Wood-based high strength elastic composite gel and preparation method thereof

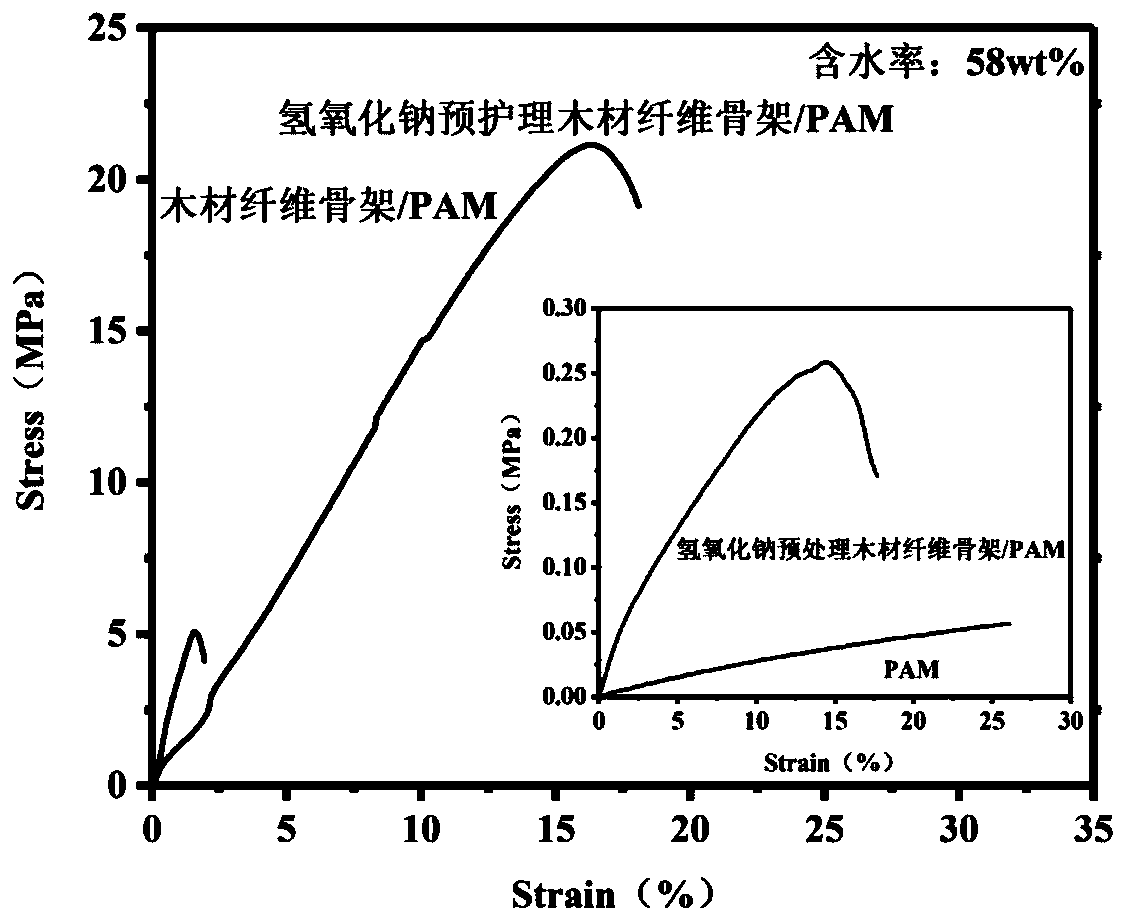

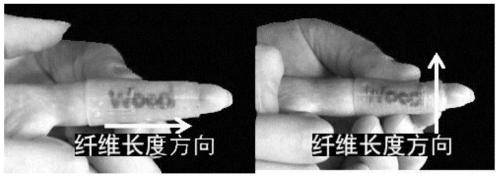

A composite gel and high-strength technology, applied in the manufacture of tools, wood treatment, wood heating, etc., can solve the problems of high moisture content, poor mechanical properties, limited application range, etc., to improve interface bonding and tensile strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The following are the specific steps of the wood-based high-strength gel preparation method of the present invention:

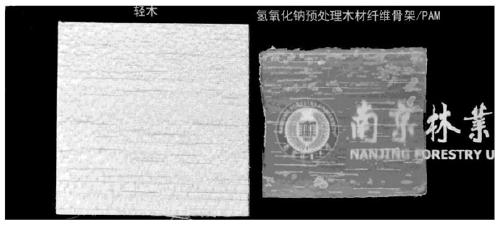

[0029] 1) Extract wood fiber skeleton: put 3 pieces of balsa wood chips (density: 0.16-0.2g / cm3) in 200-400ml 2wt%-3wt% sodium chlorite solution with longitudinal section of 30mm×30mm×1mm, and use acetic acid to adjust the pH Heating at 4-5, 90-100°C for 2-4 hours for delignification of balsa wood. Then rinse with deionized water, fully rinse the obtained wood fiber skeleton to neutrality, and store in ethanol.

[0030] Afterwards, the specific method of treating the wood fiber skeleton with sodium hydroxide solution is: soak the wood fiber skeleton in 15-18 wt% sodium hydroxide solution for 1-3 hours at 25-40°C, and the resulting sodium hydroxide treatment The final wood fiber skeleton was washed with water to neutrality and stored in ethanol.

[0031] 2) Prepare acrylamide solution: put the weighing paper on the weighing balance, clear to zero, wei...

Embodiment 1

[0044] 1) Put three pieces of balsa wood chips (density: 0.16-0.2g / cm3) with longitudinal section of 30mm×30mm×1mm in 200ml, 2 wt% sodium chlorite solution, adjust the pH to 4 with acetic acid, and heat at 90°C for 4 Hours, the balsa wood is delignified. Then rinse with deionized water, fully rinse the obtained wood fiber skeleton to neutrality, and store in ethanol.

[0045] The specific method for treating the wood fiber skeleton with sodium hydroxide solution is: soak the wood fiber skeleton in 18wt% sodium hydroxide solution for 2 hours at 25°C, and rinse the wood fiber skeleton with water to neutral after the sodium hydroxide treatment. , stored in ethanol.

[0046] 2) Put the weighing paper on the weighing balance, reset to zero, weigh 2.766g of acrylamide monomer, pour it into a beaker, then measure 4g of water with a measuring cylinder, pour it into the beaker, and stir. Next, 0.025 g of the cross-linking agent N,N-methylenebisacrylamide was weighed and added into th...

Embodiment 2

[0050] 1) Put three pieces of 30mm×30mm×2mm balsa wood chips in 400ml, 2 wt% sodium chlorite solution, adjust the pH to 5 with acetic acid, and heat at 100°C for 4 hours to delignify the balsa wood. Then rinse with deionized water, fully rinse the obtained wood fiber skeleton to neutrality, and store in ethanol.

[0051] The specific method of treating the wood fiber skeleton with sodium hydroxide solution is: soak the wood fiber skeleton in a sodium hydroxide solution with a concentration of 18wt% at 25°C for 3 hours, and rinse the wood fiber skeleton with water to Neutral, stored in ethanol

[0052] 2) Put the weighing paper on the weighing balance, reset to zero, weigh 2.849g of acrylamide monomer, pour it into a beaker, then measure 4g of water with a measuring cylinder, pour it into the beaker, and stir. Next, 0.033 g of the cross-linking agent N,N-methylenebisacrylamide was weighed and added into the beaker. Then weigh 0.016g of initiator potassium peroxodisulfate, mea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com