Polylactic acid wood plastic composite material used for 3D printing musical instrument and preparation method and application thereof

A composite material and polylactic acid wood technology, which is applied in the field of polylactic acid wood-plastic composite materials and preparation, can solve the problems that the device cannot be polished, painted, and is not suitable for printing musical instruments, and achieves a simple and easy preparation scheme, good mechanical strength and Toughness, a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

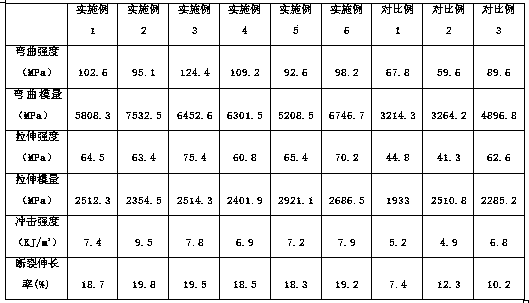

Examples

Embodiment 1

[0037] A polylactic acid wood-plastic composite material for 3D printing musical instruments is blended by the following components by mass percentage: modified rosewood powder 5 wt%, polylactic acid 86 wt%, toughening agent 5 wt%, nano inorganic Filler 3 wt% %, lubricant 1 wt%;

[0038] Wherein, the nano-inorganic filler may preferably be one or both of nano-silicon dioxide, nano-titanium dioxide, and carbon nanotubes. The lubricant may preferably be zinc stearate.

[0039] The toughening agent is preferably SEBS (styrene-butadiene-styrene block copolymer), SBS (thermoplastic polystyrene-polybutadiene-polystyrene block copolymer), TPU (thermoplastic polyurethane elastomer ), TPEE (thermoplastic polyester elastomer) in one or more mixtures.

[0040] The above-mentioned polylactic acid wood-plastic composite material is prepared by the following method:

[0041] S1. Utilize chemical modifier to prepare wood flour into modified wood flour, the specific steps are as follows: ...

Embodiment 2

[0049] The difference between this example and Example 1 is that the polylactic acid wood-plastic composite material used for 3D printing musical instruments is blended from the following components by mass percentage: 20wt% modified acacia wood powder, 62wt% polylactic acid , toughening agent 10 wt%, nano-inorganic filler 5 wt%, lubricant 3 wt%.

[0050] Above-mentioned step S1 is carried out according to the following method:

[0051] S11. Alkali treatment of wood powder, soak 300 mesh acacia wood powder in 5wt% NaOH aqueous solution (the mass ratio of acacia wood powder and NaOH aqueous solution is 1:15) and stir at room temperature for 24 hours, then wash the spruce wood powder with deionized water until Neutral, after filtering with a filter, place the wood powder in an oven at 90 °C for 12 h to obtain alkali-treated wood powder.

[0052] S12. Put the alkali-treated wood powder obtained in step S11 into a reaction vessel containing 5 wt% to 10 wt% maleic anhydride-absolu...

Embodiment 3

[0056] The difference between this example and Example 1 is that the polylactic acid wood-plastic composite material used for 3D printing musical instruments is blended with the following components by mass percentage: modified maple wood powder 15.5wt%, polylactic acid 70wt% %, toughening agent 8wt%, nano inorganic filler 4.5wt%, lubricant 2wt%.

[0057] Above-mentioned step S1 is carried out according to the following method:

[0058] S11. Alkali treatment of wood powder, soak 300 mesh maple wood powder in 5wt% NaOH aqueous solution (the mass ratio of acacia wood powder and NaOH aqueous solution is 1:15) and stir at room temperature for 24 hours, then wash the spruce wood powder with deionized water to Neutral, after filtering with a filter, place the wood powder in an oven at 90 °C for 12 h to obtain alkali-treated wood powder.

[0059] S12. Put the alkali-treated wood powder obtained in step S11 into a reaction vessel equipped with 10 wt% silane coupling agent-absolute et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com