Fast preparation method of nanometer cerium dioxide dispersion liquid

A nano-cerium dioxide and dispersion liquid technology, which is applied in the field of nano-materials, can solve the problems of long production cycle, explosion of high-pressure liquid phase reaction equipment, complex process, etc., and achieve the effects of easy temperature control, improved stability, and low sedimentation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

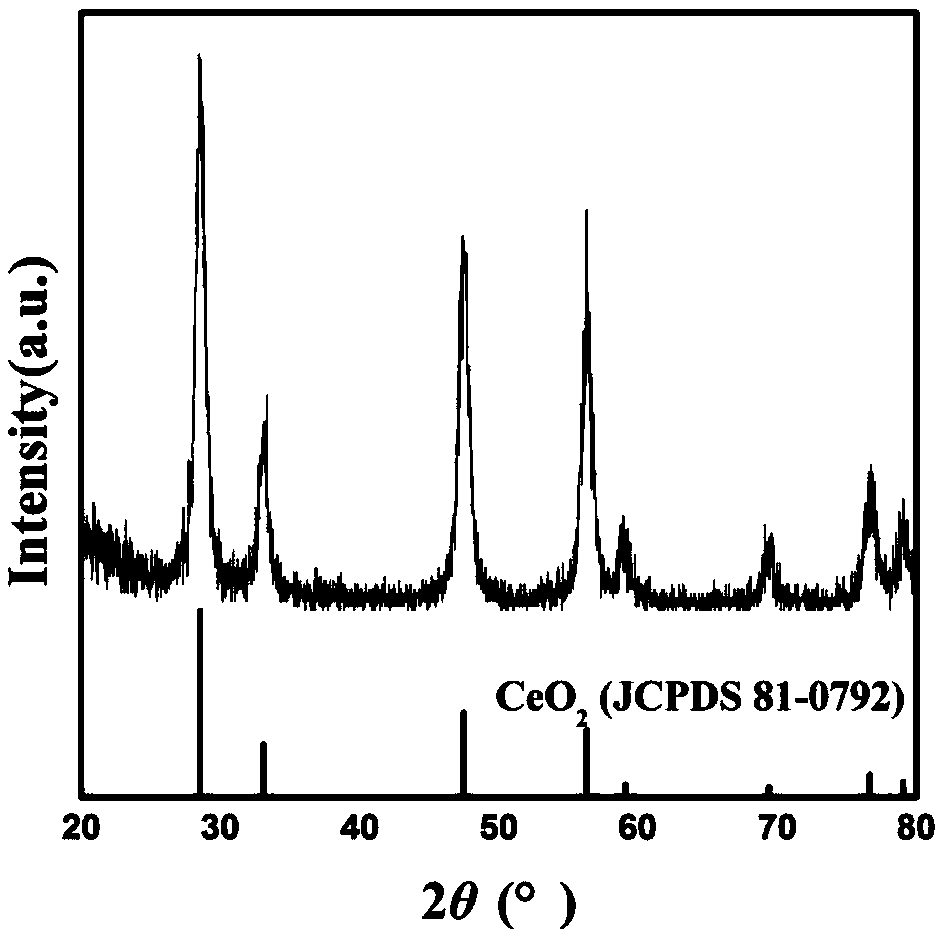

Embodiment 1

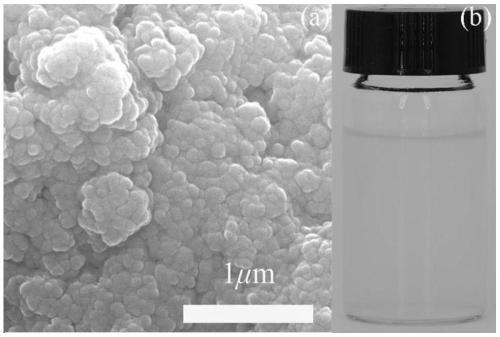

[0033] 0.8 mmol cerium chloride heptahydrate (CeCl 3 ·7H 2 O) dissolved in 40ml deionized water, configured as cerium ion (Ce 3+ ) is an aqueous solution with a concentration of 0.02mol / L; the temperature is raised to 70°C at a rate of 5°C / min, and continuously stirred at a rate of 800rpm; the temperature of the aqueous solution is kept at 70°C, and 2.4mmol of NaOH is added thereto, and the stirring rate is maintained at 800rpm Continue the reaction for 0.5h until the precipitation is complete, reduce the stirring rate to 300rpm and continue the reaction for 3h; centrifuge the nanocrystals in the aqueous solution at a speed of 3000rpm, and use deionized water to ultrasonically clean 4 times to obtain ceria with a particle size of about 100nm Nanoparticles: Weigh 0.8g of the above-prepared ceria nanoparticles and redissolve them in 40ml of deionized water, and add 0.04g of PVA and 0.04g of SDBS to it, and ultrasonically treat them for 30min until they are uniformly dispersed t...

Embodiment 2

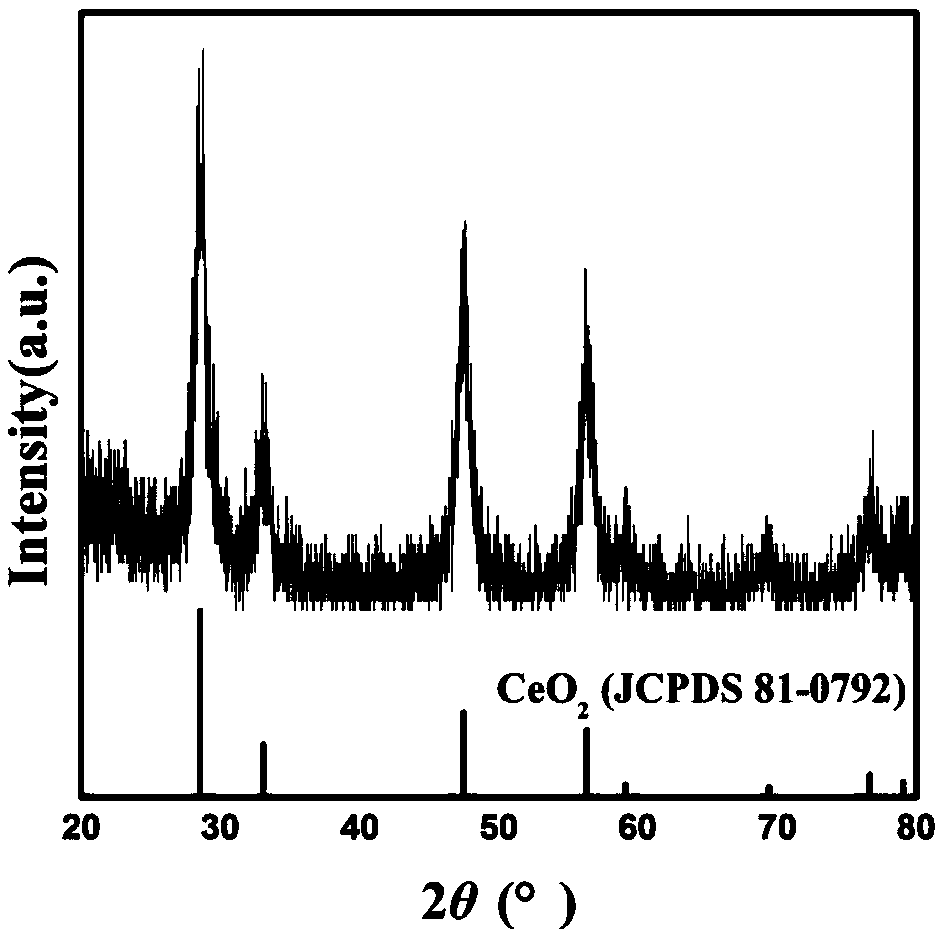

[0037] 0.8 mmol cerium chloride heptahydrate (CeCl 3 ·7H 2 O) and 0.05g SDBS are dissolved in 40ml deionized water to configure cerium ion (Ce 3+ ) is an aqueous solution with a concentration of 0.02mol / L; the temperature is raised to 70°C at a rate of 5°C / min, and continuously stirred at a rate of 800rpm; the temperature of the aqueous solution is kept at 70°C, and 2.4mmol of NaOH is added thereto, and the stirring rate is maintained at 800rpm Continue the reaction for 0.5h until the precipitation is complete, reduce the stirring rate to 300rpm and continue the reaction for 3h; centrifuge the nanocrystals in the aqueous solution at a speed of 3000rpm, and use deionized water to ultrasonically clean 4 times to obtain ceria with a particle size of about 800nm Particles: Weigh 0.8 g of the above-prepared ceria particles and redissolve them in 40 ml of deionized water, add 0.04 g of PVA and 0.3 ml of oleic acid to it, and ultrasonically treat for 30 minutes until uniformly dispe...

Embodiment 3

[0041] 0.8 mmol cerium chloride heptahydrate (CeCl 3 ·7H 2 O) dissolved in 40ml deionized water, configured as cerium ion (Ce 3+ ) concentration is an aqueous solution of 0.02mol / L; the temperature is raised to 90°C at a rate of 5°C / min, and continuously stirred at a rate of 800rpm; the temperature of the aqueous solution is maintained at 90°C, 2.4mmol of NaOH is added thereto, and the stirring rate is maintained at 800rpm Continue the reaction for 0.5h until the precipitation is complete, reduce the stirring rate to 300rpm and continue the reaction for 3h; centrifuge the nanocrystals in the aqueous solution at a speed of 3000rpm, and use deionized water to ultrasonically clean 4 times to obtain ceria with a particle size of about 50nm Nanoparticles: Weigh 0.8g of the above-prepared ceria nanoparticles and redissolve them in 40ml of deionized water, and add 0.04g of PVP and 0.3ml of Tween 80 to it, and ultrasonically treat them for 30min until they are evenly dispersed to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com