High dyeability EVA color master batch special for shoes and preparation method thereof

A coloring and shoe material technology, applied in the application, footwear, clothing and other directions, can solve the problems of strong resistance to thermal oxidation aging, large color difference, uneven color and luster, achieve good coloring and molding processability, improve compatibility , the effect of good surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

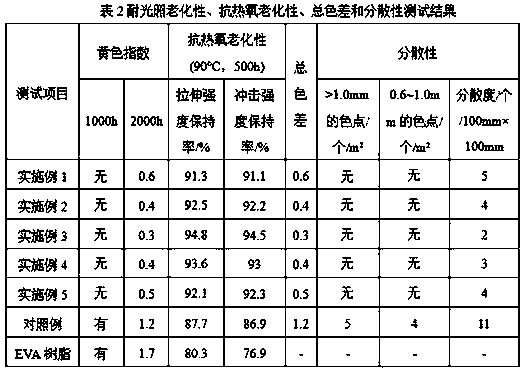

Examples

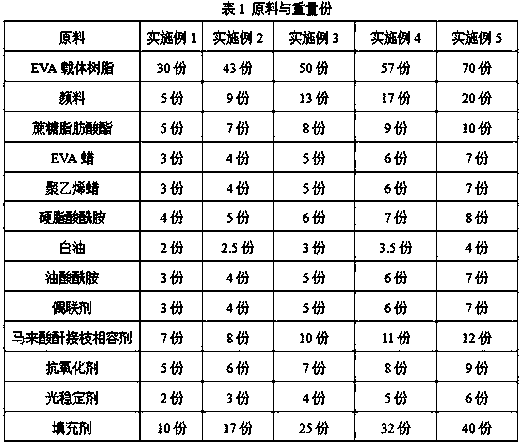

Embodiment 1

[0025] This embodiment provides a special EVA masterbatch for shoe materials with strong colorability, including the following raw materials in parts by weight: 30 parts of EVA carrier resin, 5 parts of pigment, 5 parts of sucrose fatty acid ester, 3 parts of EVA wax, 3 parts of polyethylene wax 4 parts, stearic acid amide 4 parts, white oil 2 parts, oleic acid amide 3 parts, coupling agent 3 parts, maleic anhydride graft compatibilizer 7 parts, antioxidant 5 parts, light stabilizer 2 parts, filler 10 parts; wherein, the VA content of the EVA carrier resin is 15%; the pigment is a mixture of inorganic pigments and organic pigments with a weight ratio of 5:2; the coupling agent is a silane with a weight ratio of 6:3 A mixture of a coupling agent and a titanate coupling agent; the filler is a mixture of heavy calcium carbonate, kaolin, silicon dioxide and diatomaceous earth in a weight ratio of 6:3:8:2; the antioxidant is A mixture of antioxidant 1010, antioxidant 168 and auxili...

Embodiment 2

[0034] This embodiment provides a special EVA masterbatch for shoe materials with strong colorability, including the following raw materials in parts by weight: 43 parts of EVA carrier resin, 9 parts of pigment, 7 parts of sucrose fatty acid ester, 4 parts of EVA wax, 4 parts of polyethylene wax 5 parts of stearic acid amide, 2.5 parts of white oil, 4 parts of oleic acid amide, 4 parts of coupling agent, 8 parts of maleic anhydride grafted compatibilizer, 6 parts of antioxidant, 3 parts of light stabilizer, filler 17 parts; wherein, the VA content of the EVA carrier resin is 20%; the pigment is a mixture of inorganic pigments and organic pigments with a weight ratio of 5.5:2.7; the coupling agent is a silane with a weight ratio of 7:4 A mixture of a coupling agent and a titanate coupling agent; the filler is a mixture of heavy calcium carbonate, kaolin, silicon dioxide and diatomaceous earth in a weight ratio of 7:4:8.7:3; the antioxidant is A mixture of antioxidant 1010, anti...

Embodiment 3

[0043] This embodiment provides a special EVA masterbatch for shoe materials with strong colorability, including the following raw materials in parts by weight: 50 parts of EVA carrier resin, 13 parts of pigment, 8 parts of sucrose fatty acid ester, 5 parts of EVA wax, and 5 parts of polyethylene wax 6 parts of stearic acid amide, 3 parts of white oil, 5 parts of oleic acid amide, 5 parts of coupling agent, 10 parts of maleic anhydride grafted compatibilizer, 7 parts of antioxidant, 4 parts of light stabilizer, filler 25 parts; wherein, the VA content of the EVA carrier resin is 21%; the pigment is a mixture of inorganic pigments and organic pigments with a weight ratio of 6:3.5; the coupling agent is a silane with a weight ratio of 8:5 A mixture of a coupling agent and a titanate coupling agent; the filler is a mixture of heavy calcium carbonate, kaolin, silicon dioxide and diatomaceous earth in a weight ratio of 8:5:9:4; the antioxidant is A mixture of antioxidant 1010, anti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com