Food-grade antibacterial antistatic PLA material and preparation method thereof

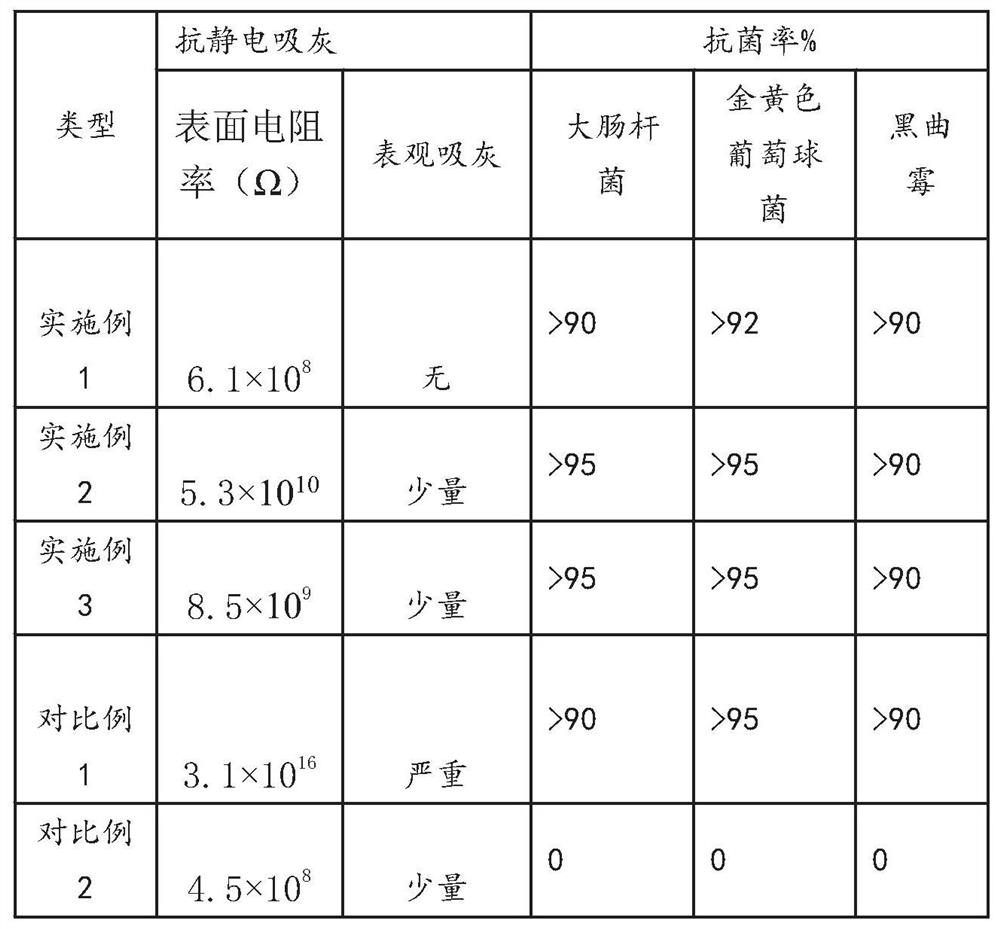

A food-grade, anti-static technology, applied in the field of food-grade antibacterial and antistatic PLA materials and preparation, can solve the problems of easy electrostatic ash absorption, poor antibacterial performance of polylactic acid film, affecting the hygiene of packaged food, etc., and achieves good antibacterial effect. The effect of good capacitance and excellent antistatic dust removal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] S1, put 60 parts of PLA resin, 20 parts of PBAT, and 3 parts of glycidyl methacrylate into a high-speed mixer and stir for 3-5 minutes;

[0026] S2, 15 parts of talcum powder, 3 parts of antistatic agent, 1 part of zinc borate, 5 parts of chitosan, 2 parts of EBS are dropped into high-speed mixer and stirred for 3-5min;

[0027] S3. Add the S1 mixture into the twin-screw extruder through the main feeding hopper, and add the S2 mixture into the twin-screw extruder through the side feeding hopper, and then melt, extrude, pelletize, and dry to obtain pellets.

[0028] Among them, the barrel temperature of the twin-screw extruder is 150°C, the screw speed is 350r / min, and the main engine frequency is 18Hz.

Embodiment 2

[0030] S1, 70 parts of PLA resin, 10 parts of PBAT, 5 parts of maleic anhydride graft compatibilizer are dropped into high-speed mixer and stirred for 3-5min;

[0031] S2. Put 5 parts of calcium carbonate, 0.5 parts of antistatic agent, 3 parts of zinc borate, 3 parts of zinc oxide, 1 part of magnesium oxide, 7 parts of tea polyphenols, and 1 part of calcium stearate into a high-speed mixer and stir for 3-5 minutes ;

[0032] S3. Add the S1 mixture into the twin-screw extruder through the main feeding hopper, and add the S2 mixture into the twin-screw extruder through the side feeding hopper, and then melt, extrude, pelletize, and dry to obtain pellets.

[0033] Among them, the barrel temperature of the twin-screw extruder is 210°C, the screw speed is 450r / min, and the main engine frequency is 20Hz.

Embodiment 3

[0035] S1. Put 50 parts of PLA resin, 15 parts of PBAT, and 4 parts of silane coupling agent into a high-speed mixer and stir for 3-5 minutes;

[0036] S2. Put 5 parts of diatomite, 1 part of antistatic agent, 1 part of magnesium oxide, 0.5 part of silver powder, 10 parts of chitosan, 8.5 parts of tea polyphenols, and 1.5 parts of glyceryl monostearate into a high-speed mixer and stir for 3 -5min;

[0037] S3. Add the S1 mixture into the twin-screw extruder through the main feeding hopper, and add the S2 mixture into the twin-screw extruder through the side feeding hopper, and then melt, extrude, pelletize, and dry to obtain pellets.

[0038] Among them, the barrel temperature of the twin-screw extruder is 200°C, the screw speed is 400r / min, and the main engine frequency is 19Hz.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com