Low-temperature oil-heat bamboo modifying processing method

A processing method and thermal modification technology, which is applied in wood processing equipment, wood treatment, wood heating, etc., can solve the problems of long technical treatment cycle and the influence of bamboo physical and mechanical properties, so as to improve the anti-corrosion and mildew resistance and the long-lasting protection effect , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

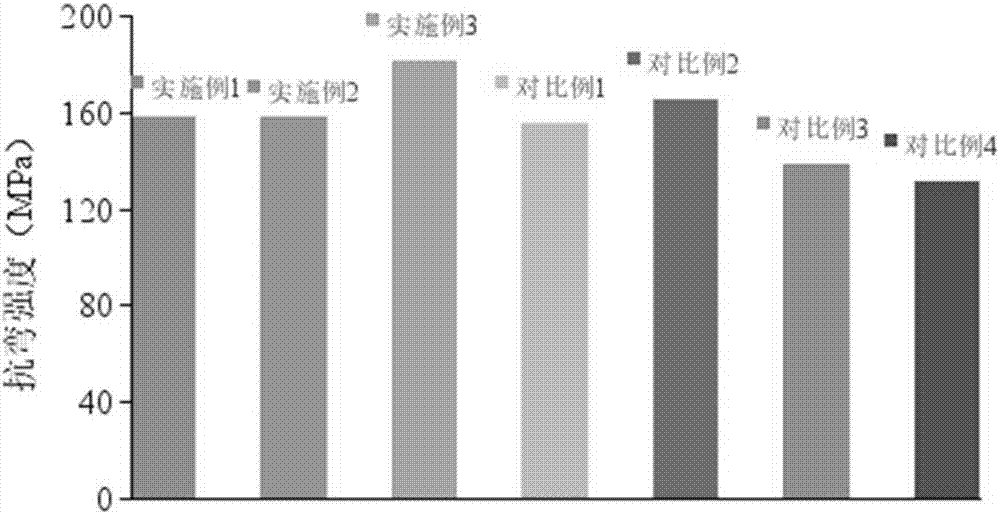

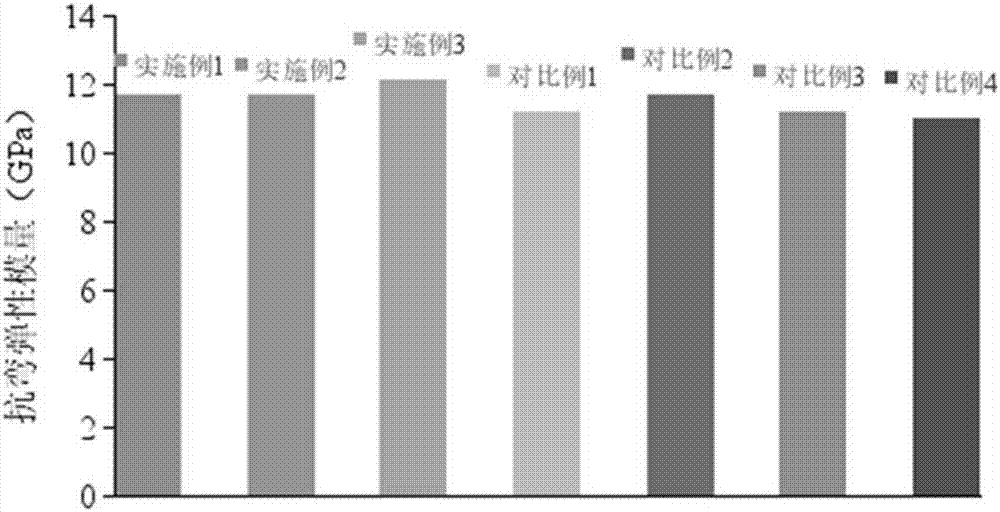

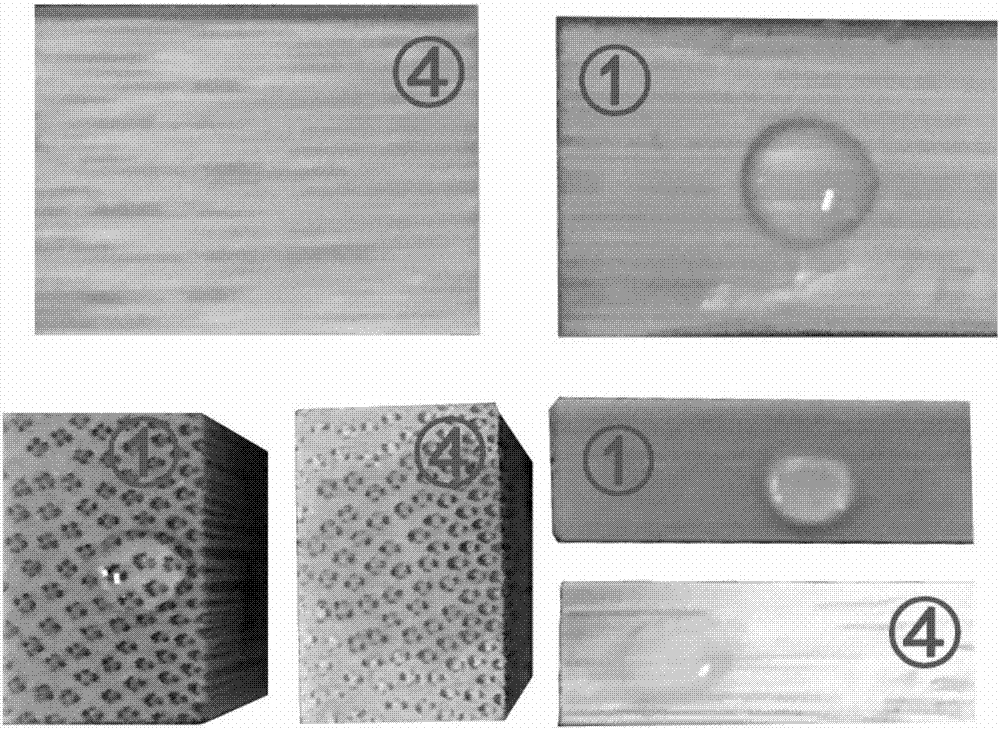

Examples

Embodiment 1

[0025] (1) Bamboo drying: take moso bamboo as an example, first process it into bamboo strips with a thickness of 6mm, and dry the bamboo to a moisture content of 12%;

[0026] (2) Prepare the solution: add maleic anhydride to tung oil at a temperature of 70°C, the mass ratio of tung oil to maleic anhydride is 1:20, start the stirrer, and stir until completely mixed;

[0027] (3) Solution heating: heat the prepared mixed oil solution to 140°C;

[0028] (4) Treatment stage: immerse the bamboo in constant temperature hot oil and heat it for 1 hour;

[0029] (5) Surface treatment: take out the bamboo, wipe off the excess oil solution on the surface, and then cool and dry in the natural environment;

[0030] (6) End-capping treatment: Carbonize the cross-section of the fully dried bamboo.

Embodiment 2

[0032] (1) Bamboo drying: take moso bamboo as an example, first process it into bamboo strips with a thickness of 6mm, and dry the bamboo to a moisture content of 12%;

[0033] (2) Prepare the solution: add maleic anhydride to soybean oil at a temperature of 70°C, the mass ratio of soybean oil to maleic anhydride is 1:10, start the agitator, and stir thoroughly until completely mixed;

[0034] (3) Solution heating: heat the prepared mixed oil solution to 140°C;

[0035] (4) Treatment stage: immerse the bamboo in constant temperature hot oil and heat it for 1 hour;

[0036] (5) Surface treatment: take out the bamboo, wipe off the excess oil solution on the surface, and then cool and dry in the natural environment;

[0037] (6) End-capping treatment: Carbonize the cross-section of the fully dried bamboo.

Embodiment 3

[0039] (1) Bamboo drying: take moso bamboo as an example, first process it into bamboo strips with a thickness of 6mm, and dry the bamboo to a moisture content of 12%;

[0040] (2) Prepare the solution: add maleic anhydride to tung oil at a temperature of 70°C, the mass ratio of tung oil to maleic anhydride is 1:20, start the stirrer, and stir until completely mixed;

[0041] (3) Solution heating: heat the prepared mixed oil solution to 140°C;

[0042] (4) Treatment stage: immerse the bamboo in constant temperature hot oil, and heat it for 0.5h;

[0043] (5) Surface treatment: take out the bamboo, wipe off the excess oil solution on the surface, and then cool and dry in the natural environment;

[0044] (6) End-capping treatment: Carbonize the cross-section of the fully dried bamboo.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com