Method for testing heat release rate of combustible light powder

A technology of heat release rate and testing method, which is applied in the field of measurement and evaluation of material heat release rate, can solve the problems of large deviation of test results and lack of combustion performance of combustible light powder, so as to improve scientificity, increase minimum ignition energy, The effect of reducing the likelihood of an explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment provides a test method for the heat release rate of combustible light powder, the steps are as follows:

[0026] Step 1, select a grain flour sample, sieve out a powder with a fineness of 80-85 mesh, take 200g and place it in an oven, and dry it at 60°C for 1 hour;

[0027] Step 2, according to the density of the test sample, weigh 2.0g of the sample and load it into the bottom surface of 20×20mm 2 The steel columnar molding equipment is pressed into the mold, the compressive strength is 0.2MPa, the pressure increase rate is 0.05MPa / min, and the pressure is maintained for 3 minutes; the pressure is released and the sample is demoulded to form a square sample with a thickness of 5mm.

[0028] Step 3: After preheating, calibrating and setting the radiation intensity of the cone calorimeter according to the regulations, cover the inner groove of the sample holder with aluminum foil, arrange 25 samples neatly, and lay them flat in the inner groove of the sam...

Embodiment 2

[0031] This example provides a test method for the heat release rate of combustible light powders:

[0032] Step 1, the sieving fineness is 100~120 orders, other is the same as embodiment 1;

[0033] Step 2, adding 2% starch, pressing at 0.4MPa to form a square sample with a thickness of 2mm, the others are the same as in Example 1;

[0034] Step 3, with embodiment 1;

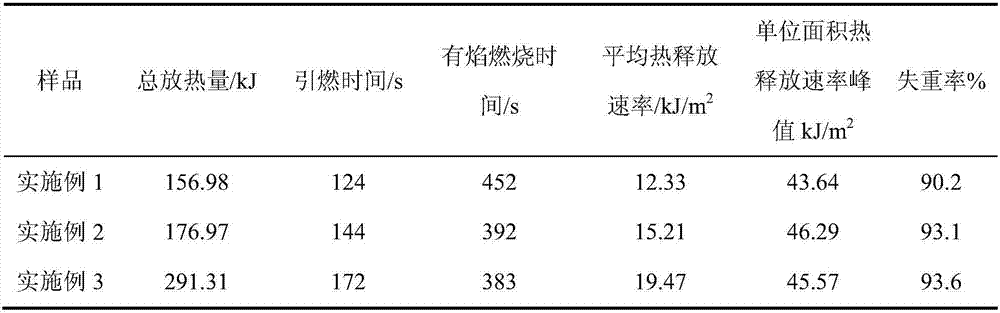

[0035] The experimental results of the heat release rate of the tested cereal flour are shown in Table 1.

Embodiment 3

[0037] This example provides a test method for the heat release rate of combustible light powders:

[0038] Step 1, the sieving fineness is more than 140 orders, and others are the same as embodiment 1;

[0039] Step 2, forming a square sample with a thickness of 3.5mm, others are the same as in Example 1;

[0040] Step 3 is the same as in Example 1.

[0041] The experimental results of the heat release rate of the tested cereal flour are shown in Table 1.

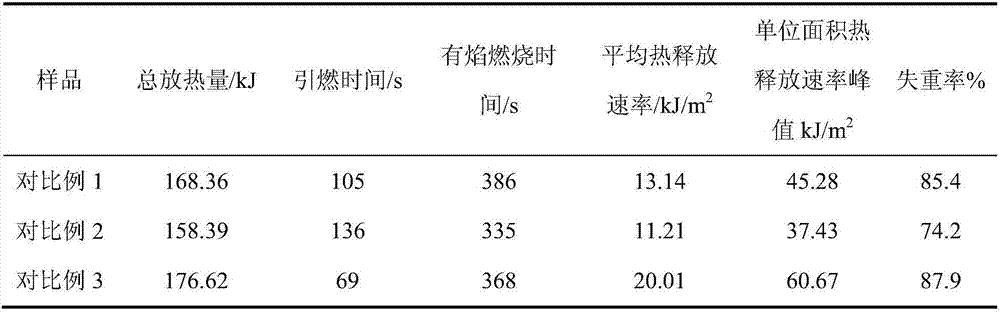

[0042] Table 1 shows the experimental results of testing the heat release rate of grain flour in three examples. It can be seen that the smaller the grain size of the grain flour, the longer the ignition time, the more total heat release, the greater the average heat release rate, and the longer the flame burning time. Short, but the peak heat release rate per unit area does not change much, and the greater the weight loss rate, it indicates that the material burns more fully.

[0043] Table 1 Heat release rate of three...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com