Softening treatment method for bamboo

A softening treatment, bamboo technology, applied in the direction of wood treatment, pressurized wood treatment, wood treatment details, etc., can solve the problems of long treatment time, difficult to soften the shape again, and little improvement effect, so as to improve the quality and life of use , Promote the value of use, and achieve the effect of recovery and improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of softening treatment method of bamboo, comprises the steps:

[0028] (1) Bamboo pretreatment:

[0029] After removing the tips and leaves of the bamboo, the bamboo is cut and segmented according to the processing requirements, and finally rinsed with clean water for later use;

[0030] (2) High temperature and high pressure treatment:

[0031] Put the bamboo treated in step (1) into an airtight tank, preheat the airtight tank to 80°C at a heating rate of 6°C / min, and then inject high-temperature water vapor into it, and control the temperature of the water vapor to 104~ 105°C, at the same time raise the pressure in the airtight tank to 1.5MPa, heat-preserve and pressure-hold the bamboo for 40 minutes, then quickly cool down and release the pressure to normal temperature and pressure, and finally take out the bamboo for later use;

[0032] (3) Ultrasonic cleaning treatment:

[0033] Put the bamboo treated in step (2) into a nitric acid solution with a mass fr...

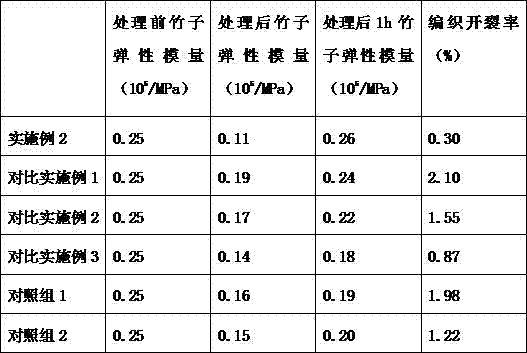

Embodiment 2

[0046] A kind of softening treatment method of bamboo, comprises the steps:

[0047] (1) Bamboo pretreatment:

[0048] After removing the tips and leaves of the bamboo, the bamboo is cut and segmented according to the processing requirements, and finally rinsed with clean water for later use;

[0049] (2) High temperature and high pressure treatment:

[0050] Put the bamboo treated in step (1) into an airtight tank, preheat the airtight tank to 83°C at a heating rate of 7°C / min, and then pass high-temperature water vapor into it, and control the temperature of the water vapor to 105~ 106°C, at the same time raise the pressure in the airtight tank to 1.8MPa, heat-preserve and pressure-hold the bamboo for 45 minutes, then quickly cool down and release the pressure to normal temperature and pressure, and finally take out the bamboo for later use;

[0051] (3) Ultrasonic cleaning treatment:

[0052] Put the bamboo treated in step (2) into a nitric acid solution with a mass frac...

Embodiment 3

[0065] A kind of softening treatment method of bamboo, comprises the steps:

[0066] (1) Bamboo pretreatment:

[0067] After removing the tips and leaves of the bamboo, the bamboo is cut and segmented according to the processing requirements, and finally rinsed with clean water for later use;

[0068] (2) High temperature and high pressure treatment:

[0069] Put the bamboo treated in step (1) into an airtight tank, preheat the airtight tank to 85°C at a heating rate of 8°C / min, and then inject high-temperature water vapor into it, controlling the temperature of the water vapor to be 107~ 108°C, at the same time raise the pressure in the airtight tank to 2MPa, heat-preserve and pressure-hold the bamboo for 50 minutes, then quickly cool down and release the pressure to normal temperature and pressure, and finally take out the bamboo for later use;

[0070] (3) Ultrasonic cleaning treatment:

[0071] Put the bamboo treated in step (2) into a nitric acid solution with a mass f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com