Inclined type barrel-shaped foundation mooring system and construction method thereof

A barrel-shaped foundation and mooring system technology, applied in the direction of infrastructure engineering, floating buildings, caisson, etc., can solve the problems of increasing the cost and construction difficulty of the foundation, increasing the size and quantity of the foundation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

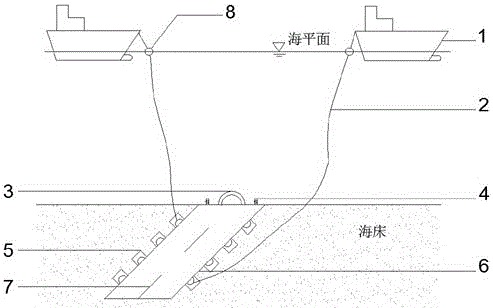

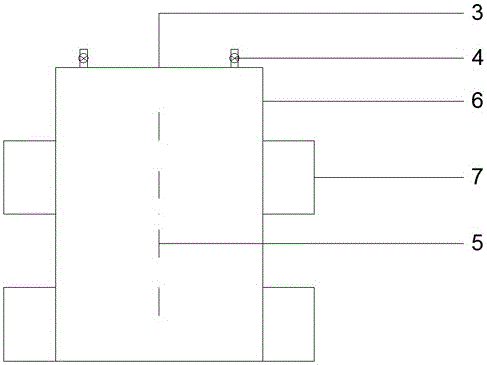

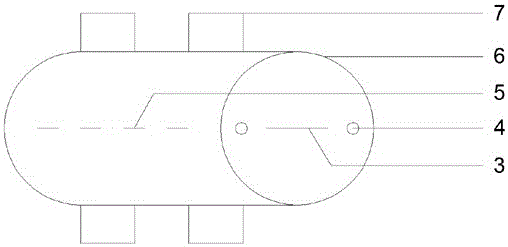

[0024] (1) When implementing the inclined barrel foundation mooring system, first use the anchor chain 2 to connect the anchor bolt 5 and the foundation ring 3 to fix the inclined barrel foundation 6; open the drain pipe 4, and connect the water pump to the drain pipe 4.

[0025] (2) On the seabed, position the inclined barrel-shaped foundation 6, firstly use the gravity of the foundation to penetrate into the seabed, and adjust the angle of the foundation.

[0026] (3) When the inclined barrel-shaped foundation 6 no longer falls under the action of its own weight, loosen the anchor chain 2, turn on the suction pump, and carry out suction penetration on the inclined barrel-shaped foundation 1 until the top cover of the foundation is flush with the seabed Turn off the drain switch and remove the sump pump.

[0027] (4) Install a buoy 8 on the upper part of the anchor chain 2, and connect the upper end of the anchor chain 2 with the floating structure 1 on the sea to be fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com