Method for preparing composite powder for 3D printing, product and application

A composite powder and 3D printing technology, which is applied in the field of additive manufacturing, can solve the problem that commercial pre-alloyed powder cannot fully meet the requirements of high-performance component manufacturing, and achieve the effect of inhibiting the growth of grains and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

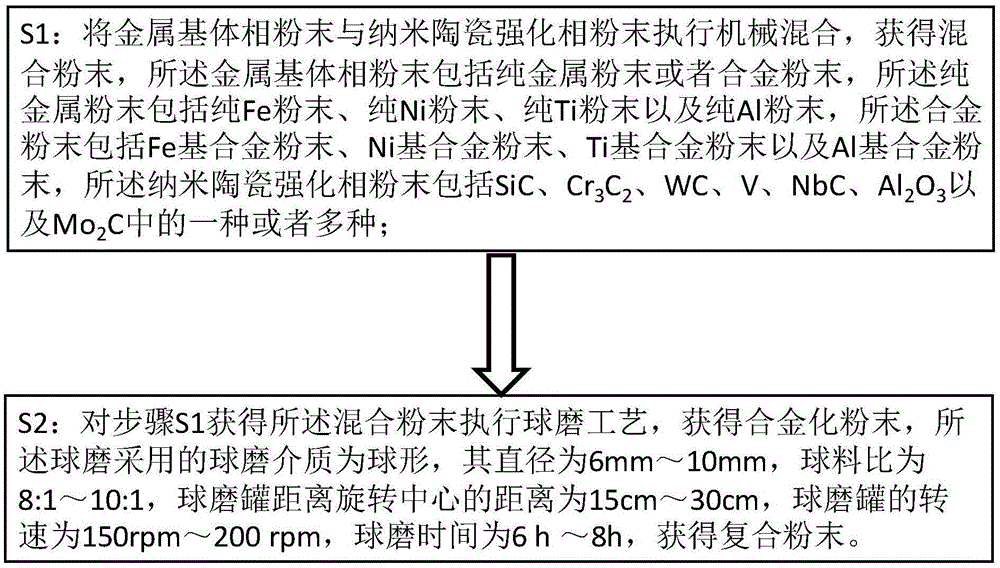

Method used

Image

Examples

Embodiment 1

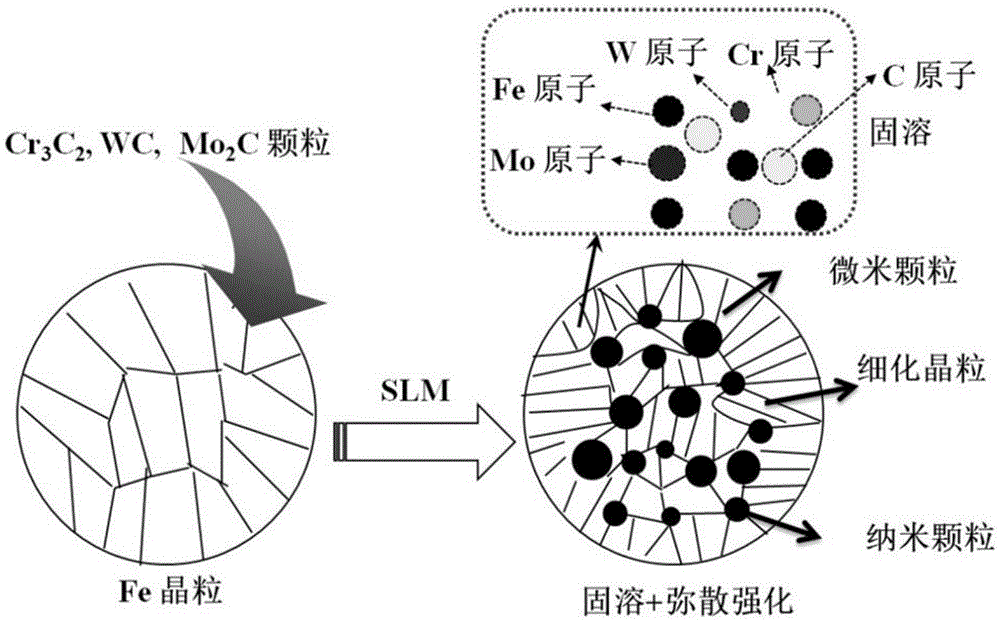

[0036] Example 1 This example is used to prepare W 6 Mo 5 Cr 4 V 2 High carbon and high alloy tool steel.

[0037] W 6 Mo 5 Cr 4 V 2 It is a high-carbon and high-alloy tool steel suitable for high-speed cutting. It is easy to introduce impurity elements such as S and P in the traditional heat treatment process, which weakens the mechanical properties of the alloy to a certain extent. Moreover, the traditional preparation process of cutting tools is complicated and the cycle It's also relatively long. SLM is particularly suitable for the processing of such small cutting tools. The forming process is carried out in a vacuum environment. The composition of the product depends only on the composition of the initial powder, and the purity is very high. Therefore, considering that high-energy laser processing will cause a small amount of volatilization of the elements, and then determine the mass ratio of the initial powder according to the chemical composition of the high-speed tool s...

Embodiment 2

[0046] Embodiment 2 This embodiment is used to prepare a nickel-based superalloy turbine blade.

[0047] Nickel-based superalloys have high strength and good oxidation resistance and gas corrosion resistance in the range of 650℃~1000℃, and are widely used in aerospace hot end parts. For example, Inconel625 is a nickel-based superalloy that has been studied in SLM technology. Due to the extremely fast cooling rate during the SLM forming process, Inconel625 has extremely large micro-residual stress, which is easy to produce micro-cracks at the grain contact boundary, causing the failure of the formed part. In order to suppress the formation of micro-cracks during the SLM forming process, by optimizing the composition of the material and improving the toughness of the material, SLM forming technology can be used to prepare nickel-based superalloy parts with higher strength and toughness. Specifically:

[0048] It includes the following steps:

[0049] S1: First, determine the mass per...

Embodiment 3

[0055] Example 3 This example is used to prepare titanium alloy porcelain teeth.

[0056] Titanium alloys are widely used in aerospace, medical, chemical and other fields because of their high strength, good corrosion resistance, high heat resistance, and good biological compatibility. For example, Ti6Al4V has high strength and good biocompatibility, and can be used to prepare various biological implants such as porcelain teeth and joints. Biological implants have high requirements for wear resistance and strength. Traditional methods The prepared implants tend to have relatively coarse grains and poor performance, and it is difficult to meet the individual requirements of customers. The composite powder is selected and then SLM technology can be used to prepare nano titanium-based alloy porcelain teeth, which have excellent wear resistance and strength, and can also meet the needs of different patients. Specifically:

[0057] It includes the following steps:

[0058] S1: First, d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com