High-thermal-conductivity elastomer applied to new energy charging pile cable and preparation method

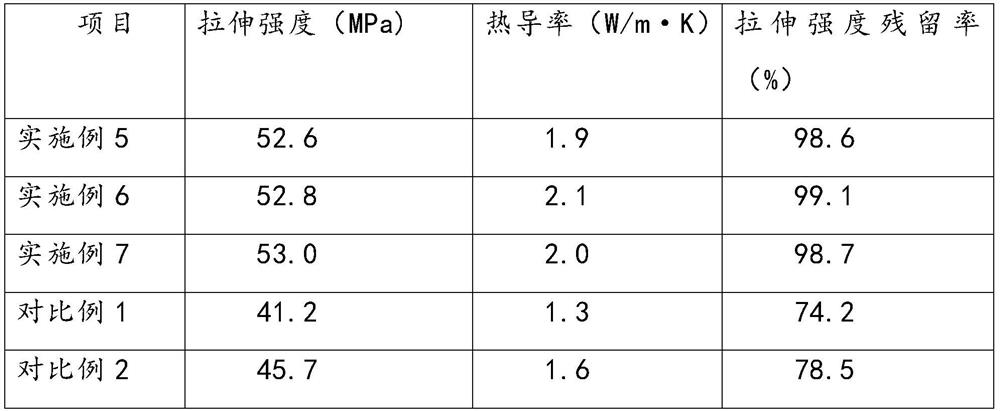

A charging pile, high thermal conductivity technology, applied in electric vehicle charging technology, electric vehicles, vehicle energy storage, etc., can solve the problems of cable service life reduction, poor light and thermal stability, poor aging resistance, etc., to reduce the transmission of electric energy, Strong light aging resistance and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The present embodiment provides a modified carbon nanotube, which is made by the following steps:

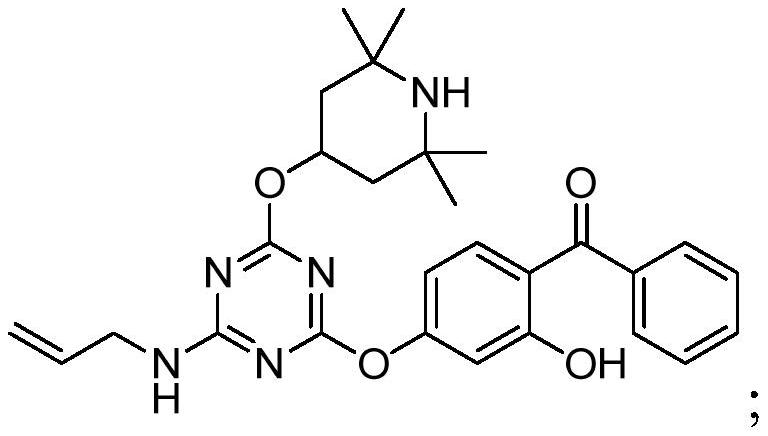

[0038] Step A1: Mix 0.01mol tetramethylpiperidinol, 0.8g sodium hydroxide, 0.04g methyltrioctylammonium chloride and 30mL anhydrous toluene, add cyanuric chloride solution dropwise in a water bath at 40°C, and stir The reaction was carried out for 4 h, filtered, and the filtrate was distilled under reduced pressure to remove toluene to obtain intermediate 1. The cyanuric chloride solution in toluene was prepared by mixing cyanuric chloride and toluene according to the dosage ratio of 0.01 mol: 20 mL;

[0039] Step A2: Mix 3.36g of Intermediate 1, 50mL of anhydrous toluene, and 1.25g of potassium carbonate, under nitrogen protection, stir in a water bath at 50°C, and then add allylamine toluene solution dropwise. After the dropwise addition, stir and react for 3h, filter , the filtrate is distilled under reduced pressure to remove toluene to obtain intermediate 2, and the ...

Embodiment 2

[0045] The present embodiment provides a modified carbon nanotube, which is made by the following steps:

[0046] Step A1: Mix 0.01 mol of tetramethylpiperidinol, 1.0 g of sodium hydroxide, 0.04 g of methyltrioctyl ammonium chloride and 40 mL of anhydrous toluene, add cyanuric chloride solution dropwise in a water bath at 40°C, and stir The reaction was carried out for 5 h, filtered, and the filtrate was distilled under reduced pressure to remove toluene to obtain intermediate 1. The cyanuric chloride solution in toluene was prepared by mixing cyanuric chloride and toluene according to the dosage ratio of 0.01 mol: 20 mL;

[0047] Step A2: Mix 3.36 g of Intermediate 1, 80 mL of anhydrous toluene, and 1.38 g of potassium carbonate, and under nitrogen protection, stir in a water bath at 50 °C, and then add allylamine toluene solution dropwise. After the dropwise addition, stir and react for 4 hours, and filter , the filtrate is distilled under reduced pressure to remove toluene ...

Embodiment 3

[0053] The present embodiment provides a kind of modified nano titanium dioxide, which is made by the following steps:

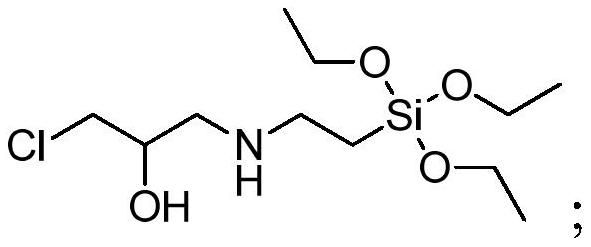

[0054] Step B1, put 35mL of anhydrous toluene in a three-necked flask, add 0.1mol KH-550, ice bath condition, dropwise add 0.105mol epichlorohydrin, after the dropwise addition, stir the reaction for 1h, remove the ice bath after the reaction is completed , continue to stir for 2h, spin the reaction product, when no more droplets drip from the condenser, place under vacuum and stir for 2h to obtain chlorosilane;

[0055] Step B2: Mix 0.1 g of chlorosilane, 10 mL of deionized water and 10 mL of absolute ethanol, add 2 g of nano-titanium dioxide, and stir for 4 hours. After the reaction, centrifuge at a speed of 1500 r / min, and wash the precipitate with deionized water for 3 times. , and vacuum dried to constant weight at 80°C to obtain modified nano-titanium dioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com