Fuel cell cartridge

A fuel cell and fuel technology, applied in fuel cells, fuel cell additives, secondary batteries, etc., can solve the problems of impact resistance, such as strength reduction, whitening, and deterioration of appearance characteristics, to achieve excellent performance, prevent shrinkage, Effect of preventing fall of impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、5、6

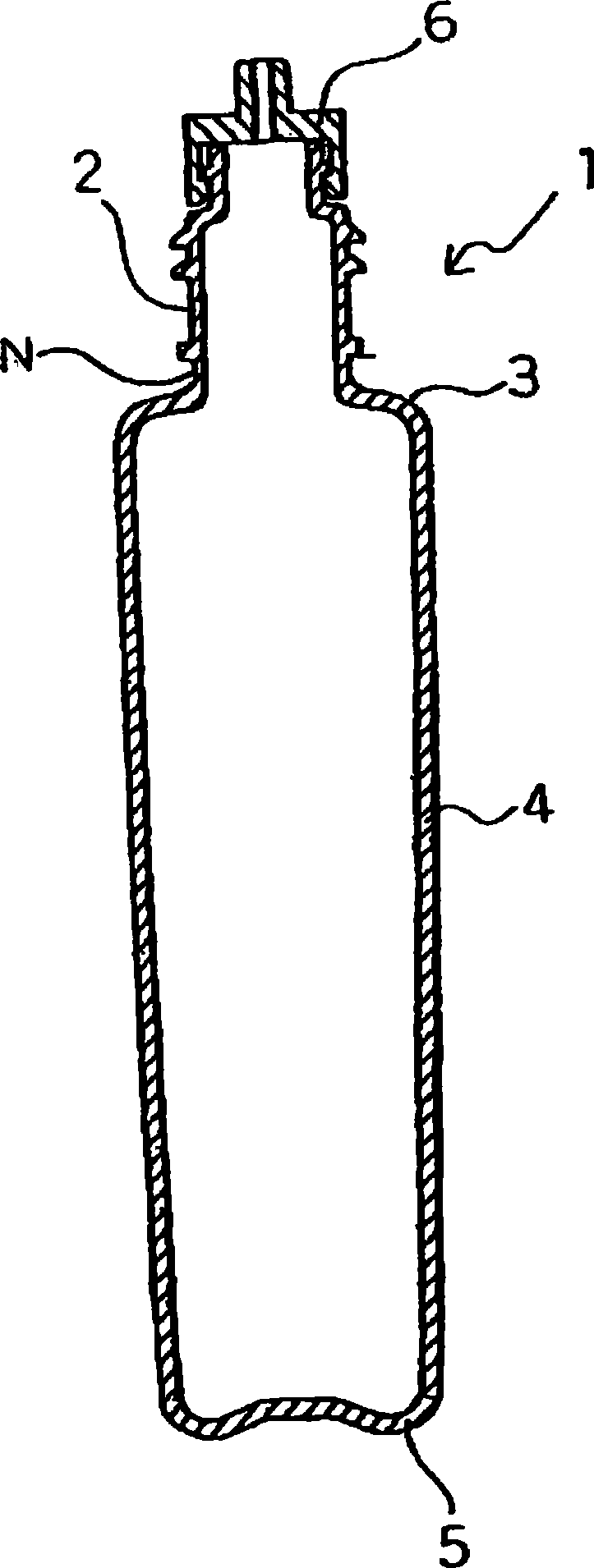

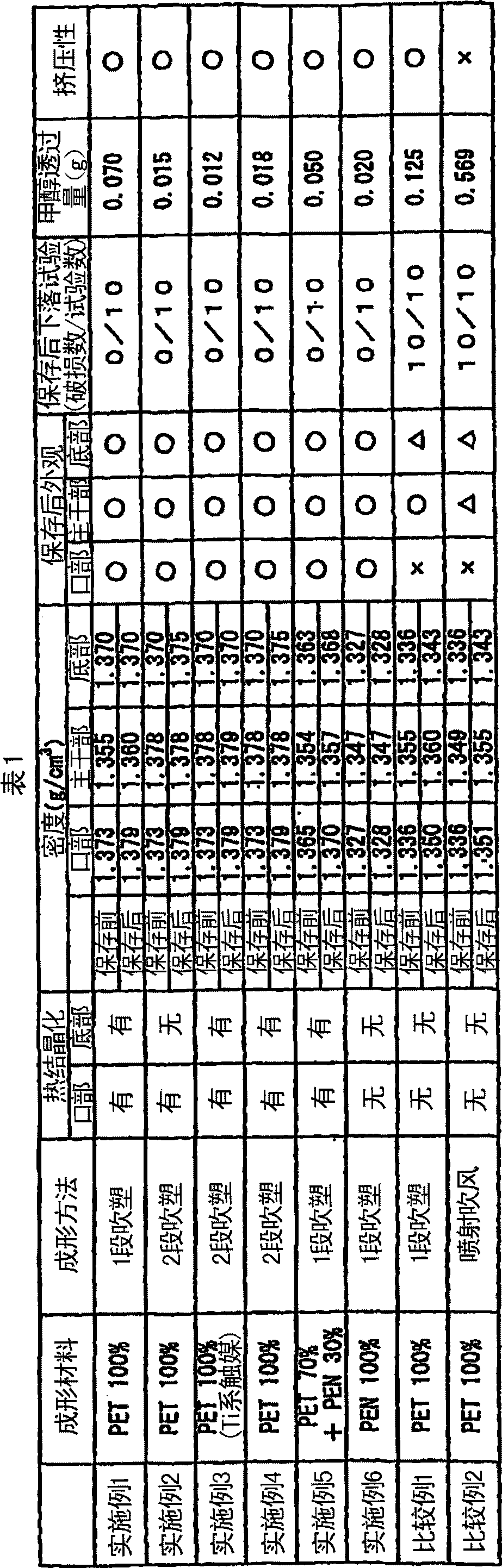

[0076] A preform was formed using the molding materials shown in Table 1, and the mouth portion was thermally crystallized, and the bottom portion was thermally crystallized if necessary. In addition, polyethylene terephthalate (PET) used in Examples 1, 2, 4 to 6 and Comparative Examples 1 and 2 is PET polymerized with a germanium-based catalyst.

[0077] This preform was subjected to one-stage blow molding (stretch ratio: 2.5 times in the longitudinal direction and 2.7 times in the circumferential direction, heat setting conditions: 160°C × 2 seconds), and a diameter (outer diameter of thread teeth) of 18.6 mm and an internal volume of 55 mL were formed. 1. A cylinder with a wall thickness of 0.3mm (the ratio of wall thickness to the wall thickness of the main body of the preform: 0.1) is used.

[0078] The evaluation results are shown in Table 1.

Embodiment 2~3

[0080] A preform was formed using the molding materials shown in Table 1, and the mouth portion was thermally crystallized, and the bottom portion was thermally crystallized if necessary. In addition, PET used in Example 3 is PET polymerized by a titanium-based catalyst.

[0081] This preform is used for secondary blow molding (stretch ratio in the primary blow molding: 2.8 times in the longitudinal direction and 3.3 times in the circumferential direction, heating conditions: 300°C x 10 seconds, processing in the secondary blow molding rate (the difference between the final shape of the container and the volume of the heat-shrinkable bottle) 10%), the formed caliber (outer diameter of the thread) is 18.6mm, the inner capacity is 55mL, and the wall thickness of the main body is 0.3mm (compared to the wall thickness of the main body of the preform). The wall thickness ratio: 0.1) the size of the cylinder.

[0082] The stretch ratio of the formed container based on the size of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com