Manufacturing technology for wood sooting and dyeing

A production process and wood technology, which is applied in the field of wood blackening and dyeing production process, can solve the problems of complicated steps and time-consuming dyeing method, and achieve the effects of direct indication, extended service life and long use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0073] The manufacturing process of the blackened and dyed wood, the process comprises the following steps:

[0074] a. Prepare the sulfate dyeing solution of metal ions, put the wood into the dyeing solution of metal ions and cook for 1.2-1.5h, the cooking temperature is 92-98°C, and clean with clear water for 2-3 times; in this implementation In the example, the metal ion is Fe 2+ , Na + ,Mn2 + ,Cu 2+ One of them, the wood is put into the dyeing solution of metal ions and cooked for 1.3h, the cooking temperature is 96°C, and washed with clean water, the number of times of washing is 2 times;

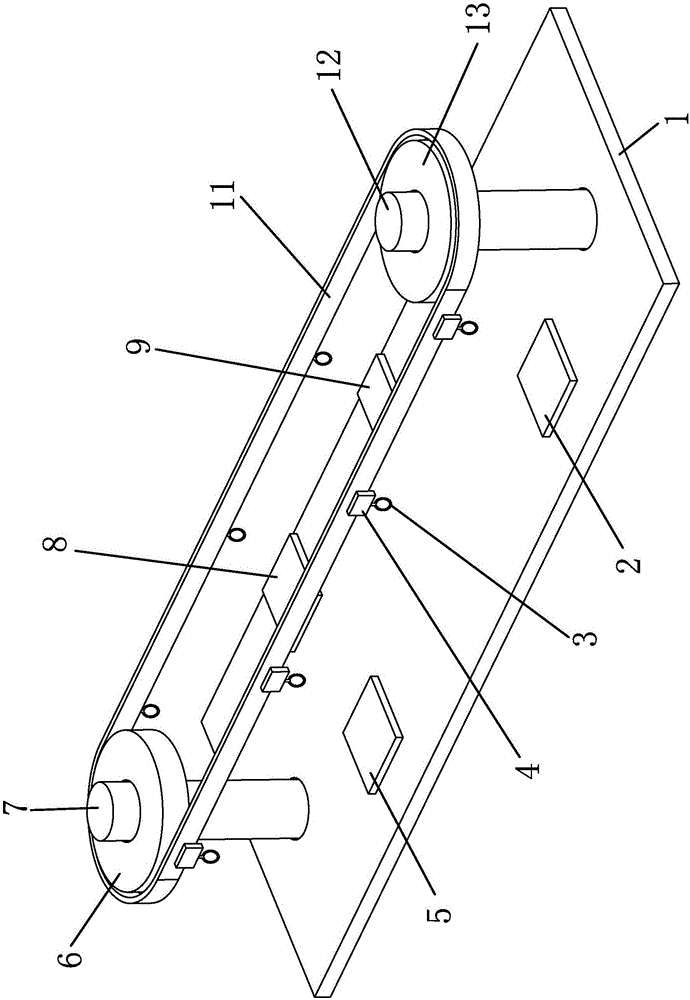

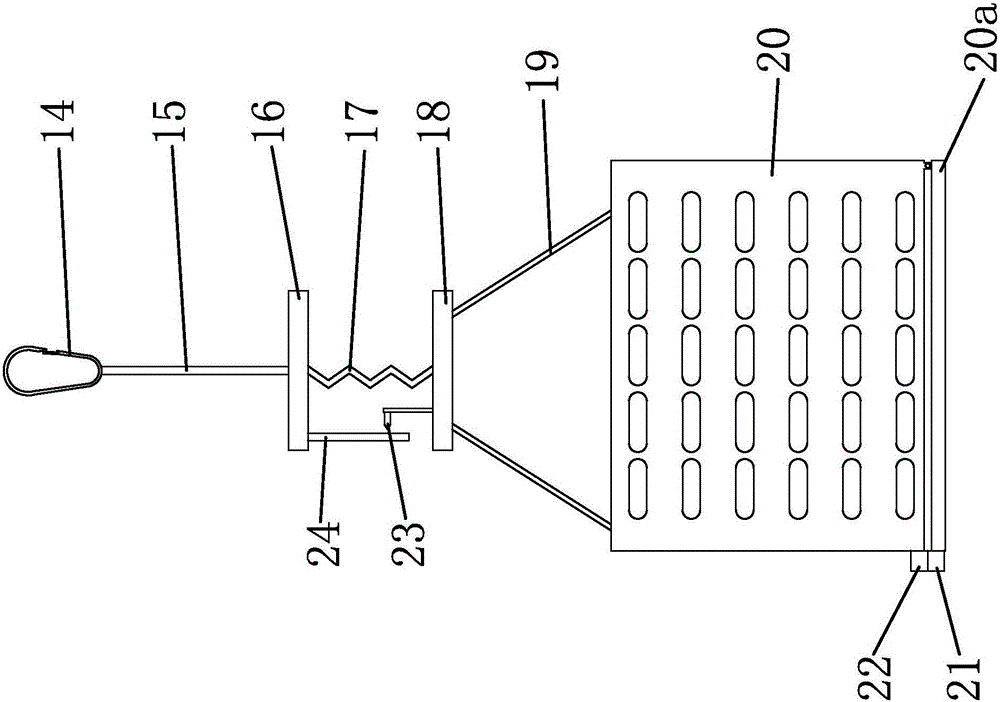

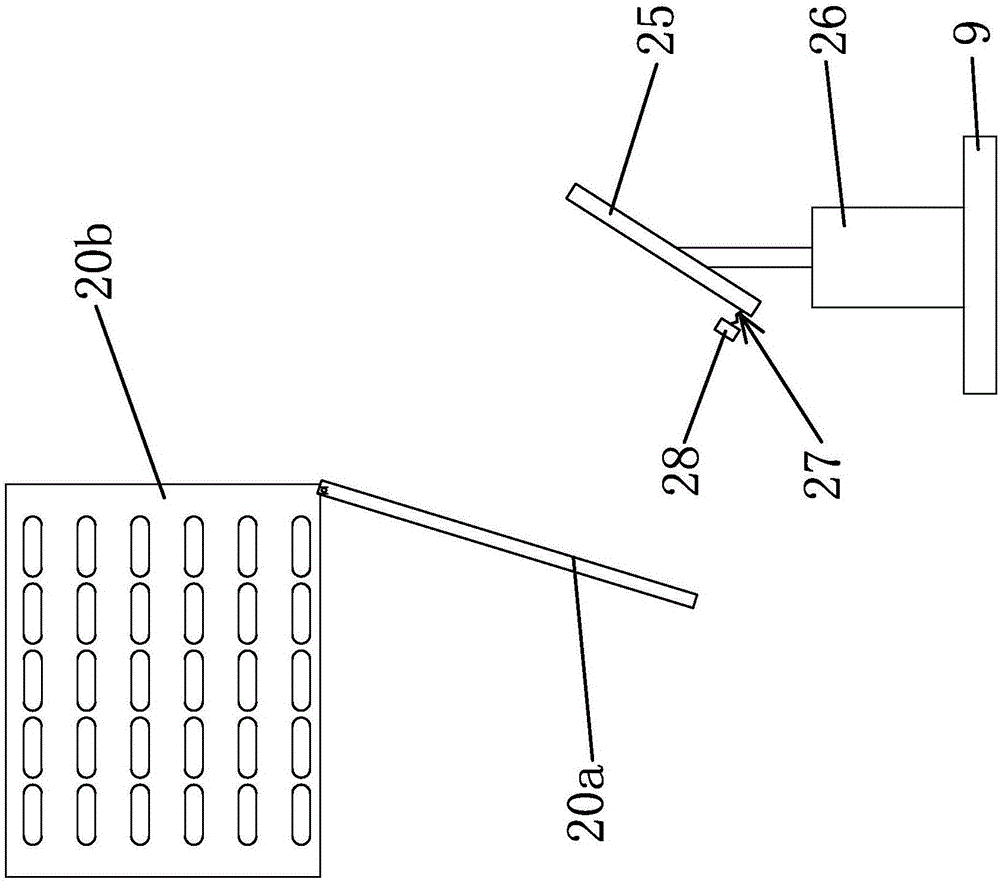

[0075] b. Use the treatment equipment to cold-soak wood with the comfrey plant dye extract at normal temperature and pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com