Multistage bag-type compression anchor bar

An extrusion-type and bolt-rod technology, applied in the installation of anchor rods, sheet pile walls, excavation, etc., can solve the problems of large loss of cement slurry, reduced anchor pull-out force, poor anchoring effect, etc. The effect of improving pullout resistance and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

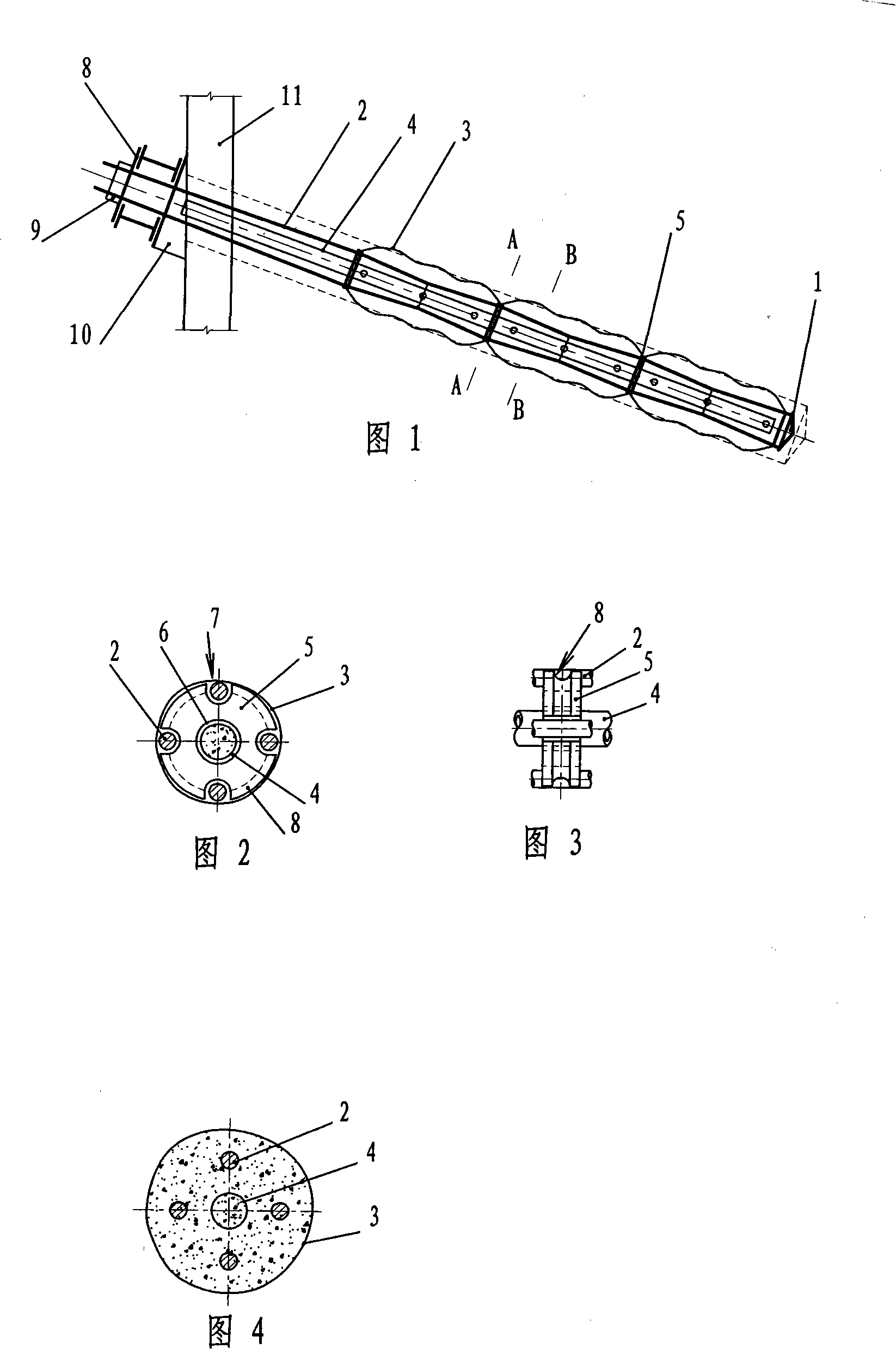

[0014] Referring to Figures 1 to 4, the embodiment shown in the present invention includes an anchor rod body 2 that is fixedly connected to the guide head 1 at one end, and the anchor rod body 2 is bound together by four steel bars or steel strands. The anchoring section of 2 is covered with a tubular fabric bag 3, the length of which is 6 meters to 15 meters, and the diameter of the fabric bag 3 is 5 cm to 10 cm larger than the diameter of the anchor rod drilling; the lower port of the fabric bag 3 at the end of the guide head 1 is used directly The lace is tied tightly with the anchor rod body 2, and the sealing support 5 is installed on the anchor rod body 2 at the upper port of the fabric bag 3, and the fabric bag 3 and the anchor rod body 2 are bound and tightened with a tie; on the fabric bag 3 , and on the anchor rod body 2 between the lower ports, sealing brackets 5 are also installed at intervals of 2.0 to 3.0 meters, and the fabric bag 3 and the anchor rod body 2 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com