Preparing method for outdoor oil heat treatment recombined bamboo wood

A technology for reorganizing bamboo and outdoor materials, applied in wood treatment, wood treatment details, wood heating, etc., can solve the problems of easy deformation, mildew, low viscosity of vegetable oil, limited improvement of mechanical properties, etc., and achieve high utilization rate of raw materials. , The texture is natural and beautiful, and the dimensional stability is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] The preparation method and performance test of the recombined bamboo are as follows.

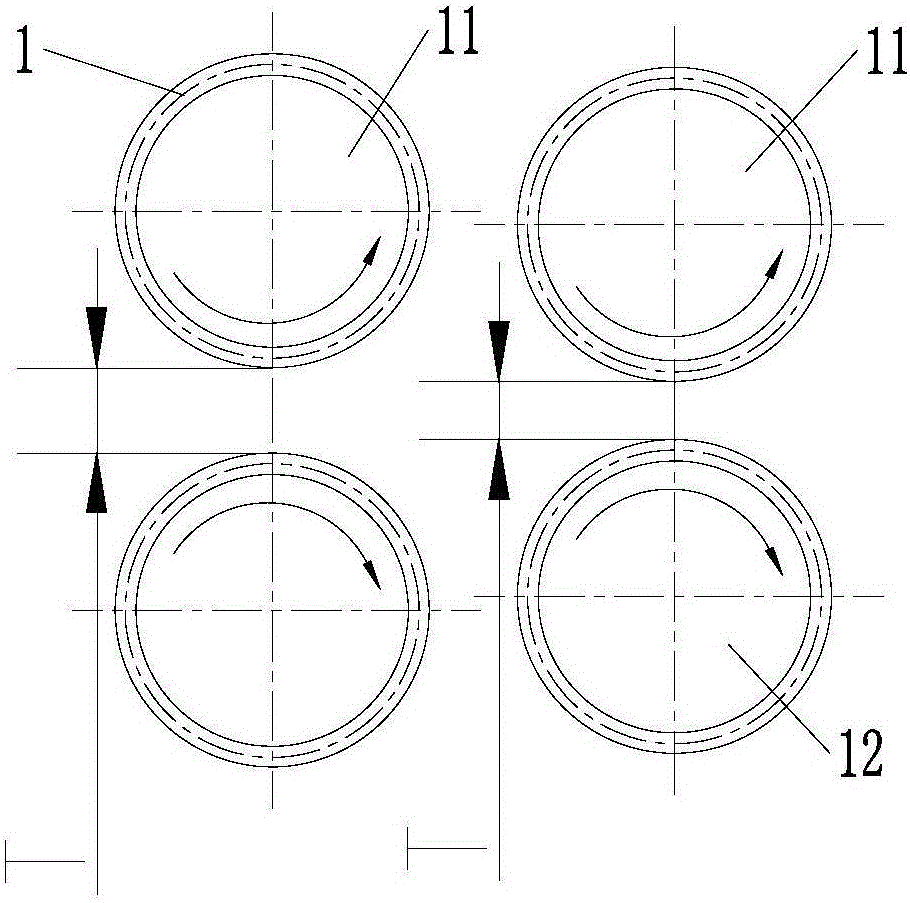

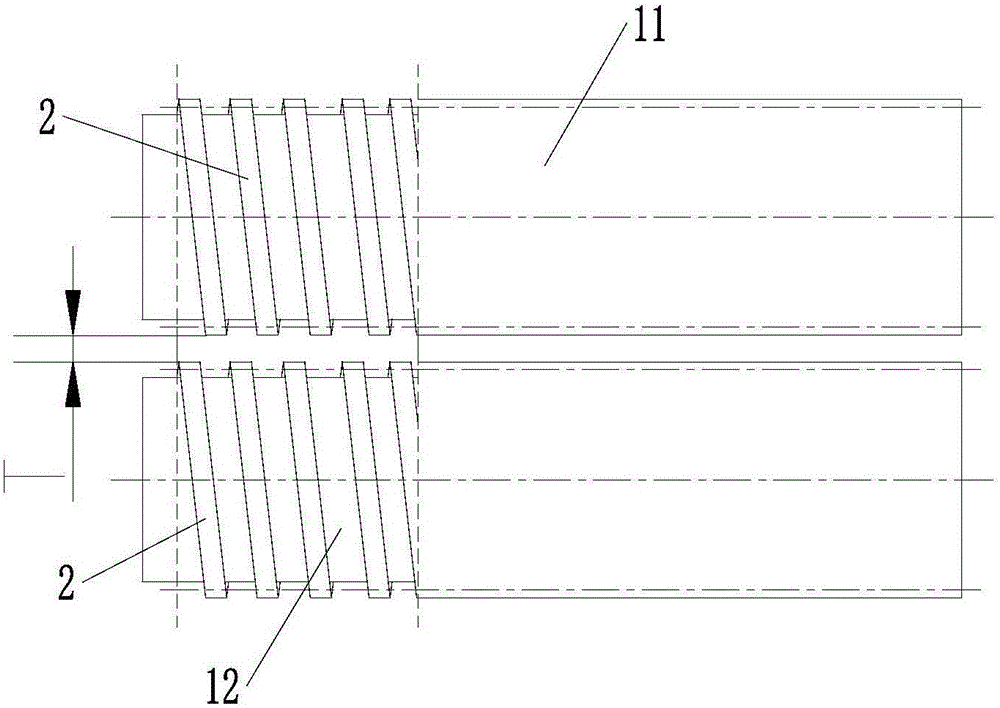

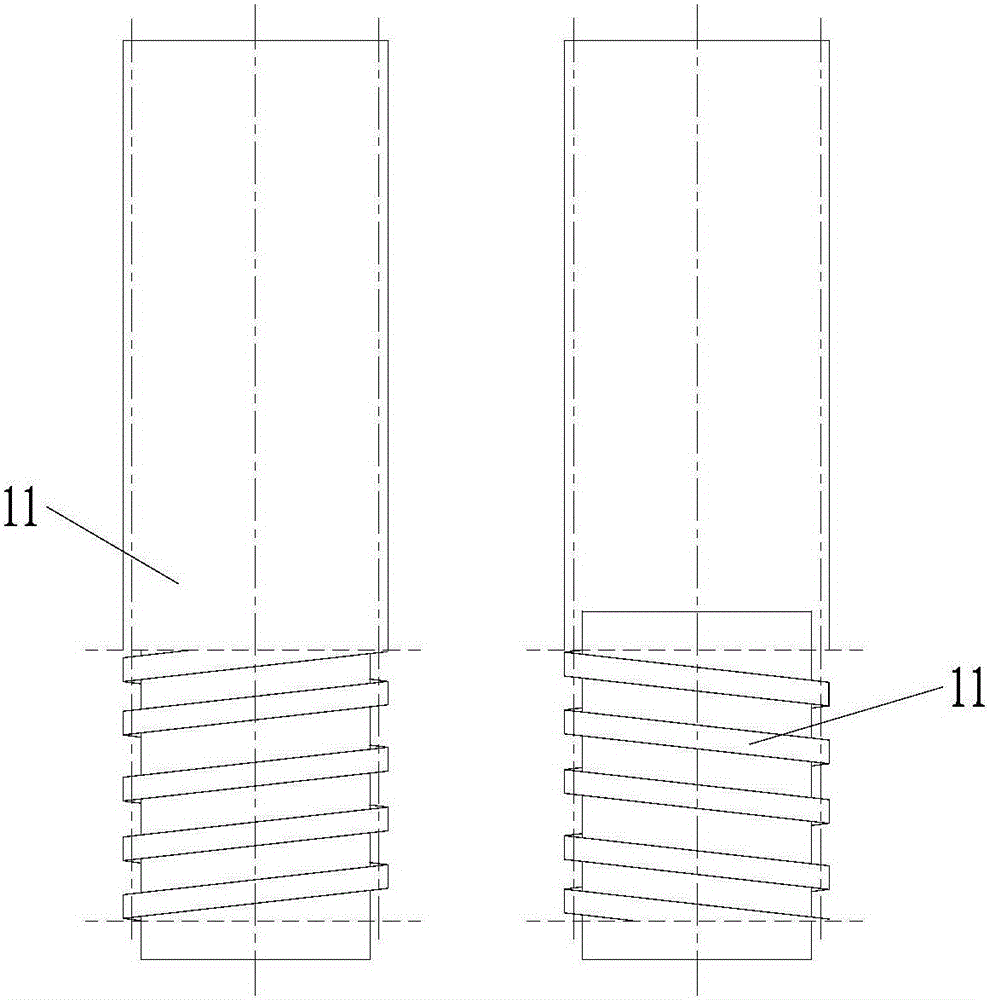

[0019] a, immerse the bamboo (sheet) with a thickness of 8mm under the liquid level of a heat treatment tank equipped with methyl silicone oil, heat the heat treatment tank, so that the methyl silicone oil reaches different temperatures (see Table 1, 2 for details), and keep warm for 2h; b. After 10-15 minutes, release the methyl silicone oil in the heat treatment tank, and take out the sheet; c. Rolling and opening: use rolling equipment. see Figure 1-3 , The rolling equipment includes two pairs of rolling rollers 1 arranged in sequence from left to right. The two rolling rollers 11 and 12 that form a pair of rolling rollers are arranged up and down, and an adjustable gap T is left therebetween. tooth 2. From left to right, the gap between the upper and lower rolling rollers that make up a pair of rolling rollers decreases; and the screw threads of the helical convex teeth of two...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com