Preparation method of glue-free mould pressing artificial board

A technology of wood-based panels and plastic molds, applied in the direction of pretreatment of flat products, manufacturing tools, and molding materials, to achieve the effects of accelerating decomposition and hydrolysis, increasing viscosity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

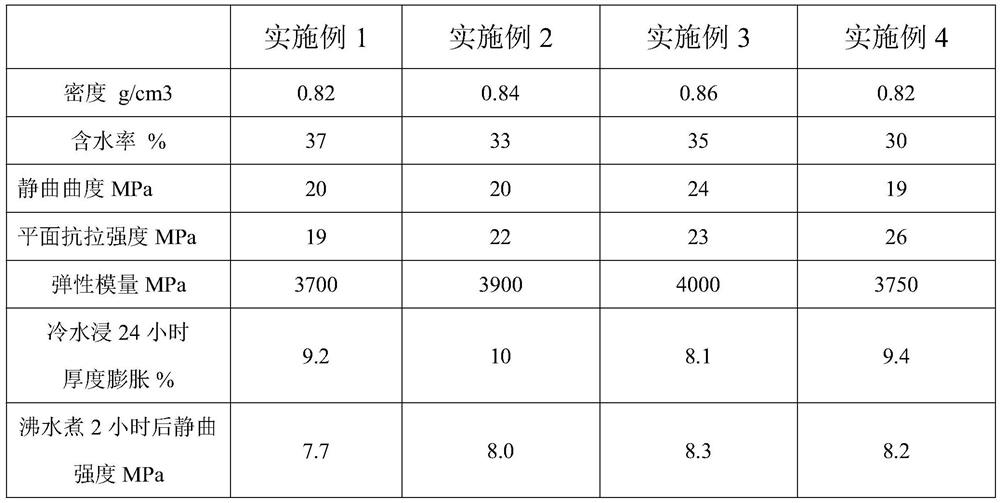

Examples

Embodiment 1

[0025] A method for preparing a glue-free molded wood-based panel, the operation steps are as follows:

[0026] S1: Straw pretreatment: crush wheat straw into 0.1-3cm straw segments, add a mixed solution of cellulase and pectinase with a volume ratio of 1.2, containing cellulase (0.5%) and pectinase (0.5%), at 20°C After soaking for 3 hours, add sodium hydroxide aqueous solution with a volume ratio of 1:1 and a mass fraction of 1% and soak for 2 hours at 20°C;

[0027] S2: Wood pretreatment: crush the wood waste into small pieces with a length ≤ 5cm, a width ≤ 3cm, and a thickness ≤ 2cm for later use;

[0028] S3: High temperature treatment: Add the crushed wood waste described in step S2 into the impregnation solution described in step S1, the mass ratio of wood waste and straw is 1:1, cook at 180°C for 20min, and then dry until the water is 10%.

[0029] S4: pre-press forming: adding the straw mixture described in step S3 to a pre-press, 150°C, 0.8Mpa, pre-press for 5min, ...

Embodiment 2

[0032] A method for preparing a glue-free molded wood-based panel, the operation steps are as follows:

[0033] S1: Straw pretreatment: crush wheat straw into 0.1-3cm straw segments, add a mixed solution of cellulase and pectinase with a volume ratio of 1.2, containing cellulase (0.5%) and pectinase (0.5%), at 20°C After soaking for 3 hours, add sodium hydroxide aqueous solution with a volume ratio of 1:1 and a mass fraction of 1% and soak for 2 hours at 20°C;

[0034] S2: Wood pretreatment: crush the wood waste into small pieces with a length ≤ 5cm, a width ≤ 3cm, and a thickness ≤ 2cm for later use;

[0035] S3: High temperature treatment: Add the crushed wood waste described in step S2 into the impregnation solution described in step S1, the mass ratio of wood waste to straw is 1:1, cook at 180°C for 20min, and then dry until the water is 10%.

[0036] S4: pre-press forming: adding the straw mixture described in step S3 to a pre-press, 160°C, 0.8Mpa, pre-press for 6min, t...

Embodiment 3

[0039] A method for preparing a glue-free molded wood-based panel, the operation steps are as follows:

[0040] S1: Straw pretreatment: crush wheat straw into 0.1-3cm straw segments, add a mixed solution of cellulase and pectinase at a volume ratio of 1.2, containing cellulase (0.5%) and pectinase (0.5%), at 20 degrees Celsius After soaking for 3 hours, add sodium hydroxide aqueous solution with a volume ratio of 1:1 and a mass fraction of 1% and soak for 2 hours at 20°C;

[0041] S2: Wood pretreatment: crush the wood waste into small pieces with a length ≤ 5cm, a width ≤ 3cm, and a thickness ≤ 2cm for later use;

[0042] S3: High temperature treatment: Add the crushed wood waste described in step S2 into the impregnation solution described in step S1, the mass ratio of wood waste to straw is 2:1, cook at 190°C for 15 minutes, and then dry until the water is 10%.

[0043] S4: Pre-press forming: adding the straw mixture described in step S3 to a pre-press, 150°C, 1Mpa, pre-pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com