Preparation method of phosphate timber fire retardant and method for processing timber by using fire retardant

A flame retardant and phosphate technology, which is applied in the field of phosphate wood flame retardant preparation, can solve the problems of low cost, low toxicity and high cost of flame retardant, and achieves good flame retardant effect, good expansion performance and short immersion time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

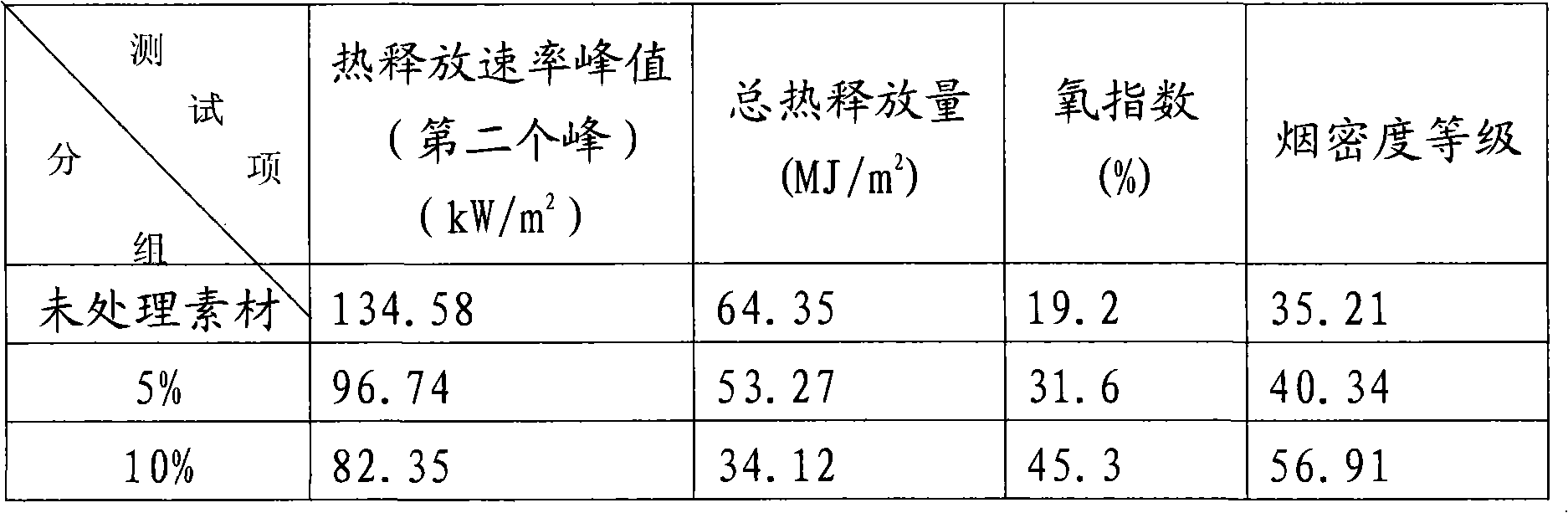

Examples

Embodiment 1

[0022] Add polyphosphoric acid, pentaerythritol, 150ml of solvent methylene chloride, 15g of potassium carbonate in a 500ml three-neck flask equipped with a condensing reflux device according to a molar ratio of 2:1, nitrogen protection, uniform stirring, and heat up to 30°C for 45min, then heat up to React at 50°C for 4 hours, cool, filter with suction, wash with dichloromethane, and dry to obtain cage-shaped phosphate ester powder.

[0023] In water, according to the molar ratio of 2:1, react the caged phosphate ester with melamine phosphate, react at a constant temperature of 60°C for 1 hour, cool, filter, crystallize with glacial acetic acid, and dry to obtain cyclic phosphate powder.

Embodiment 2

[0025] Add polyphosphoric acid, pentaerythritol, solvent dichloromethane 200ml, potassium carbonate 20g according to the molar ratio 3: 1 in the 500ml three-neck flask equipped with condensing reflux device, nitrogen protection, stir evenly, heat up to 50 ℃ and react for 45min, then heat up to React at 85°C for 4 hours, cool, filter with suction, wash with dichloromethane, and dry to obtain cage-shaped phosphate ester powder.

[0026] In water, according to the molar ratio of 2:1, react the caged phosphate ester with melamine phosphate, react at a constant temperature of 70°C for 1 hour, cool, filter, crystallize with glacial acetic acid, and dry to obtain cyclic phosphate powder.

Embodiment 3

[0028] In a 500ml three-necked flask equipped with a condensation reflux device, add polyphosphoric acid, pentaerythritol, solvent methylene chloride 200ml, potassium carbonate 20g according to the molar ratio of 3:1, nitrogen protection, uniform stirring, heat up to 50 ° C for 1 hour, and then heat up to React at 120°C for 4 hours, cool, filter with suction, wash with dichloromethane, and dry to obtain cage-shaped phosphate ester powder.

[0029] In water, according to the molar ratio of 2:1, react the caged phosphate ester with melamine phosphate, react at a constant temperature of 85°C for 1 hour, cool, filter, crystallize with glacial acetic acid, and dry to obtain cyclic phosphate powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com