Assembled concrete pile cap and miniature pile combined foundation and construction method

A concrete and prefabricated technology, applied in infrastructure engineering, construction, etc., can solve problems such as difficulty in entering the site for large-scale pile foundation construction equipment, increase in earthwork excavation and support costs, and wet construction sites to achieve bonding The effect of strong force, uniform force and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

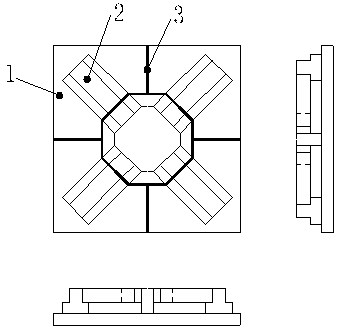

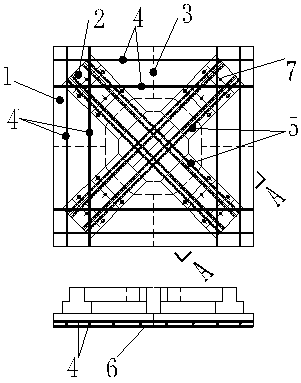

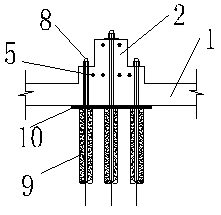

[0042] A prefabricated concrete cap and micro-pile joint foundation, which is divided into two parts, the lower part is a micro-grouting steel pipe pile 9, and the upper part is a prefabricated concrete cap, and the cap and the micro-grouting steel pipe pile 9 pass through the pile The steel bars in the body are anchored into the reserved holes 7 of the anchor bolts and then connected by grouting technology.

[0043] The micro-grouting steel pipe pile 9 adopts the pressure grouting process to form a pile, including the steel pipe and the pile structure fixed at the lower end of the steel pipe; the inner center of the steel pipe is arranged with a large-diameter high-strength threaded steel bar, and the threaded steel bar and the post-grouting body have strong adhesion and pull-out resistance The bearing capacity is high, and it is convenient to connect and fix through the nut on the top of the anchor bolt reserved hole 7.

[0044] The pile head of the micro-grouting steel pipe...

Embodiment 2

[0048] A construction method for a combined foundation of a prefabricated concrete cap and micropile, the specific steps are as follows:

[0049] (1) For foundation pit excavation, consider the prestressed tension construction operation space;

[0050] (2) For the construction of miniature steel pipe piles, the piles are connected by continuous welding method, and the steel pipe piles are pressed to the design depth;

[0051] (3) Adjust the elevation of the top of the micro-steel pipe pile, and ensure that the top of the micro-steel pipe pile is at the same elevation by adjusting the top sealing steel plate 10;

[0052](4) Positioning of the prefabricated concrete cap, use the rib insertion method to align and position the reserved hole 7 of the cap anchor bolt with the micro-steel pipe pile head hole; the positioning sequence of the five parts is to first locate the first corner unit (any one ) → Intermediate → Position the remaining three corner monomers in sequence (clockw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com