Foundation reinforcement and inclination correction method for friction piles of high-rise building

A high-rise building and foundation reinforcement technology, which is applied in construction, building maintenance, building construction, etc., can solve problems such as secondary settlement, secondary damage of the upper structure of the building, and changes in the bearing capacity of the foundation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

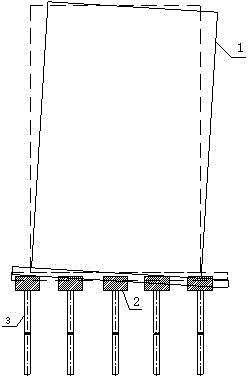

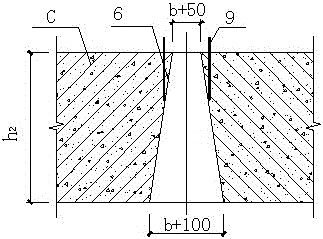

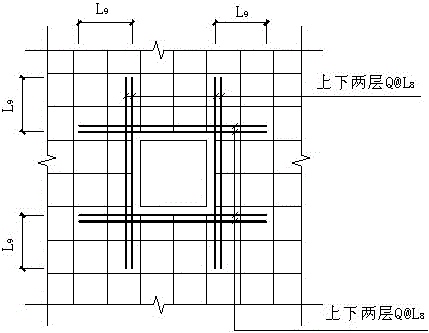

[0034] Realize the present invention: a kind of high-rise building friction pile foundation reinforcement rectification technology, the concrete steps that take are as follows:

[0035] 1. Analysis of settlement and inclination of high-rise buildings:

[0036] (1) Settlement and tilt displacement monitoring:

[0037] Before strengthening and rectifying high-rise buildings, set a displacement observation point at the four corners of the building, large corners, and each column (wall), and mark the horizontal line; set at the main control side column (wall) and corner column (wall) Tilt observation point (according to the shape of the building, combined with the "Building Deformation Measurement Specification" JGJ8, set the specific position of the displacement and tilt observation point). Total station, high-precision level and steel ruler are used to comprehensively monitor the settlement and inclination of the building; the settlement and inclination data are analyzed to fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com