Preparation method of layered unsaturated silver-zinc-copper-loaded composite antibacterial antiviral agent

A compound antibacterial and unsaturated technology, applied in the fields of botanical equipment and methods, disinfectants, chemicals used for biological control, etc., can solve the problems of insufficient antiviral performance and poor stability, and achieve easy oxidation and discoloration. , long service life, enhanced broad-spectrum effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

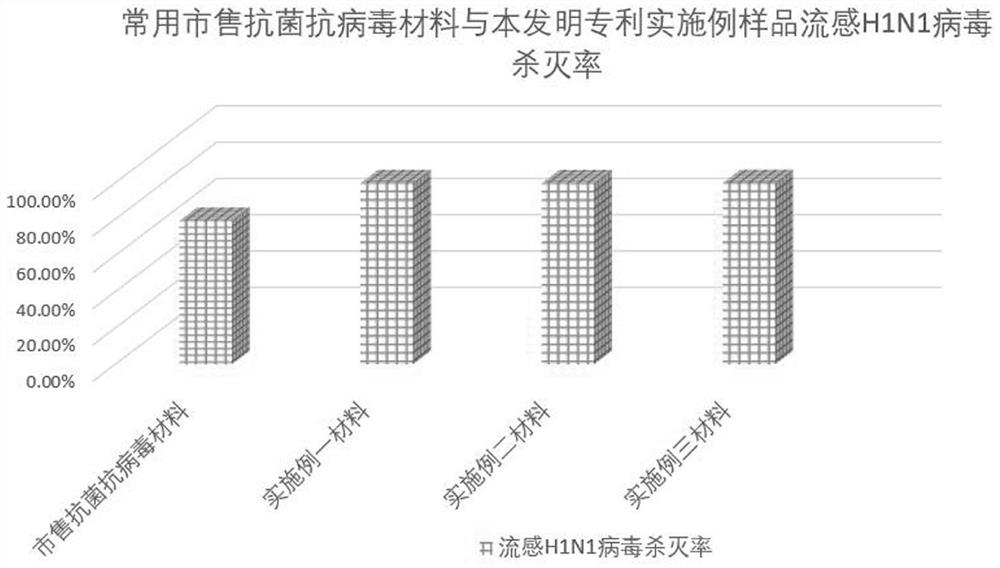

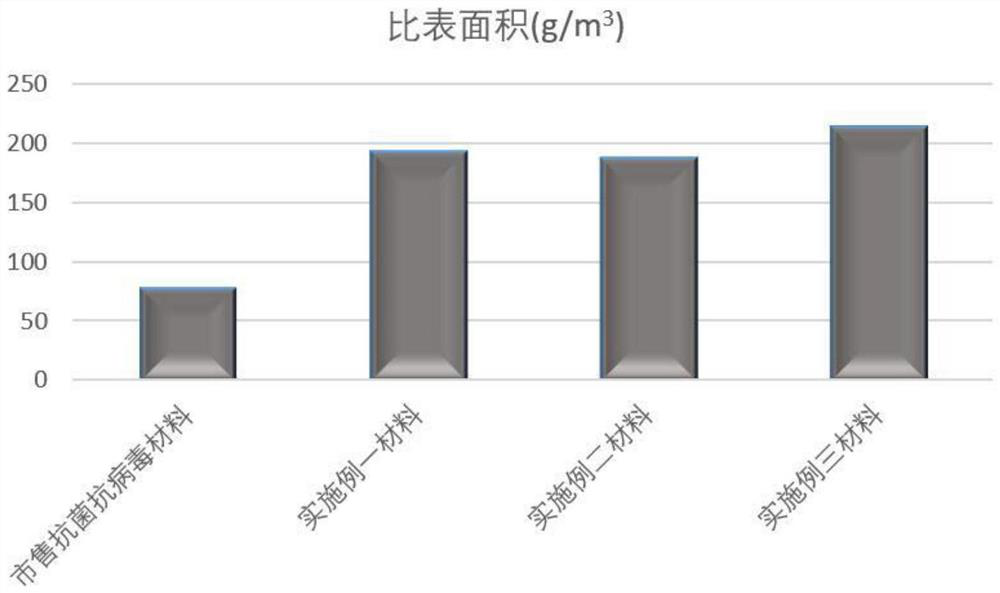

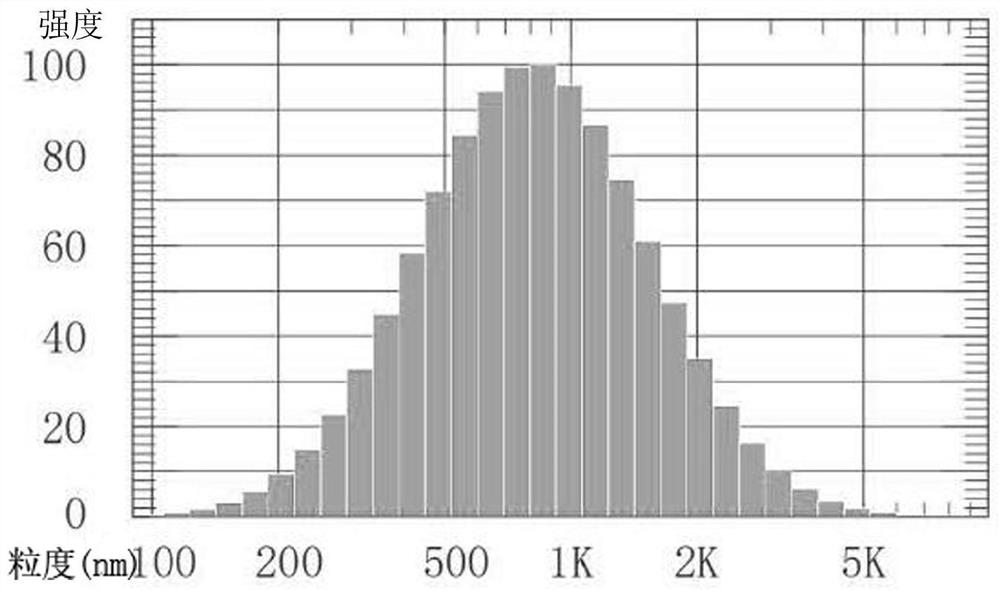

Embodiment 1

[0030]Take by weighing inorganic silver salt, zinc salt, copper salt, modifier, complexing agent and solvent (silver salt is silver nitrate; Zinc salt is zinc chloride; Copper salt is copper sulfate; Solvent is deionized water; Silver salt and The mass ratio of the solvent is 1:1; the mass ratio of the silver salt to the zinc salt is 1:0.01; the mass ratio of the silver salt to the copper salt is 1:0.01; the modifier is aminotriacetic acid; the complexing agent is benzo- 15-crown ether-5, the mass ratio of silver salt, complexing agent and modifier is 1:0.01:0.01), at first silver salt, zinc salt, copper salt, complexing agent and modifier are added in the solvent, Adopting ultrasonic (power is 1000W) assisted high-speed shearing (rotating speed is 5000 rev / min, treatment time is 0.5h) stirring mode is carried out modification to metal ion, obtains modified metastable complexed silver-zinc-copper ion solution; The two-dimensional nano-layered material (the two-dimensional nano...

Embodiment 2

[0032] Take by weighing inorganic silver salt, zinc salt, copper salt, modifier, complexing agent and solvent (silver salt is silver chlorate; Zinc salt is zinc carbonate; Copper salt is cupric chloride; Solvent is ethanol; Silver salt and solvent The mass ratio of silver salt and zinc salt is 1:20; the mass ratio of silver salt and copper salt is 1:30; the modifier is potassium sodium tartrate; the complexing agent is diethylenetriamine Pentaacetic acid, the mass ratio of silver salt, complexing agent and modifier is 1:50:50), at first silver salt, zinc salt, copper salt, complexing agent and modifier are added in the solvent, adopt ultrasonic (power 3000W) assisted high-speed shearing (rotating speed is 15000 rpm, treatment time is 3h) stirring mode to modify the metal ions to obtain a modified metastable complexed silver-zinc-copper ion solution; the two-dimensional nano-layered The material (the two-dimensional nano-layered material is graphite-like carbon nitride. The mas...

Embodiment 3

[0034] Take by weighing inorganic silver salt, zinc salt, copper salt, modifier, complexing agent and solvent (silver salt is silver bicarbonate; Zinc salt is zinc acetate; Copper salt is copper nitrate; Solvent is Virahol; Silver salt and The mass ratio of the solvent is 1:300; the mass ratio of the silver salt to the zinc salt is 1:5; the mass ratio of the silver salt to the copper salt is 1:2; the modifier is dithizone; the complexing agent is PN methylol Sodium base sulfonate, the mass ratio of silver salt, complexing agent and modifier is 1:100:100), at first silver salt, zinc salt, copper salt, complexing agent and modifier are added in the solvent, adopt ultrasonic (Power is 8000W) Auxiliary high-speed shearing (rotational speed is 30000 rev / min, treatment time is 10h) stirs the way to modify the metal ion, obtains the modified metastable state complexed silver-zinc-copper ion solution; the two-dimensional nano The layered material (the two-dimensional nano-layered mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com