Method for processing blue-stain wood

A treatment method, the technology of blue change, applied in wood treatment, wood treatment details, wood processing equipment, etc., can solve the problems affecting the post-processing performance of wood paint, little prospect, long treatment time, etc., to improve the appearance quality, Improve the application prospect and market value, the effect of uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] This embodiment is used to illustrate the processing method of the blue stained wood provided by the present invention.

[0021] Choose Canada to produce, length is 4000mm, thickness is 40mm the blue-changed twisted leaf pine (pinuscontorla) sheet material, water content is 10% by weight, and blue-change rate (being the percentage of the area of blue-change part accounted for the total surface area of plate) is 30 area% , the color of the blue-change part is dark blue, CIE L * a * b * color value L * Value 78.107, a * value -1.215, b * Value 24.785, CIE L of the non-blue-colored part * a * b * color value L * value 81.025, a * Value 1.832, b * Experiment with a value of 30.481.

[0022] The above board was sawed into 6 test bodies with a length of 500mm, a width of 90mm, and a thickness of 40mm. Among them, 3 test bodies had no blue stain, and the remaining 3 test bodies were partially or completely blue stained. The above-mentioned experimental body was...

Embodiment 2

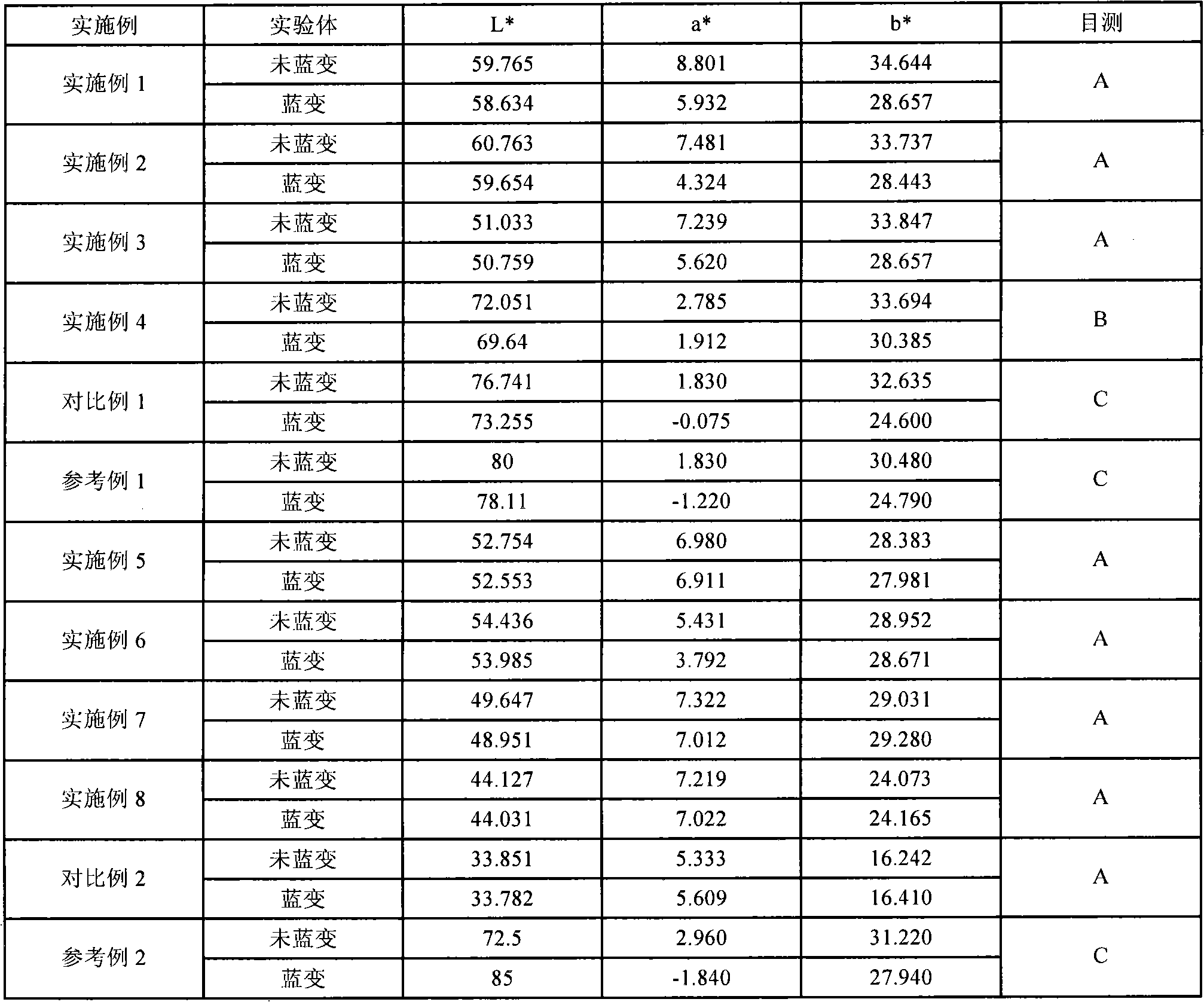

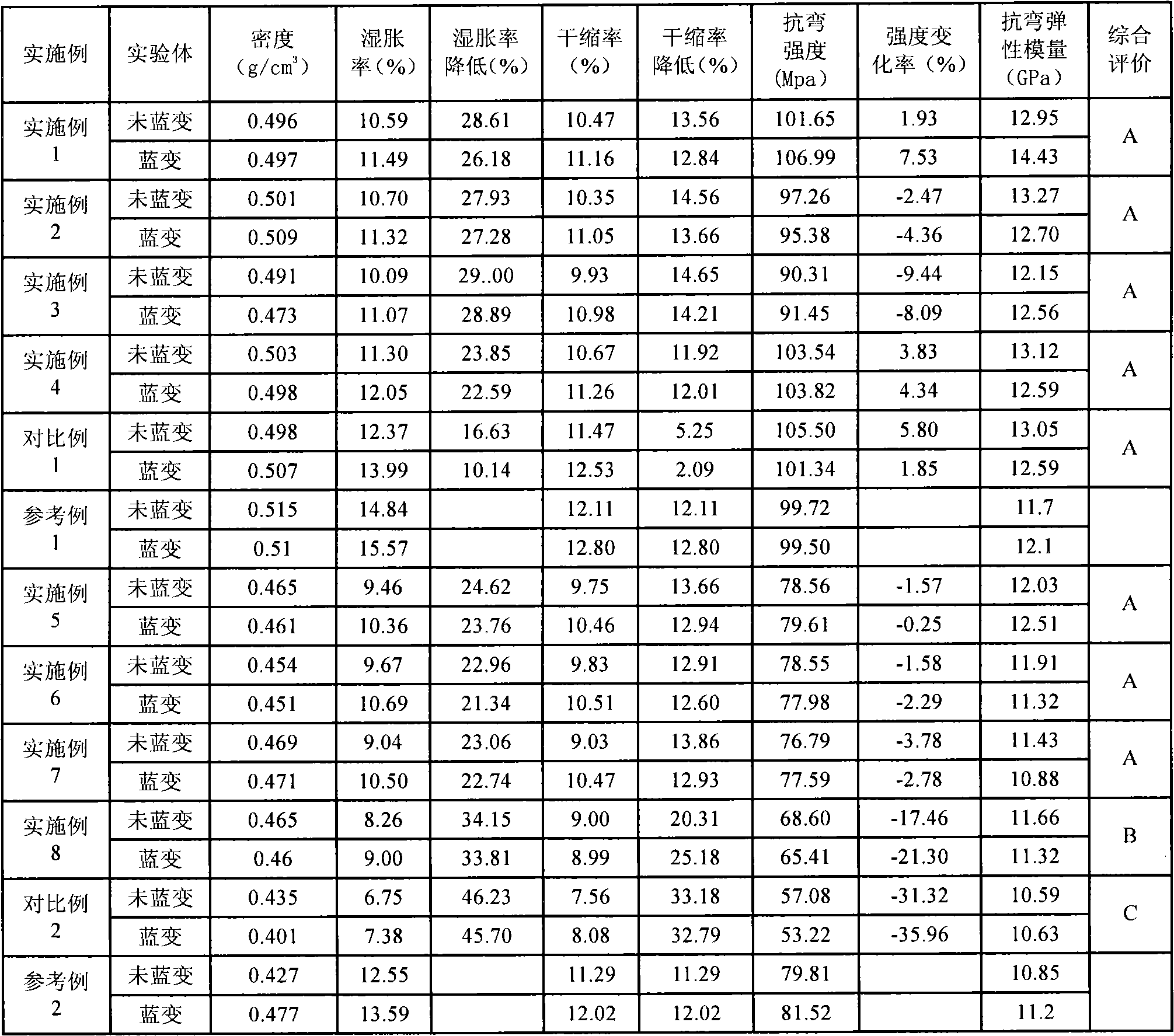

[0024] According to the method of embodiment 1, the heat treatment is carried out to the blue twisted pine plate (the source is the same as that of embodiment 1), the difference is that the heating temperature is 205 ℃, and the heating time is 4 hours, and the CIE L of the wood after heat treatment * a * b* The color value was tested with a Minolta CR-300 color measuring device, and the results are shown in Table 1. Density, volume expansion rate, volume dry shrinkage rate, flexural strength, and flexural modulus of elasticity are carried out using Chinese national standard GB / T1931-1936-2009. The results are shown in Table 2. The values of each indicator in Table 1 and Table 2 are average values.

Embodiment 3

[0026] This embodiment is used to illustrate the processing method of the blue stained wood provided by the present invention.

[0027] Choose Canada to produce, length is 4000mm, thickness is 40mm the blue twisted lobe pine (pinuscontorla) sheet material, water content is 13% by weight, and blue change rate (being the percentage of the area of blue change part accounted for the total surface area of plate) is 50 area% . The color of the blue-changed part is dark blue, CIE L * a * b * color value L * Value 74.61, a * value -1.42, b * Value 21.02, CIE L of the non-blue part * a * b * color value L * Value 77.84, a * Value 0.83, b * Experiment with a value of 26.40.

[0028] The above board was sawed into 6 test bodies with a length of 500mm, a width of 90mm, and a thickness of 40mm. Among them, 3 test bodies had no blue stain, and the remaining 3 test bodies were partially or completely blue stained. The above-mentioned experimental body was placed in a closed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com