Liquid-phase CO2 fracturing fluid

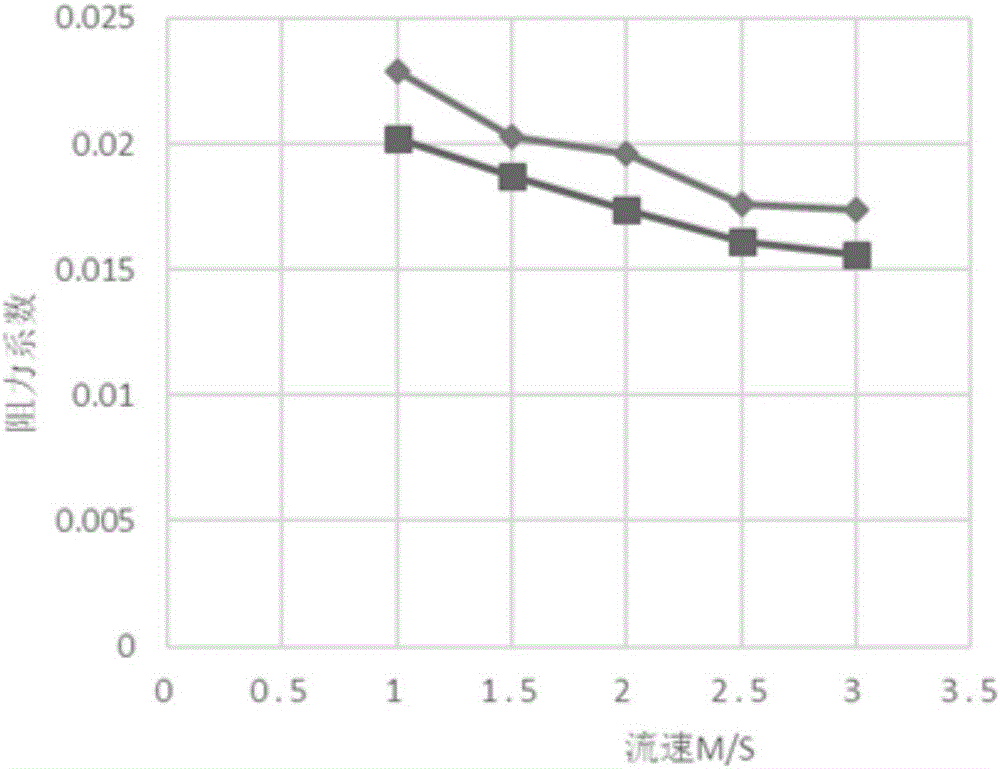

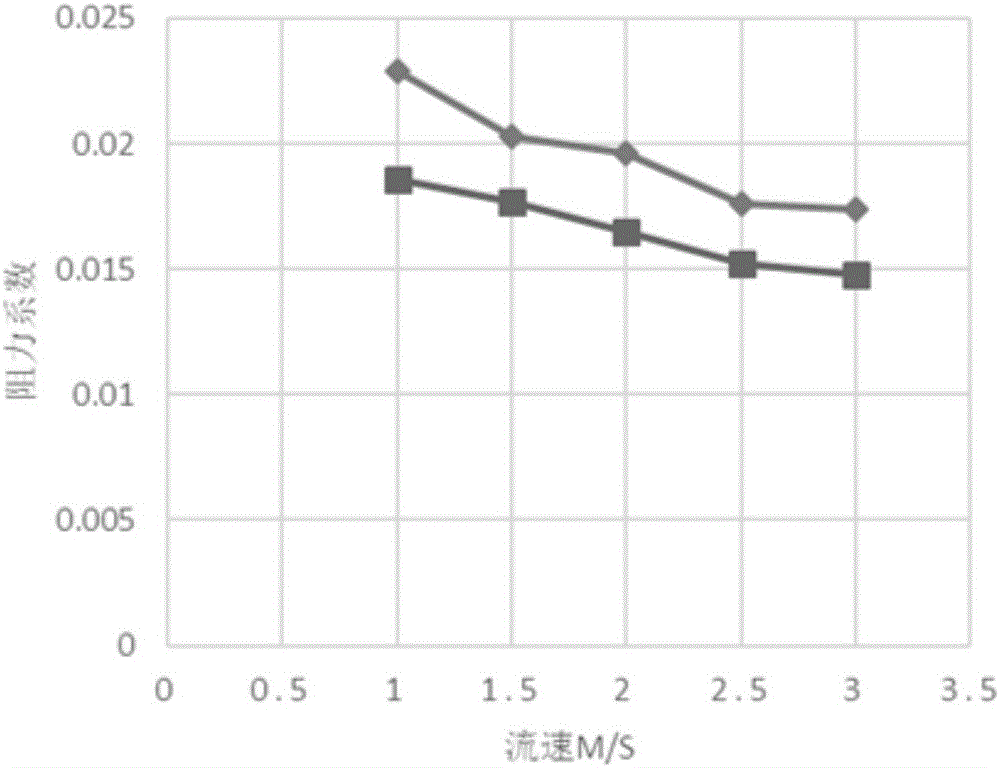

A technology of liquid carbon dioxide and fracturing fluid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of high friction and high friction that cannot be widely used, so as to improve sand-carrying performance, slow down settlement rate, The effect of changing the mode of settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

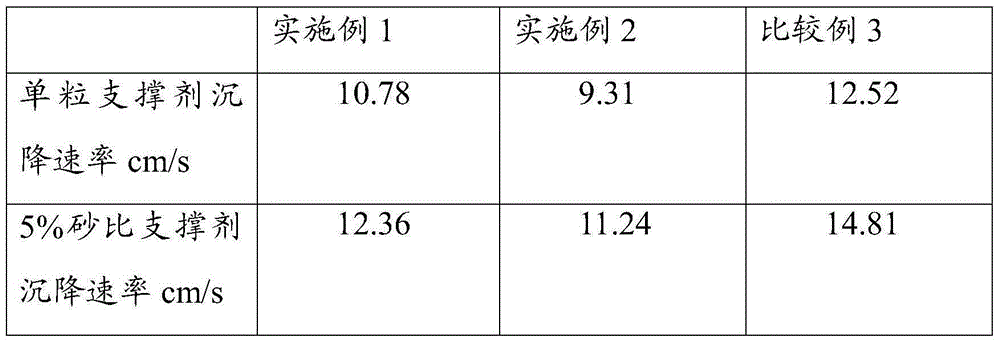

Embodiment 1

[0041] Example 1: Cool carbon dioxide to -10°C indoors, pressurize to 25Mpa, take 2% tackifier, 5% auxiliary solvent, and 0.05% nano-coated fibers and add them to 92.95% liquid carbon dioxide through a closed injection device, and stir It is dissolved and formulated into a liquid carbon dioxide fracturing fluid system.

Embodiment 2

[0042] Embodiment 2: In the room, carbon dioxide is cooled to -10°C, pressurized to 25Mpa, gets 2% tackifier, 5% auxiliary solvent, 0.1% nano-coated fiber and adds it to 92.9% liquid carbon dioxide through airtight injection equipment, stir It is dissolved and formulated into a liquid carbon dioxide fracturing fluid system.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com