Anti-corrosion and mothproof treatment method for artificial board blanks after molding

A processing method and slab technology, which is applied in the field of slab processing, can solve the problems of reducing the service life of equipment, dripping of chemicals, waste of chemicals, etc., and achieve the effect of reducing frictional resistance and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

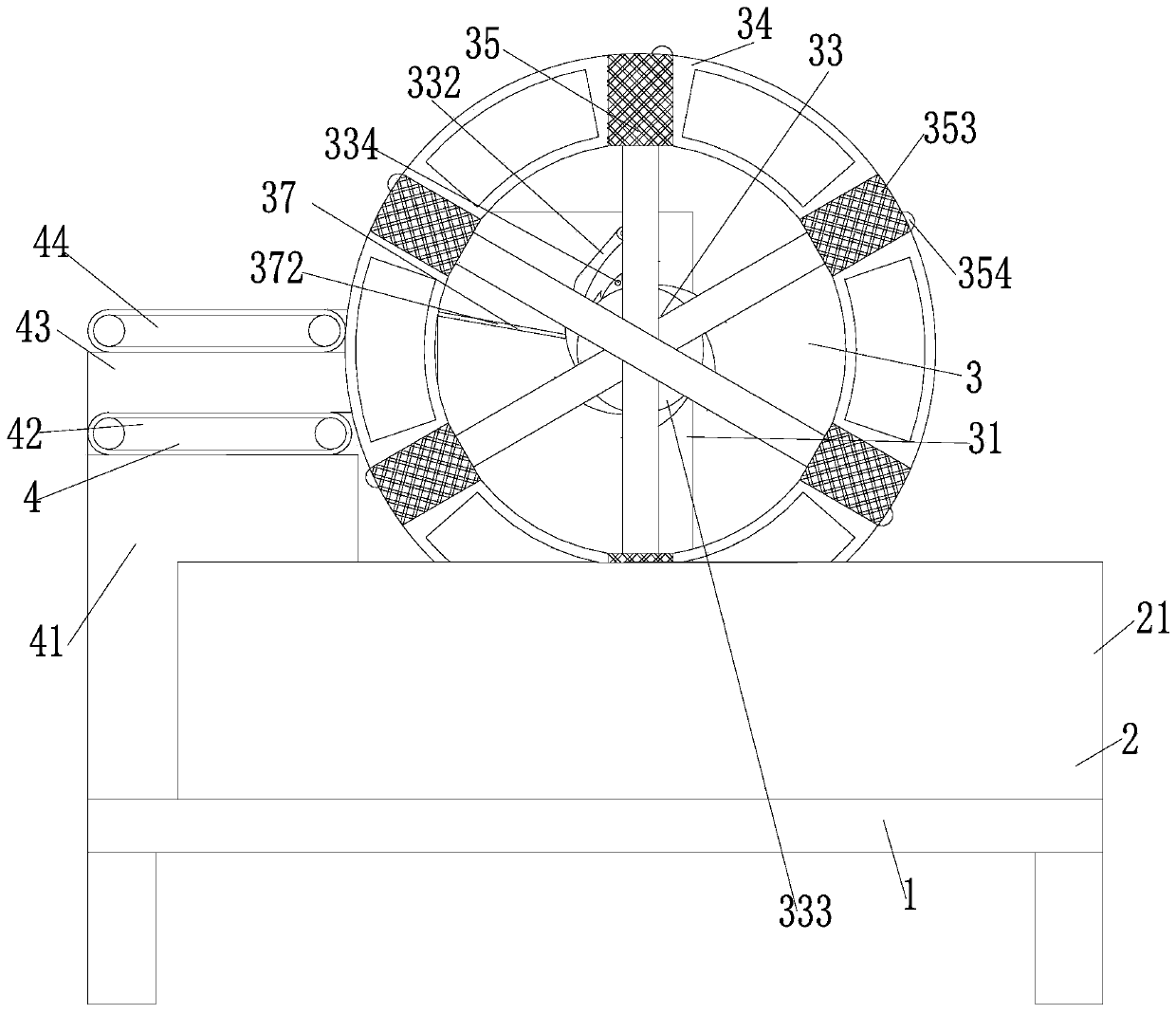

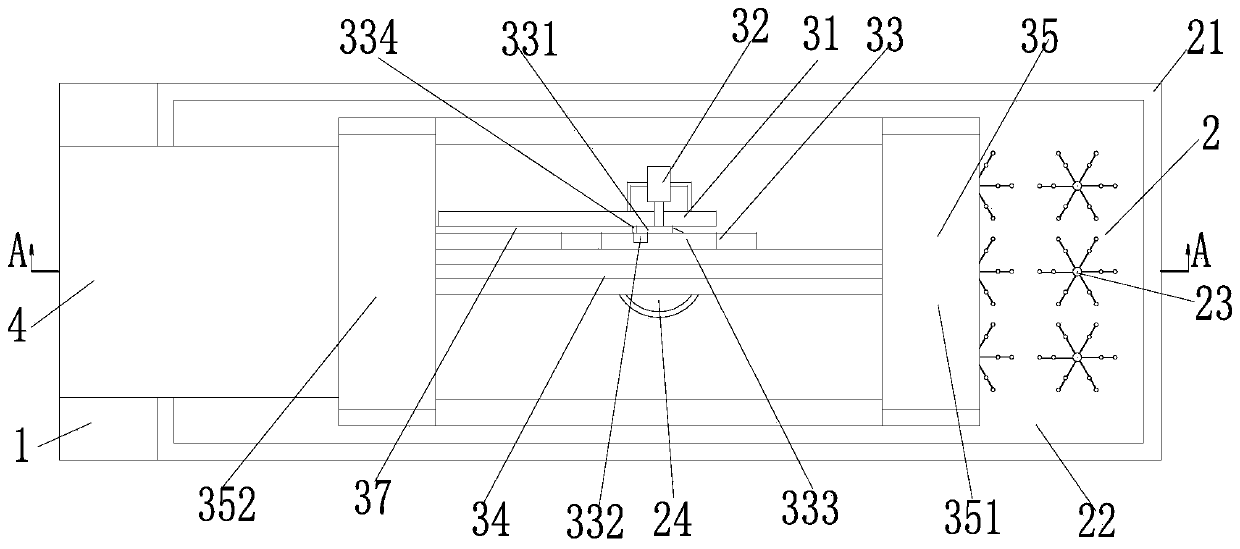

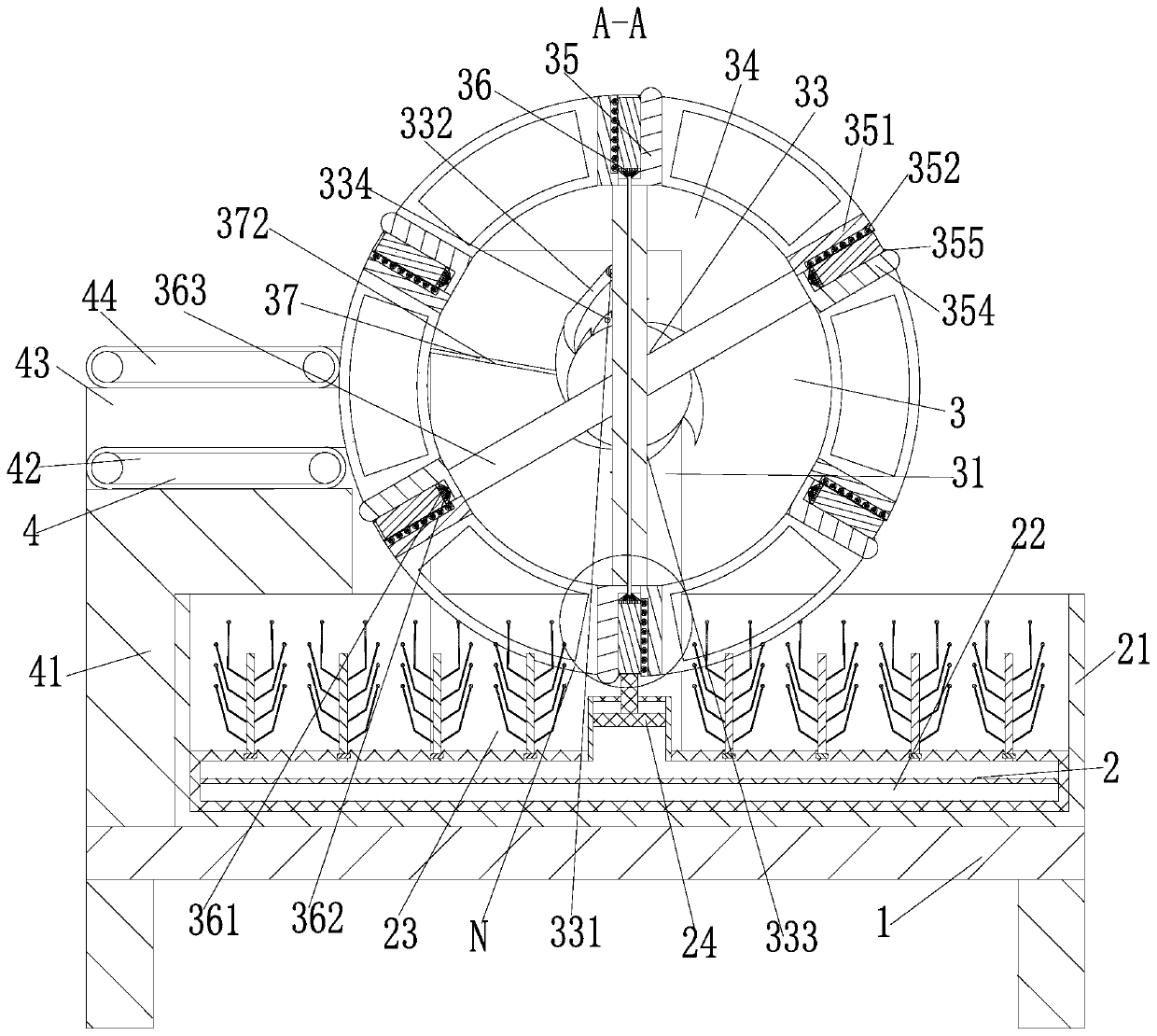

[0040] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 8 , to further elaborate the present invention.

[0041] An anti-corrosion and anti-moth treatment method after forming a wood-based panel slab, which uses anti-corrosion and anti-moth treatment equipment after forming a wood-based panel slab. The rotating device 3 and the transmission device 4 use the above-mentioned anti-corrosion and anti-moth treatment equipment for the artificial board slab to process the artificial board slab as follows:

[0042] S1. Prepare the solvent: configure the solvent according to the ratio, adjust to a suitable temperature, and pour it into the solvent tank 2;

[0043] S2. Fixing the slab: After the solvent is prepared in S1, the slab is transferred to the rotating device 3 through the transmission device 4 for fixing;

[0044] S3, soaking the slab: by moving the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com