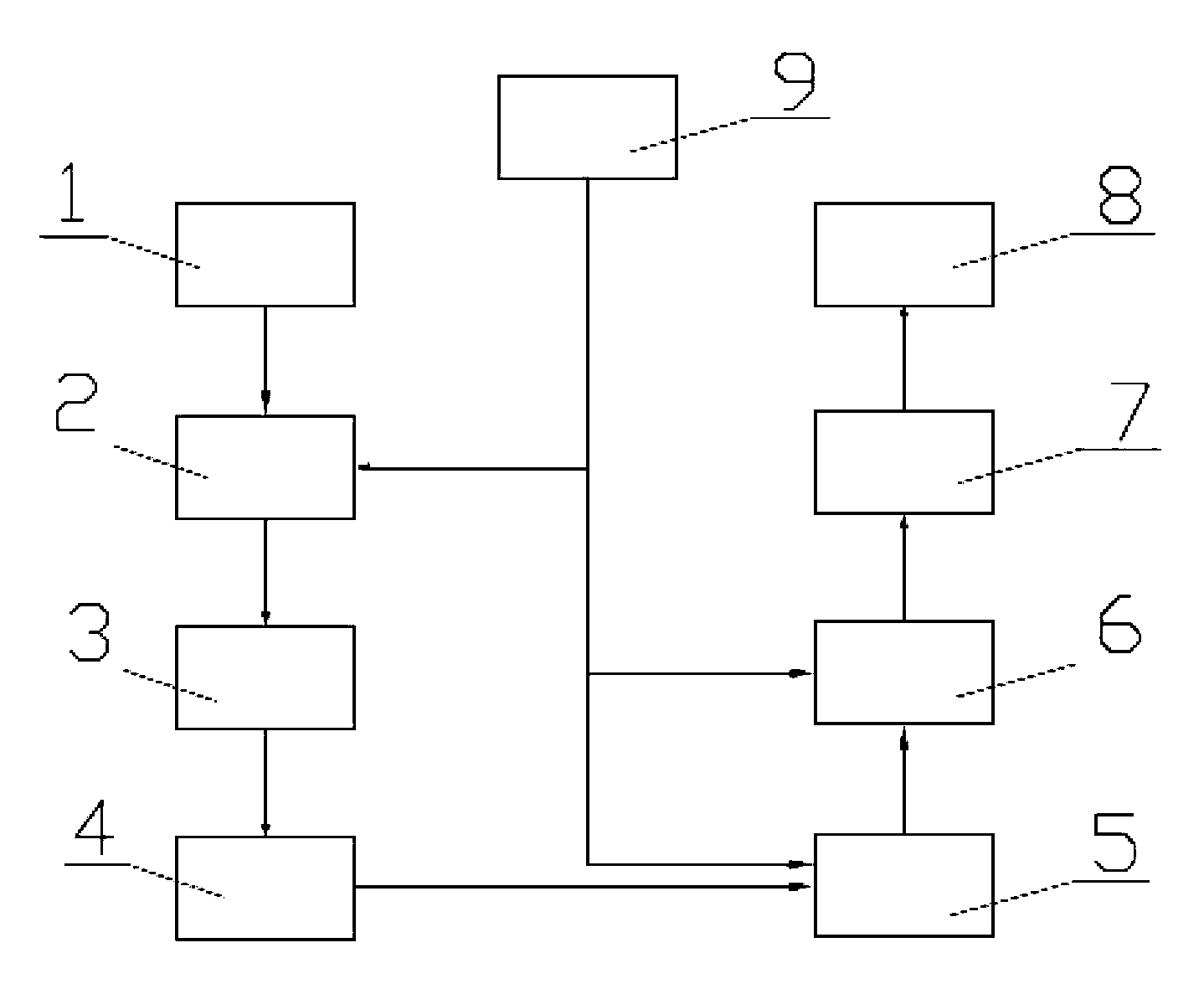

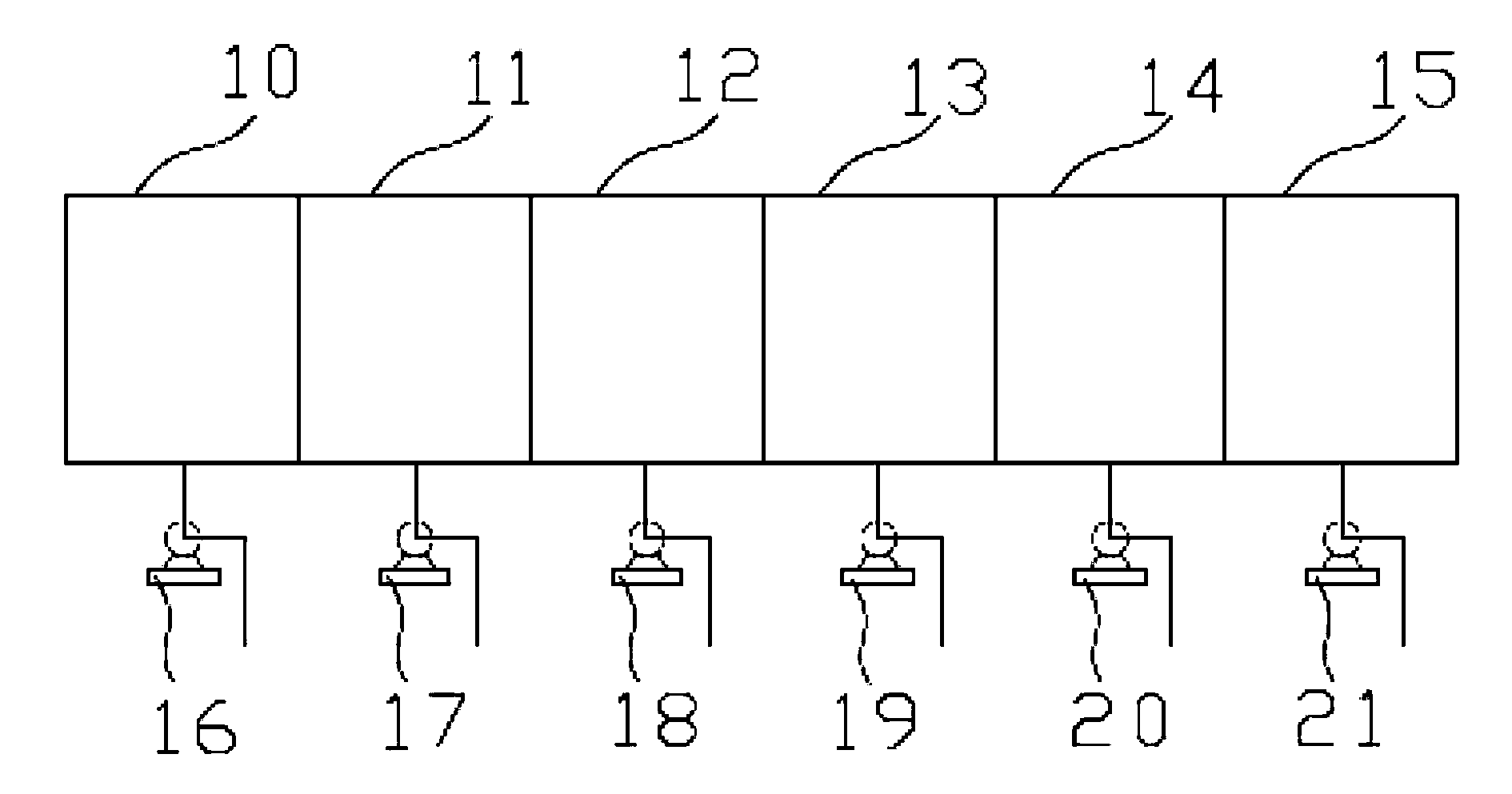

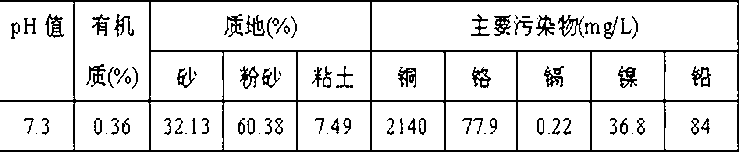

[0034] See figure 1 In this embodiment, the heavy metal contaminated site soil leaching repair equipment includes: soil conveyor 1, leaching reaction tank (with feed grid and mechanical stirring system) 2, trommel screen 3, hydrocyclone separator (with feed slurry pump) 4, heavy metal precipitation reaction tank 5, coagulation sedimentation tank 6, plate and frame filter press 7, reclaimed water storage tank 8 and dosing system 9. The above-mentioned main component units can be disassembled and assembled separately. The soil conveyor 1 transports the excavated soil to the leaching reaction tank 2 through the mechanical belt transmission mode; Large impurities and stones are separated, and a mechanical stirring system and a pH meter are prepared at the same time. The discharge port at the bottom of the leaching reaction tank 2 transports the processed materials to the trommel 3 processing unit under the action of gravity for separation of large particles of soil. The mud liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com