Pre-stressed anchor cable manual hole digging uplift pile and construction method thereof

A technology of prestressed anchor cables and manual hole-digging piles, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of low pile height, unsatisfactory pull-out resistance, and large-scale engineering accidents, etc. Achieve simple construction, improve the durability of the pile body, and enhance the durability of the pile body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

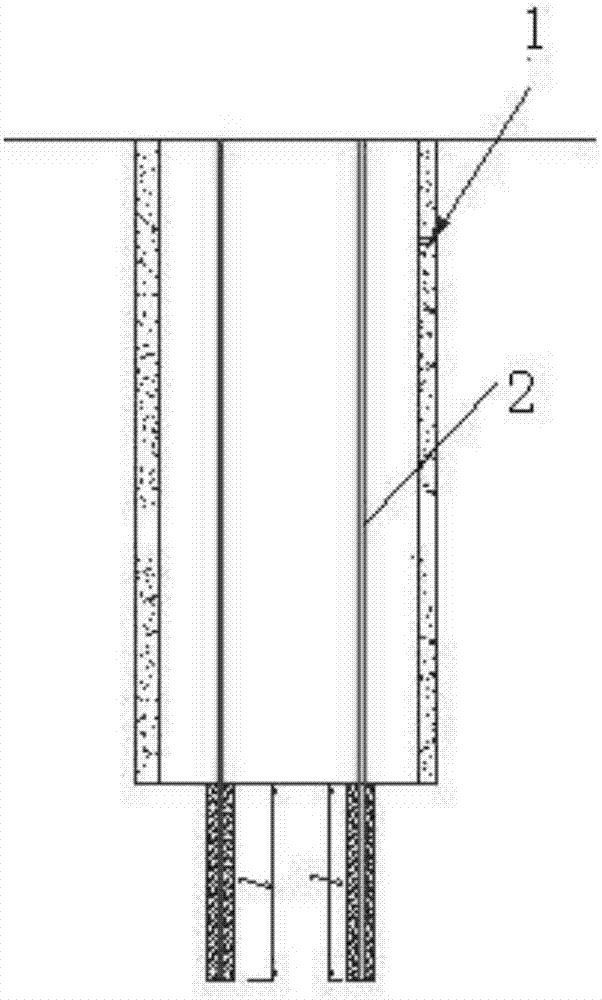

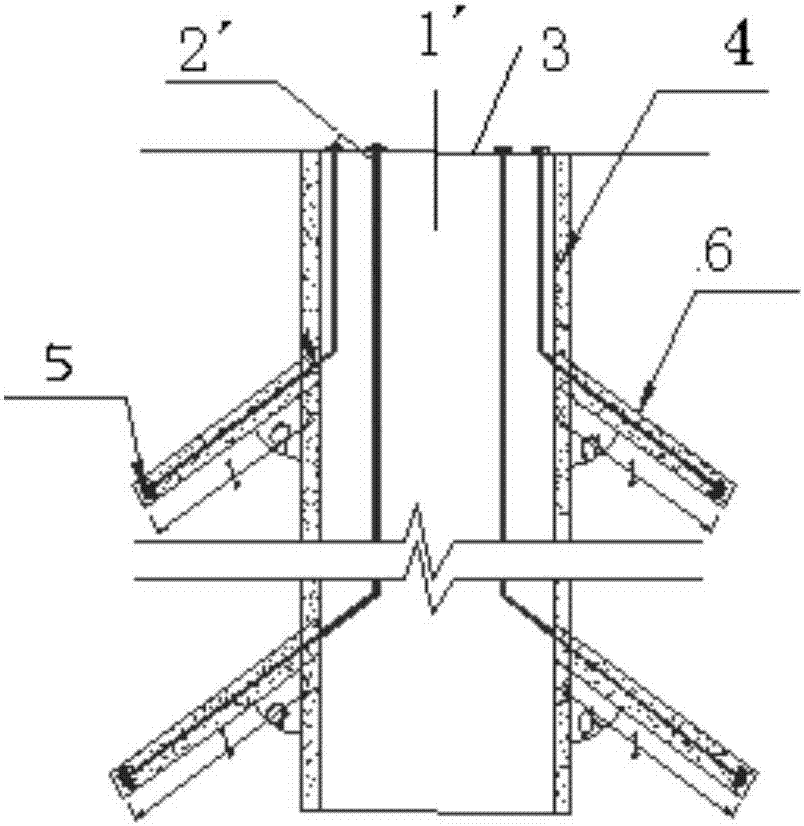

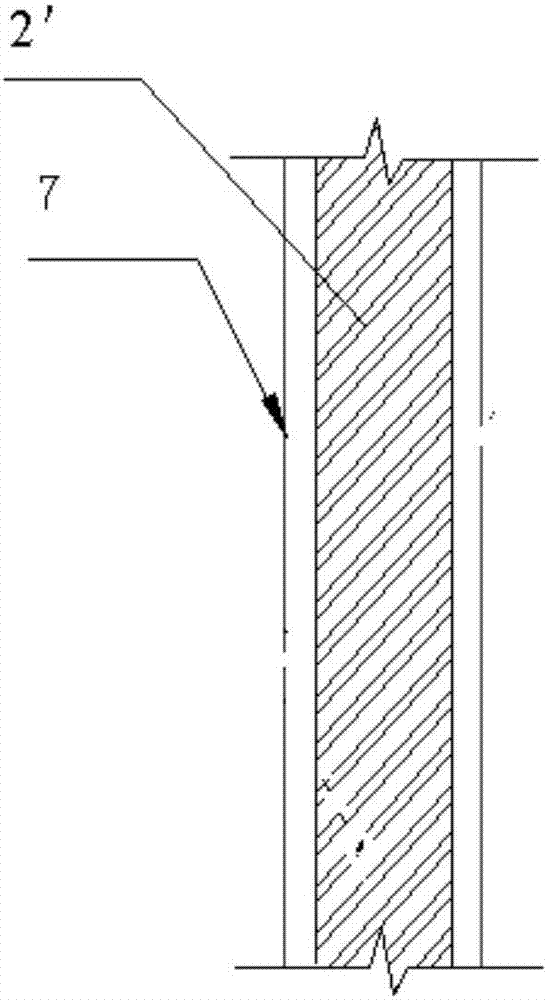

[0023] figure 1 It is the uplift pile in the prior art; figure 2 Schematic diagram of the cross-sectional structure of the present invention; image 3 It is a schematic enlarged view of the structure of the prestressed anchor cable and the isolation sleeve, as shown in the figure: the prestressed anchor cable artificially dug hole uplift pile in this embodiment includes a pile body 1' and a reinforced pile body 1' for axial uplift resistance More than one prestressed anchor cable 2', the prestressed anchor cable 2' is vertically arranged in the pile body 1', and the upper end is fixed to the pile head 3 of the pile body 1', and the lower end passes through the pile radially The side wall of the pile body 1' is anchored to the surrounding stratum of the pile body 1'; the prestressed anchor cable 2' forms an anchor section between the side wall 4 of the pile body 1' and the surrounding stratum, and concrete is poured on the pile body of the artificially excavated pile to reach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com