Weather-resistant artificial bamboo and wooden board and manufacturing method thereof

A manufacturing method and technology for wood-based panels, which are used in manufacturing tools, bonding of wooden veneers, and impregnating wood, etc., can solve the problem of little application of wood materials, and achieve the effect of preventing the aging process of surface ultraviolet rays.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

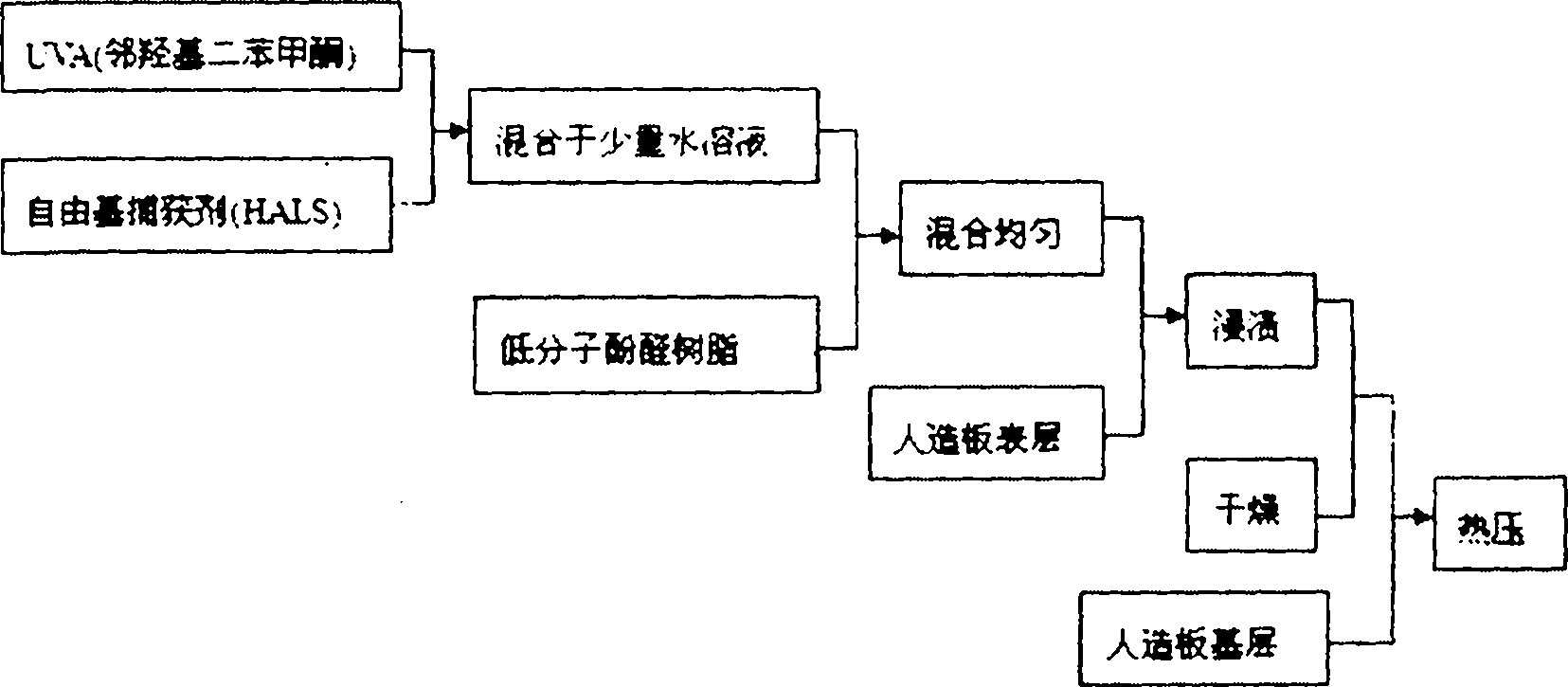

Method used

Image

Examples

Embodiment 1

[0021] Low-molecular phenolic resin (molecular weight: 500-800, viscosity: 15mPas, solid content 38%, concentration diluted to 30% for use), add 2% o-hydroxybenzophenone ultraviolet absorber, 1% free radical scavenger , stir and mix evenly, under normal temperature and pressure, put bamboo fiberized veneer, take it out after soaking for 4-6h, and dry to moisture content of 8-11%. 16%, dried to 8-11% moisture content, billet assembly, hot pressing (hot pressing pressure: 3.5-5.0MPa hot pressing temperature 150-165°C, holding time 30-40min, cooling time 20-35min,), unloading , Trim the edge, and get the finished product.

Embodiment 2

[0023] In the modified urea-formaldehyde resin (viscosity: 30mPas, solid content 35%), add 0.8% o-hydroxybenzophenone ultraviolet absorber, 1% free radical scavengers and 0.5% paraffin, stir and mix evenly. Under normal temperature and pressure, put poplar veneer, soak for 2-4 hours, dry to 7-10% moisture content, dry poplar veneer in the middle layer to 7-10% moisture content, apply glue (glue amount 250- 350g / m 2 ), forming blanks, aging, hot pressing (hot pressing pressure: 0.8-1.2MPa, hot pressing temperature 110-115°C, holding time 10-15min), plate unloading, edge trimming, and finished products.

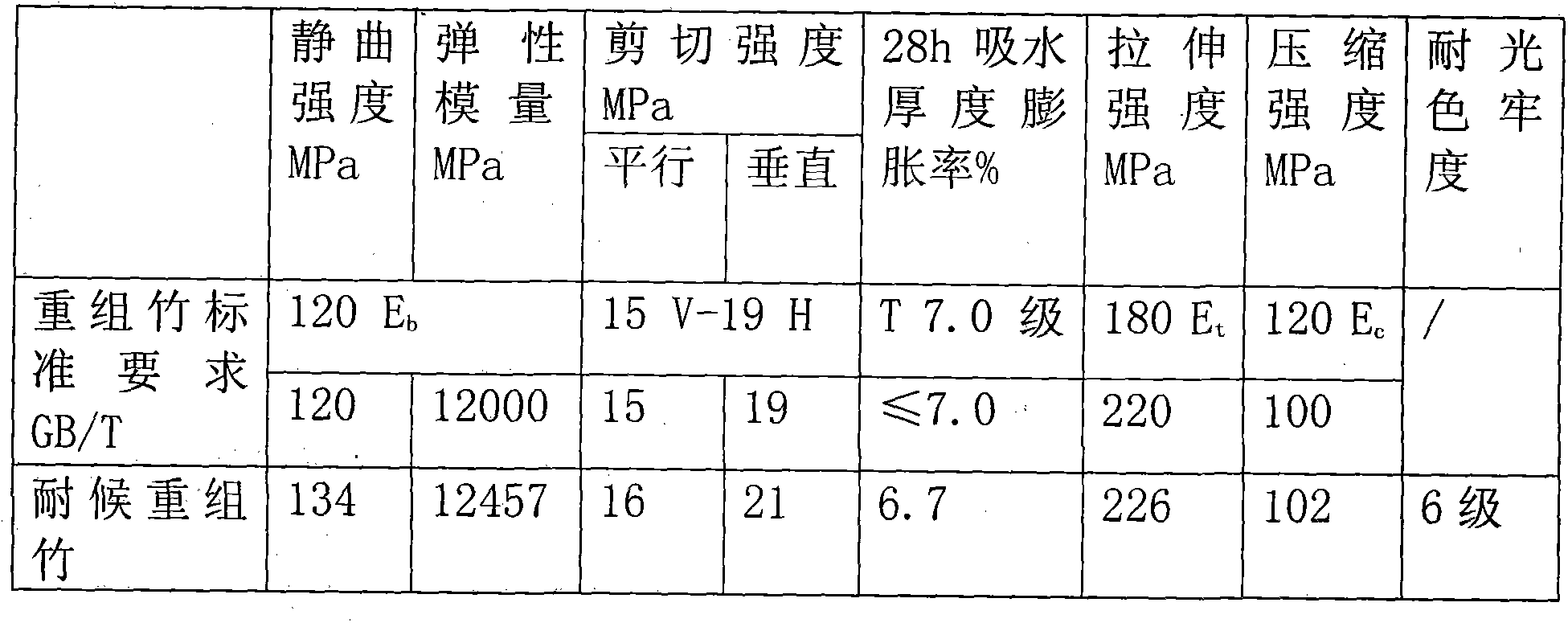

[0024] Table 1 Physical and mechanical properties of weather-resistant recombined bamboo (density: 1.15g / cm 3 )

[0025]

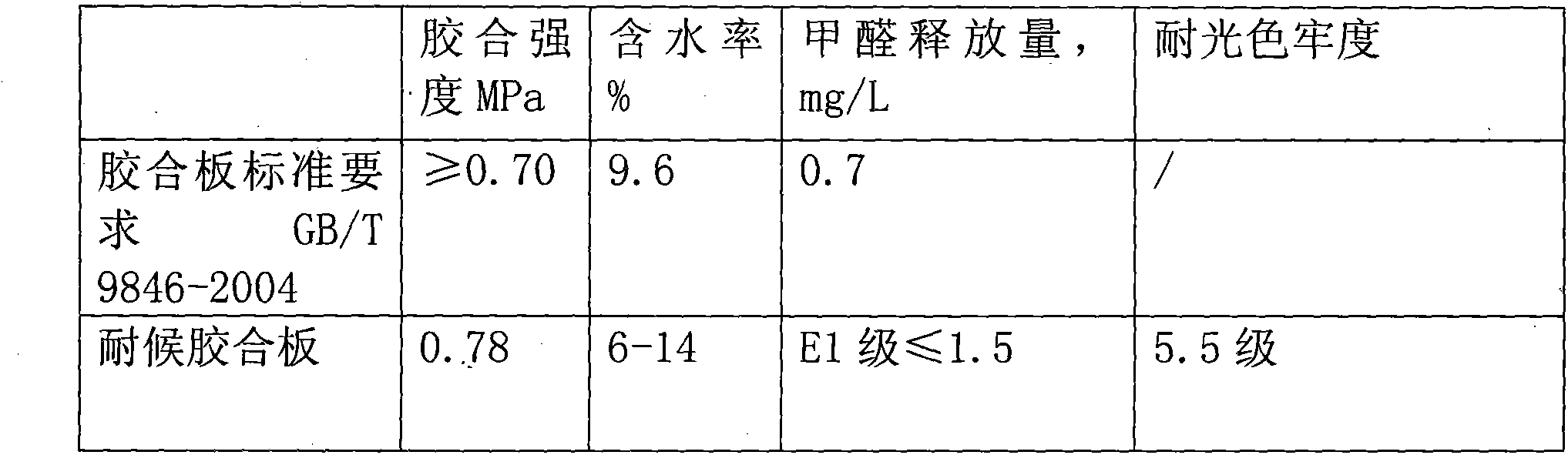

[0026] Table 2 Physical and mechanical properties of weather-resistant recombined bamboo (density: 1.15g / cm 3 )

[0027]

[0028] In summary, as shown in Table 1 and Table 2, the present invention can prevent or slow down the aging process of wood...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com