Detachable prefabricated assembly type steel-concrete composite beam and construction method thereof

A technology of prefabricated assembly and composite beams, applied to structural elements, building components, and long-strip structural components for load-bearing, etc., can solve problems such as difficult control of welding quality, complicated on-site construction, complex disassembly and repair, etc., and achieve high resistance Shearing, improving construction efficiency, high ductility and energy dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

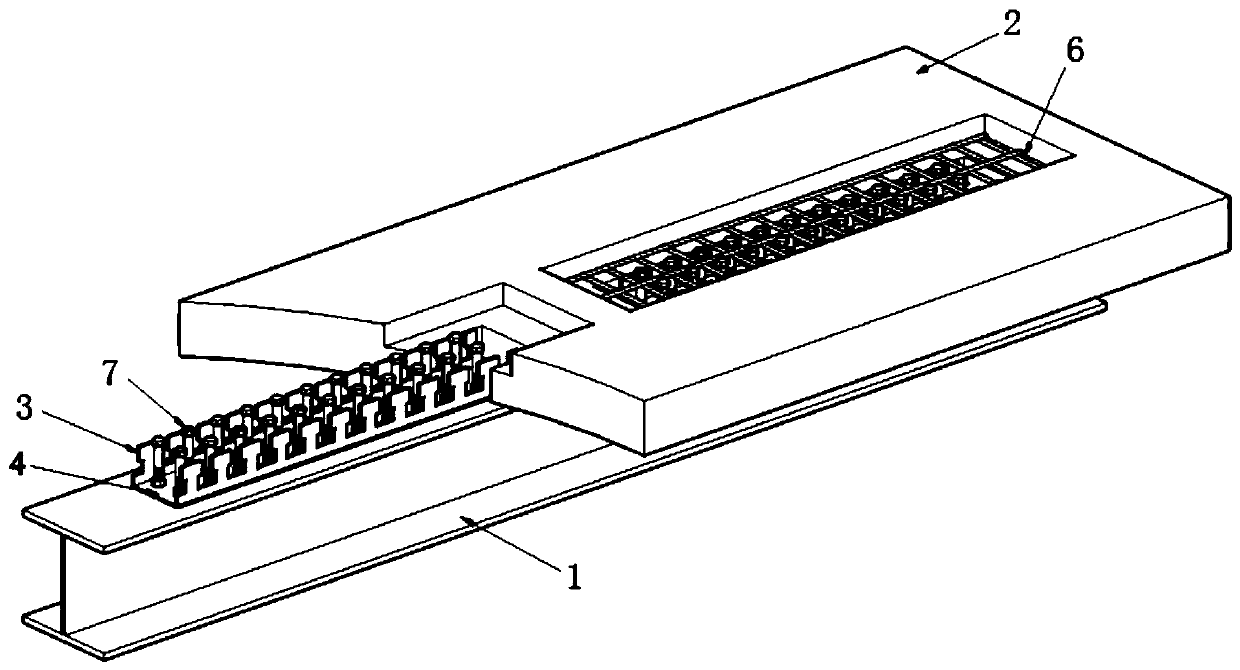

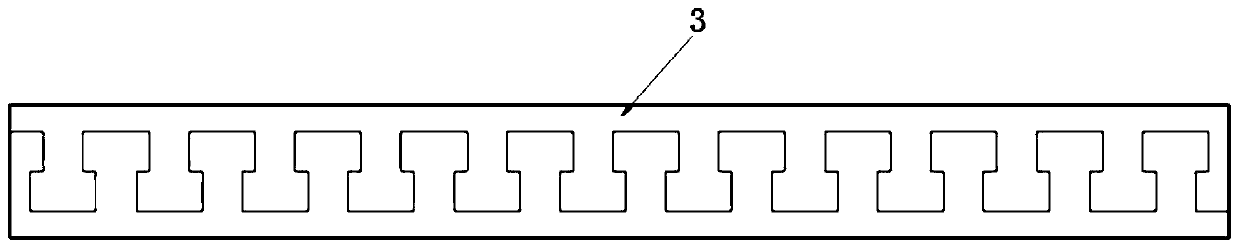

[0076] Such as figure 1 As shown, a detachable prefabricated steel-concrete composite beam includes a steel beam 1, a concrete slab 2, a concave-convex steel plate connector 3, and a spliced steel plate 4. Steel beam 1 is I-shaped steel or rectangular steel structure. Splicing steel plate 4 is arranged on the upper surface of steel beam 1. The two concave-convex steel plate connectors 3 are arranged on both sides of the spliced steel plate 4, and the two concave-convex steel plate connectors 3 and the spliced steel plate 4 form a "U" structure. A T-shaped shear notch 201 is provided in the middle of the concrete slab 2 . A concrete slab 2 is placed above the steel beam 1 . The two concave-convex steel plate connectors 3 and the spliced steel plate 4 form a "U"-shaped structure located in the T-shaped shear notch 201 of the concrete plate 2. In the T-shaped shear notch 201 of the concrete slab 2, the concrete layer is poured after the shear groove is poured.

[007...

Embodiment 2

[0079] Such as figure 1 , Figure 7 As shown, embodiment 1 is repeated, except that the composite beam also includes a lower reinforcement mesh 5 . The lower layer of steel mesh 5 is arranged in the T-shaped shear notch 201 of the concrete slab 2, and the concave-convex steel plate connector 3 passes through the lower layer of steel mesh 5, and the lower layer of steel mesh 5 contacts with the bottom of the concave-convex steel plate connector 3.

[0080] The composite beam also includes an upper reinforcement mesh 6 . The upper steel mesh 6 is set in the T-shaped shear notch 201 of the concrete slab 2, and the upper steel mesh 6 is located above the concave-convex steel plate connector 3, and the bottom surface of the upper layer steel mesh 6 is in contact with the top of the concave-convex steel plate connector 3.

[0081] The connection effect between the concave-convex steel plate connector and the post-cast concrete layer of the shear groove in the T-shaped shear notch ...

Embodiment 3

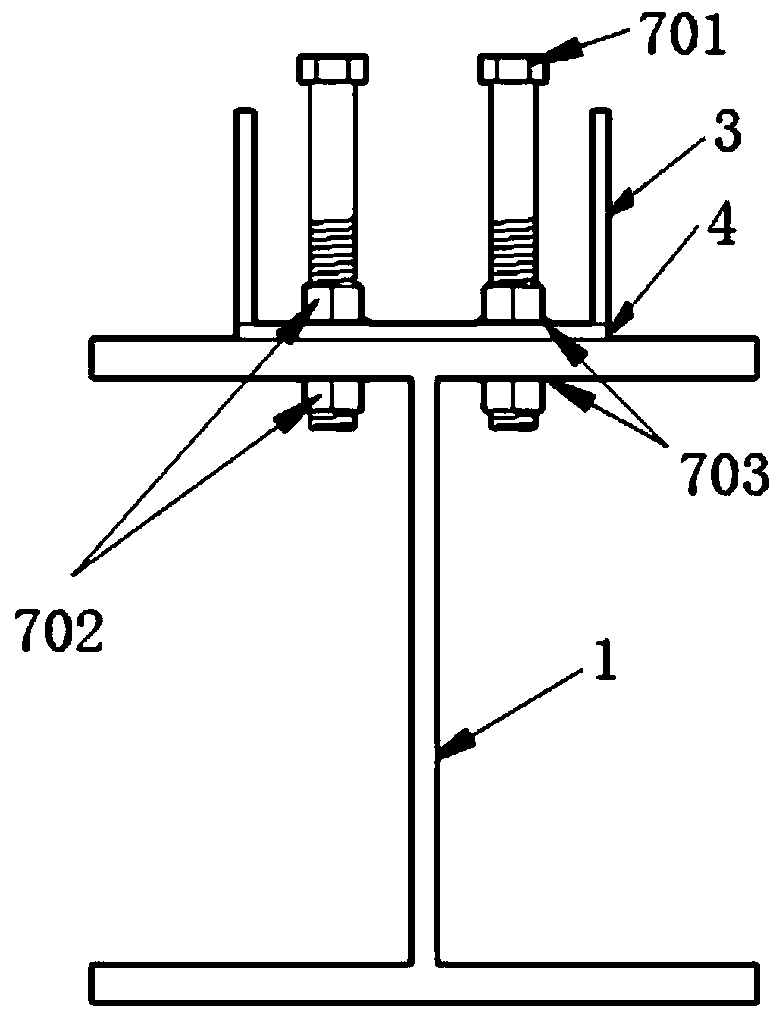

[0083] Such as figure 1 , image 3 As shown, Example 1 is repeated, and the upper surface of the steel beam 1 is provided with a steel beam connection hole 101 . The steel beam connection hole 101 runs through the upper surface of the steel beam 1 . The spliced steel plate 4 is provided with a steel plate connection hole 401 . The steel plate connection hole 401 runs through the spliced steel plate 4 . The spliced steel plate 4 is connected to the steel beam 1 through the steel beam connecting hole 101, the steel plate connecting hole 401 and bolts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com