Rubber wood protective method

A technology for rubber wood and wood, applied in pressure impregnation and other directions, can solve the problems of wood not growing mildew, discoloration fungus damage, highly toxic aquatic organisms, etc., and achieve the effects of simple dispensing operation, good protection effect, and low cost of pharmaceuticals

Inactive Publication Date: 2002-01-02

中南(海南)橡胶木材傢俱厂

View PDF0 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This technology has a certain protective effect on rubber wood, but has the following defects: 1. In general, there will be no insects, but sometimes part of the wood will be eaten by bark beetles during the drying period. Many small wormholes are left; 2. During the drying period, most of the wood will not grow mold, and a few will grow mold spots

The color of the inner layer of discolored wood is normal from the surface, but after sawing, it will reveal blue-black color (called "blue discoloration", which is the result of damage caused by discoloration bacteria), and the appearance of furniture and other products made of such wood cannot maintain rubber The natural color and luster of wood, the natural beauty is poor, does not meet the mentality needs of contemporary consumers who advocate returning to nature, the market competitiveness is not strong, sales and selling prices are affected, and the operators suffer economic losses; 4. The chemicals used Toxicity: Both borax and boric acid have no peculiar smell, and the toxicity to humans and animals is low to slightly toxic and slightly toxic respectively, with little damage to the environment

However, sodium pentachlorophenate has a pungent odor, is moderately toxic to humans and animals, is highly toxic to aquatic organisms, and seriously pollutes the environment. Some countries and regions have banned or restricted its use.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

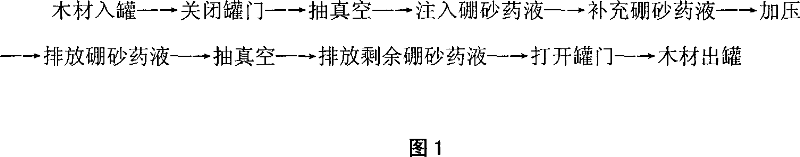

An environment-protecting type rubber wood protection (pest-resisting and fungi-resisting) method is characterized by using 2.5%-5.0% borax liquor to implement vacuum pressure treatment of fresh rubber wood, and when the said wood is treated, the used vacuum degree is -0.07--0.09 MPa, pressure is 1.1-1.3 MPa, the pressurizing time is dependent to the thickness of wood, and the pressurizing time of 3.0-8.5 cm thickness is 30-70 min. After the wood is treated, it can be prompty stached and dried in the air for 8-12 days, then dried in drying kiln to make its water content be reduced to 10%-8%. The wood treated by the said invention can prevent moth damage, and does not produce blue stain, so it is suitable for making furniture, and its used chemical preparation is low in toxicity, and low in cost, and its preparation is simple.

Description

Technical field: The invention relates to an environment-friendly rubber wood protection (insect and bacteria prevention) method, which belongs to the technical field of wood protection. technical background: Rubberwood refers to rubber tree wood. The rubber tree is a tall tropical tree, which is widely planted as a cash crop in Indonesia, Thailand, Malaysia, India, Vietnam, the Philippines, Cambodia, Sri Lanka and South China and other tropical regions because of its ability to produce natural rubber. The main product of the rubber plantation industry is natural rubber, and the by-product is rubber wood. Rubber wood is uniform in texture, elegant in color, delicate in pattern, moderate in weight, hardness, strength and toughness, easy to dry, small in deformation, and good in machining performance. But it is easy to be attacked by insects, molds and discoloration bacteria, etc., and its natural life is very short, and it loses its use value in only about one year. Ther...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B27K3/08

Inventor 陈达志朱明磊李粤阎新发

Owner 中南(海南)橡胶木材傢俱厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com