Flame-retardant impregnated film adhesive facing artificial board and manufacturing method thereof

A technology of impregnating film paper and wood-based panels, which is applied in the field of panel processing, can solve the problems of poor general applicability and processing methods that are not suitable for the flame retardancy of wooden panels, and achieve strong applicability, good flatness, and easy operation. The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

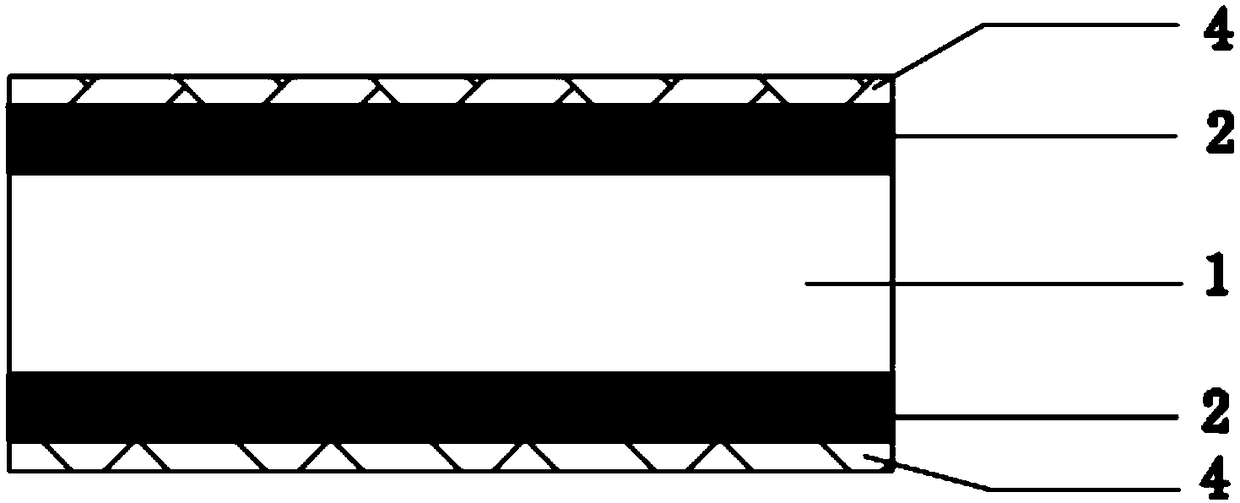

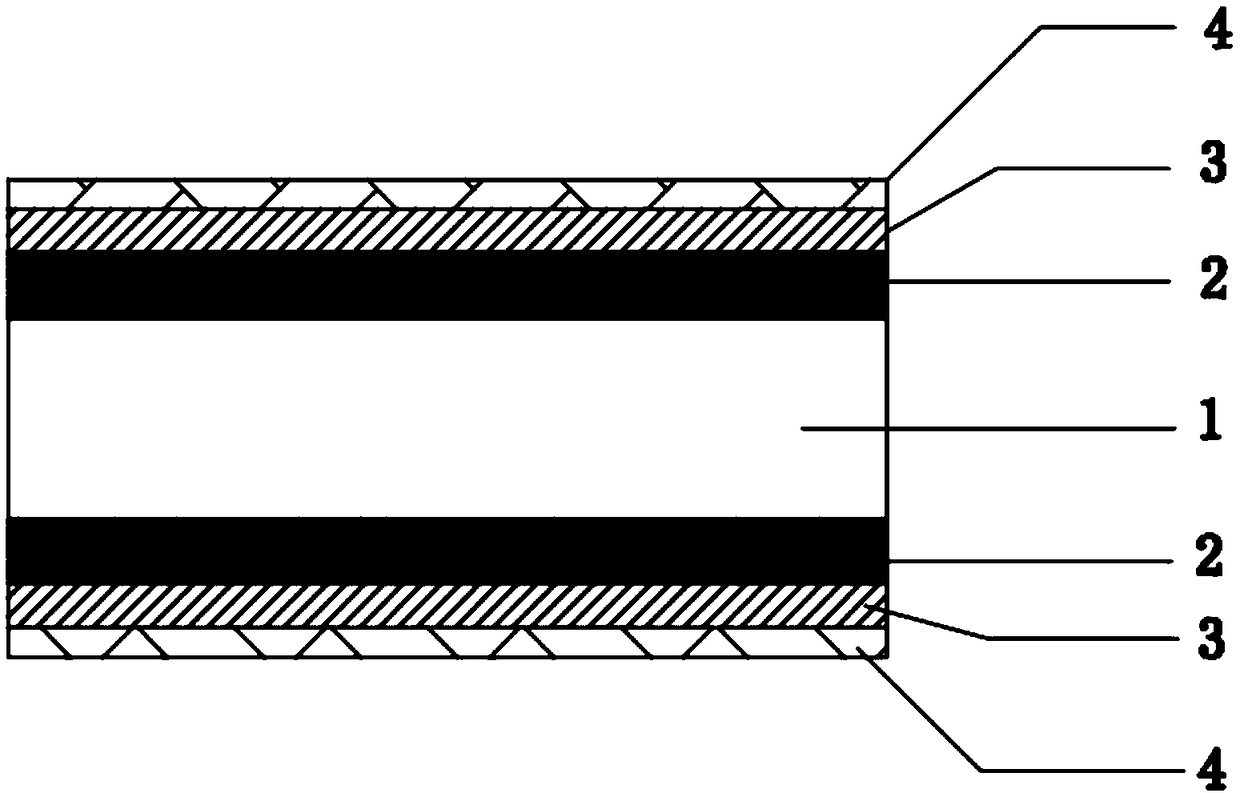

Image

Examples

Embodiment 1

[0059] Embodiment 1 flame retardant dipping method

[0060] S1: Preparation of flame retardant base material, immerse 1.7mm poplar veneer and 0.5mm poplar bark in a uniform aqueous solution of nitrogen, phosphorus and boron flame retardant with a concentration of 25%, the temperature of the flame retardant is 30°C, and the concentration is 25%. Take it out after soaking for 30 minutes, balance the water content to 20% under natural conditions, and dry it to the water content of 8% with a mesh belt dryer.

[0061] S2: Blank assembly, for the flame-retardant poplar veneer after flame-retardant treatment, use amino resin solution at a rate of 400g / m 2 After the glue is distributed, the flame-retardant plywood (17mm) is formed according to the principle of cross-symmetry of odd and even layers, and then a layer of flame-retardant poplar bark with a thickness of 0.5mm is pasted on the upper and lower surfaces of the flame-retardant plywood. 0.4Mpa, temperature 115°C, carry out pre...

Embodiment 2

[0065] Embodiment 2 flame retardant dipping method and flame retardant adhesive method

[0066] S1: Preparation of flame-retardant base material. Immerse 18mm blockboard and 0.5mm poplar veneer in a uniform aqueous solution of intumescent flame retardant with a concentration of 20%. The temperature of the flame retardant is 35°C. Balance the moisture content to 20% under the same conditions, and dry it with a mesh belt dryer to a moisture content of 8%; add a 20% intumescent flame retardant to the adhesive, mix well and stir evenly to obtain a flame retardant containing Adhesive, used for substrate cloth glue assembly, the mass ratio of flame retardant and amino resin solution is 40:100;

[0067] S2: Assemble the billet, use the core strip splicing machine to splice the 18mm flame-retardant blockboard after the flame-retardant treatment, and use the adhesive containing the flame retardant after the splicing is completed, at a rate of 400g / m 2 The amount of cloth glue should b...

Embodiment 3

[0071] Embodiment 3 flame retardant adhesive method

[0072] YA-1: Preparation of flame retardant adhesive, adding a 30% inorganic metal flame retardant to the adhesive, fully mixing and stirring evenly to obtain an adhesive containing flame retardant, which is used for the substrate cloth adhesive group Blank, the mass ratio of described flame retardant and adhesive is 60:100, and described adhesive is amino resin solution;

[0073] YA-2: Preparation of flame retardant core board, mix shavings and flame retardant adhesive in a ratio of 20:3, stir evenly, then pave, pre-press, hot press (pressure 2.5Mpa, temperature 165°C, Time 6min), sawing the edge and 40-100 mesh double-sided sanding treatment to make a flame-retardant core board with a thickness of 16mm;

[0074] YA-3: Blank assembly, use particleboard and high-density fiberboard with a thickness of 0.55mm with an adhesive containing a flame retardant, at 400g / m 2 The amount of glue to be placed is treated with glue, bla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com