Bag expansion diameter-variable steel reinforcement cage and anchor rod or pile foundation

A steel cage, variable diameter technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

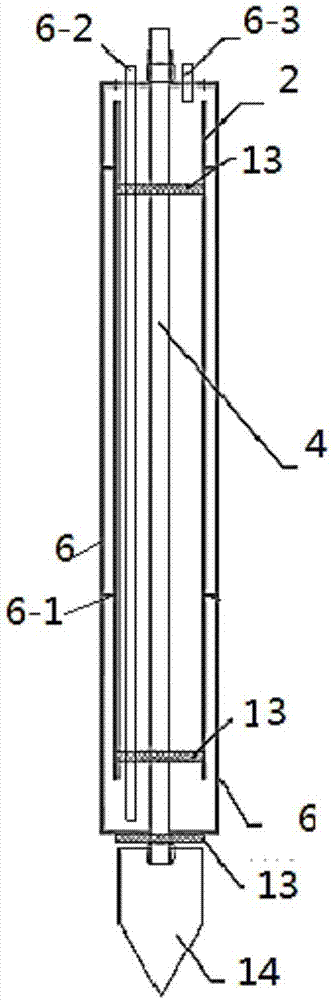

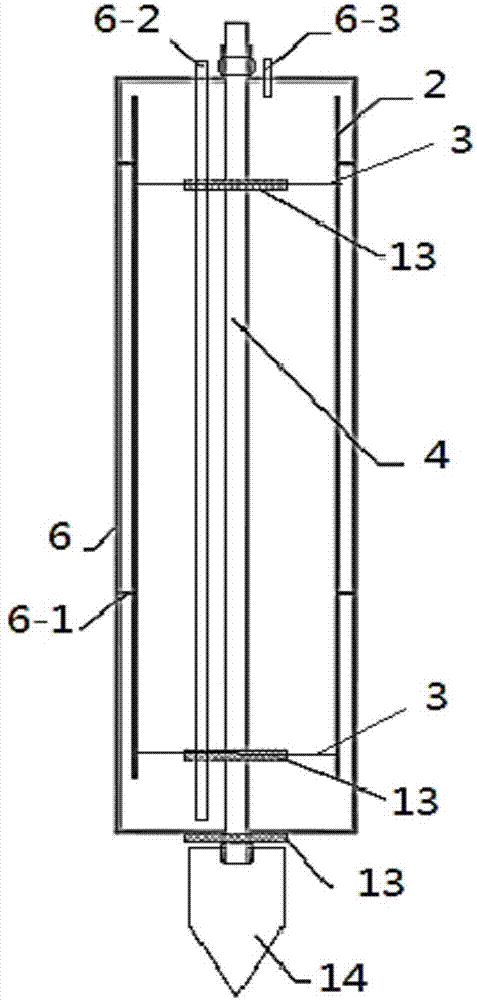

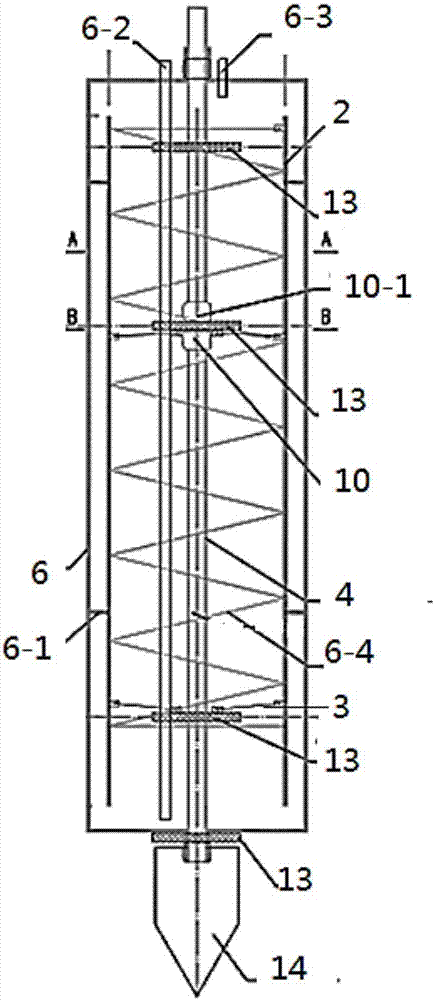

[0054] The basic structure of the present invention is as Figure 1-2 Shown: As shown in the parts in the figure, the axial rod (high-strength tensile steel bar or steel pipe) 4 (the axial spring can be set on the axial rod), a ring or ring plate, several vertical ribs 2, ribs 3, ring-shaped fixer 5, stirrup 6-4, pouch 6, connection strip 6-1 between pouch and vertical bar 2, connection point between stirrup and axial rod 4, (ring) stirrup steel sleeve Socket for ring fit, welding of steel tray and steel pipe, counterweight, limiter 10-1, steel tray (i.e. ring-shaped fixer) 13, rib 3 can be a flat bar; pin bracket (U-shaped fixed bracket) 3-1. Check valve 6-3. Connecting bar 6-1 can also be other fixing methods, as being fixed with fabric pocket etc. on the pouch.

[0055] Capsular bag expansion: cement slurry is poured into the variable-diameter steel cage for bladder bag expansion, and the grouting outer pipe 6-2 is connected to perform expansion grouting of the capsule b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com