Outdoor reconsolidated bamboo product and preparation method

A recombined bamboo and outdoor technology, applied in the direction of manufacturing tools, mechanical equipment, wooden veneer joints, etc., to achieve the effects of increasing product added value, strong light aging resistance, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0029] Experimental example 1: Effect of heat treatment on the performance of outdoor reconstituted bamboo

[0030] 1.1 Materials and equipment

[0031] Enzymatic lignin (EHL) [Main performance indicators: hydroxyl content of 1.87mmol (31P NMR), number average molecular weight of 1430g / mol (GPC), clarson lignin content of 84.91%, can be well soluble in N,N- Dimethylformamide (DMF) and tetrahydrofuran (THF)], Hong Kong Laihe Biomass Co., Ltd., China.

[0032] Tablet Press (PC-5), Tianjin Jingtuo Instrument Technology Co., Ltd., China; Portable Colorimeter (CR-10), Konica Minolta Co., Ltd. (KONICAMINOLTA), Japan; UV-Vis Spectrophotometer (UV-2401PC), Shimadzu Corporation, Japan; Fourier Transform Infrared Spectrometer (Nicolet iS10), Thermo (Thermo) Technology Co., Ltd., the United States; Thermogravimetric Analyzer (DTG-60), Shimadzu Corporation, Japan; Mass spectrometer (solanX 70FT-MS), Bruker Dalton Company, USA.

[0033] 1.2 Method

[0034] Lignin circle preparation and...

experiment example 2

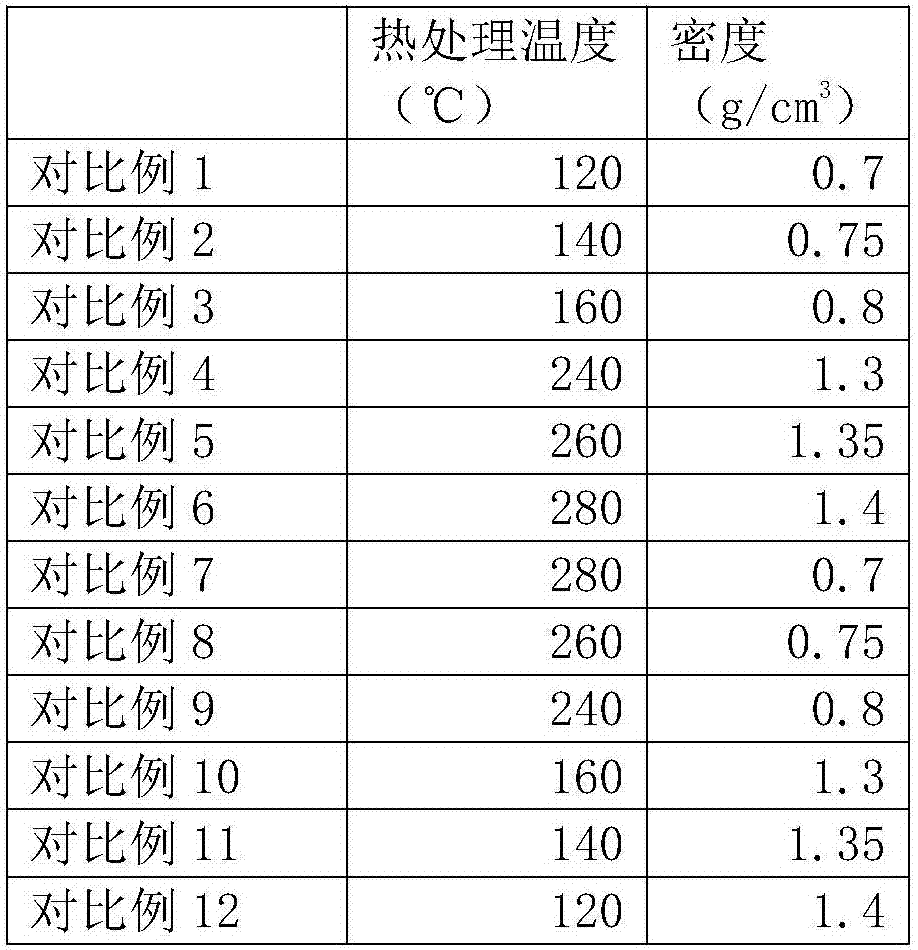

[0047] Experimental example 2: Research on the influence of outdoor reconstituted bamboo manufacturing and density on performance

[0048] 2.1 Materials and equipment

[0049] Finely decomposed bamboo bundles were purchased from Anhui Hongyu Bamboo Technology Co., Ltd., China; phenolic resin glue [main performance indicators: viscosity 36m Pa·S (25°C), solid content 46.2%, pH value 10-11], Beijing Taier Chemical Co., Ltd., China.

[0050] Heat press machine (QD-100), Shanghai Wood-based Panel Machinery Factory Co., Ltd., China; Accelerated UV aging test chamber, Hangzhou Jiuhuan Fuda Industrial Co., Ltd., China; Universal mechanical testing machine (50KN), Instron Corporation, USA; Scanning Electron Microscope (S-3400N), Hitachi Group, Japan; Portable Colorimeter (CR-10), Konica Minolta Co., Ltd., Japan; Gloss Meter (60°), Boncy Instruments Technology (Shanghai) Co., Ltd., China; UV-Vis spectrophotometer (UV-2401PC), Shimadzu Corporation, Japan; precision roughness meter (JB...

experiment example 3

[0064] Experimental example 3: Comprehensive treatment plan for outdoor reconstituted bamboo

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com