Medium and high density artificial board of stalk and producing process and use

A production method and technology of wood-based panels, applied in the direction of manufacturing tools, household components, wood processing appliances, etc., can solve the problems of increased cost of veneer and laminate flooring, pollution of harmful substances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

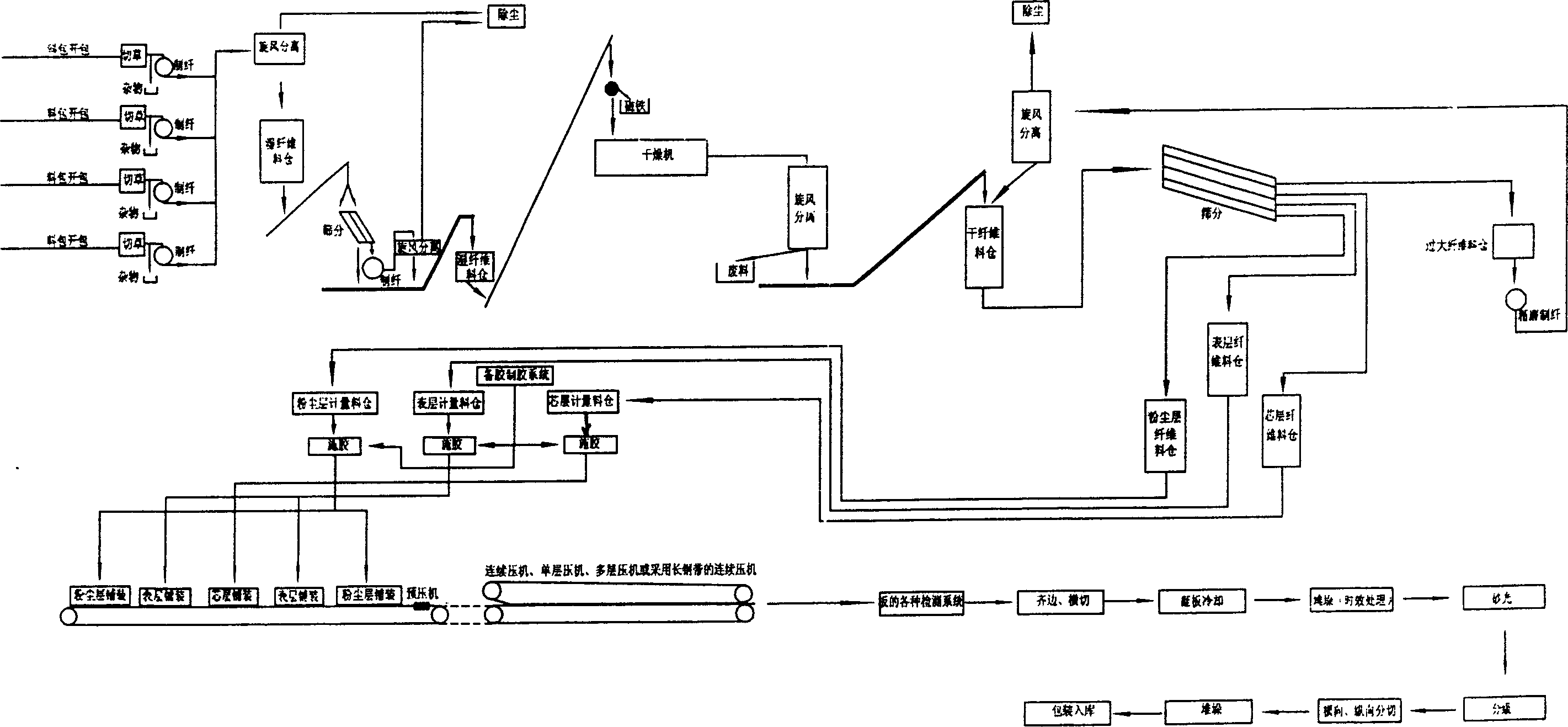

Method used

Image

Examples

Embodiment 2

[0018] Embodiment two, the production process method of this embodiment is exactly the same as the production process method of embodiment one before paving and paving, but the demoulding process adopts the demoulding agent to demould. It needs to spray a release agent on the surface of the paving belt before paving. According to the metering, the surface material and the core material are fully mixed with their respective glues and then transported to the surface and core paving system. The glue used in the surface layer is MDI glue, accounting for 5%; the glue used in the core layer is MD glue, accounting for 7%. Afterwards, the pavement system paves evenly on the pavement belt from bottom to top in the order of the lower surface layer, the core layer, and the upper surface layer. The height and width of pavement are identical with embodiment one. After paving, spray the release agent on the upper surface. Subsequent production process method is identical with embodiment ...

Embodiment 3

[0019] Embodiment three, the production process of this embodiment is exactly the same as the production process of embodiment one before paving and after paving, except that the demoulding process adopts paper demoulding. It needs to lay a layer of paper on the paving belt before paving. Then, the surface layer material and the core layer material are calculated and finally mixed with their respective glues and transported to the surface layer and core layer paving system. The glue used in the surface layer is MDI glue, and the proportion is 3-15%. The additive is industrial urea, with a proportion of 1.5%; the glue used in the core layer is MDI glue, with a proportion of 5.15%. The additive is industrial urea, and the proportion is 1.5%. Afterwards, the pavement system is paved on the pavement belt from bottom to top and evenly in the order of lower surface layer, core layer and upper surface layer. The height and width of pavement are identical with embodiment one. After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com