Organosilicon reinforced composite type oil phase dispersed demulsifying agent

An organosilicon and demulsifier technology, applied in the direction of chemical dehydration/demulsification, etc., can solve the problems of high cost and cannot be completely replaced, and achieve the effect of reducing usage, less oil in drainage, and improving broad-spectrum.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

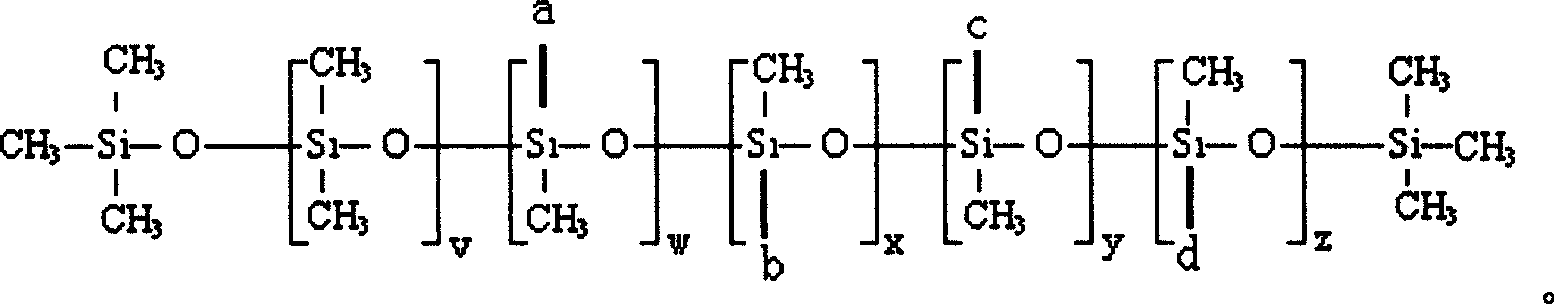

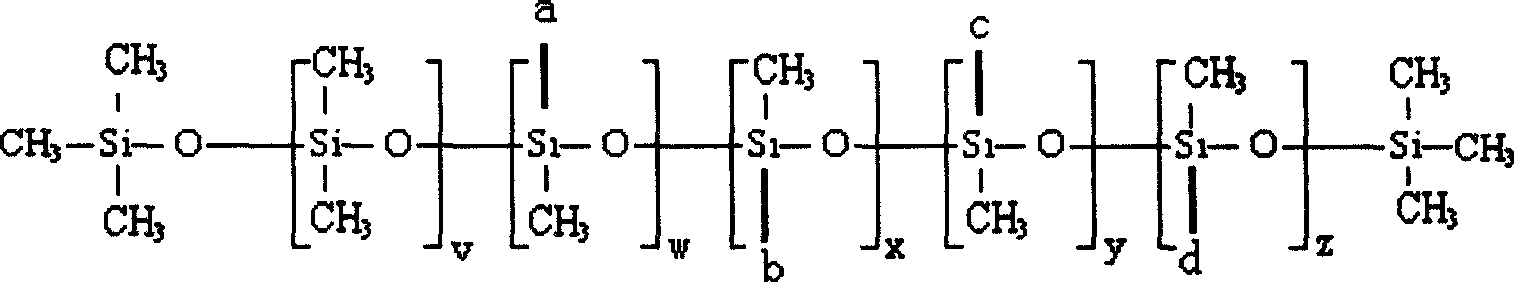

Method used

Image

Examples

Embodiment A

[0027] Composite demulsifier composition: silicone demulsifier (grade: 321), 10%; non-silicon demulsifier AP221, 15%; non-silicon demulsifier AR36, 25%; dodecylbenzenesulfonic acid, 0.5%; Mixed xylene solvent, 39.5%; hydrocarbon solvent naphtha 200#, 10%. The silicone-based reinforced composite oil phase dispersion demulsifier formed by compounding is compared with the mixed crude oil emulsion of Liaohe: Daqing = 70:30 (weight ratio) at 80 ° C. The comparison table below shows the dehydration efficiency.

[0028]

[0029]

Embodiment B

[0031] Organosilicon-based enhanced composite oil phase dispersion demulsifier composition: silicone demulsifier (brand: 606), 5%; non-silicon demulsifier BP2040, 10%; non-silicon demulsifier AR46, 35%; dodecyl Benzenesulfonic acid, 0.5%; Aromatic solvent, 44.5%; Isopropanol, 5%. The dehydration efficiency of the compounded demulsifier to the mixed crude oil emulsion of Shengli crude oil and Oman crude oil at 85°C is compared in the following table.

[0032]

Embodiment C

[0034] Silicone reinforced compound oil phase dispersion demulsifier composition: silicone polymer demulsifier (brand: 1636), 8%; non-silicon demulsifier AE0604, 10%; non-silicon demulsifier BP2070, 5%; non-silicon Demulsifier ZR101, 32%; dodecylbenzenesulfonic acid, 0.6%; mixed aromatic solvent, 34.4%; isopropanol, 5%; methanol, 5%. The dehydration efficiency of the compounded demulsifier against a light Sudanese crude oil (higher acid value) at 65°C is compared in the following table.

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com